High-carbon steel rod on-line aging high-speed production method

A production method and high-carbon steel technology, applied in the field of high-wire rolling steel, can solve problems such as poor results, and achieve the effects of increasing added value, enriching timeliness, and eliminating organizational stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

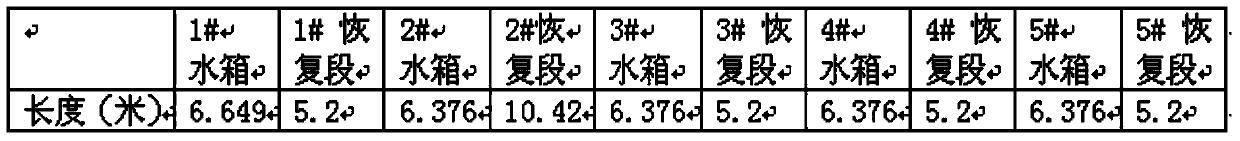

[0026] The present invention is applied in the 12.5mm specification 82B-1 developed by Shougang, and the process is as follows

[0027] (a) Four water tanks are used for water cooling after finishing rolling, the cooling temperature of each water tank is controlled at 23°C, and the spinning temperature is controlled at 905°C;

[0028] (b) The cooling rate of the wire rod after spinning is controlled at 11.7°C / s;

[0029] (c) The temperature of the heat preservation cover is 560°C, and the speed of the roller table in the heat preservation cover is controlled at 0.35m / s;

[0030] (d) The length of the heat preservation cover is 34m, and the heat preservation time of the heat preservation cover is controlled at 90s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com