An on-line aging device and processing method for hard-wired wire rods using pulsed magnetic fields

A pulsed magnetic field, hard wire technology, used in heat treatment furnaces, heat treatment equipment, furnace types, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

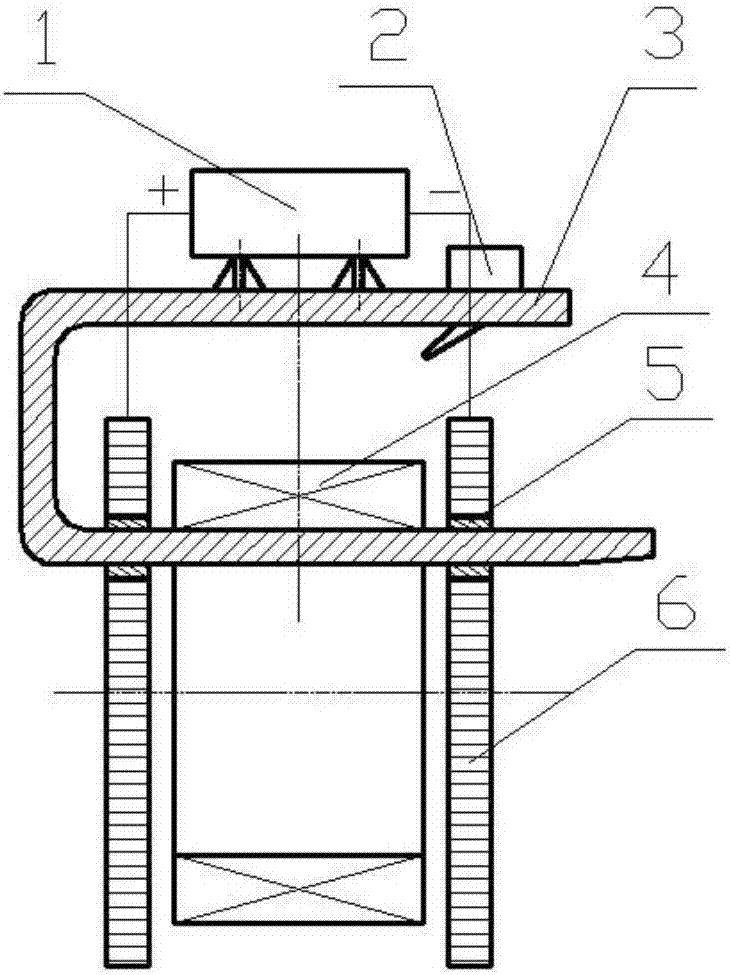

Embodiment 1

[0022] The hard line wire rod of this embodiment is SWRH82B, its specification is Φ8mm, chemical composition (mass fraction / %) is 0.82C, 0.26Si, 0.76Mn, 0.0010S, 0.0009P, 0.30Ni, 0.30Cr, and the rest is Fe. The coil is hung on the C-shaped hook on the special device proposed by the present invention in the transportation line after hot-rolling, spinning, cooling, and coil collection (note that before hanging, an induction coil has been installed on the C-shaped hook ), after which another induction coil is installed. The temperature control device starts to measure the temperature, and the temperature is displayed as 330°C (not lower than 300°C), and a signal is given to turn on the pulse power supply and start timing. The magnetic field strength in the control coil is 12000A / m, and the magnetic field frequency is 60Hz. When the C-shaped hook runs for 300s, disconnect the pulse power supply and the aging is over. After the C-shaped hook runs to the collection place, the induc...

Embodiment 2

[0026]The hard wire rod of this embodiment is SWRH77B, its specification is Φ12mm, chemical composition (mass fraction / %) is 0.78C, 0.22Si, 0.70Mn, 0.0009S, 0.0009P, 0.26Ni, 0.25Cr, and the rest is Fe. The coil is hung on the C-shaped hook on the special device proposed by the present invention in the transportation line after hot-rolling, spinning, cooling, and coil collection (note that before hanging, an induction coil has been installed on the C-shaped hook ), after which another induction coil is installed. The temperature control device starts to measure the temperature, the temperature is displayed as 350°C (not lower than 300°C), a signal is given to turn on the pulse power supply, and the timing starts. The magnetic field strength in the control coil is 15000A / m, and the magnetic field frequency is 80Hz. When the C-shaped hook runs for 420s, disconnect the pulse power supply and the aging is over. After the C-shaped hook runs to the collection place, the induction co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com