After-forged heat treatment technique of 9Cr2MoV chilled roll steel

A technology for post-forging heat treatment and cold rolling of roll steel, applied in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve problems that cannot be completely eliminated, roll cracking, cracking, etc., and achieve reduced deformation and cracking, uniform structure and hardness, high The effect of yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

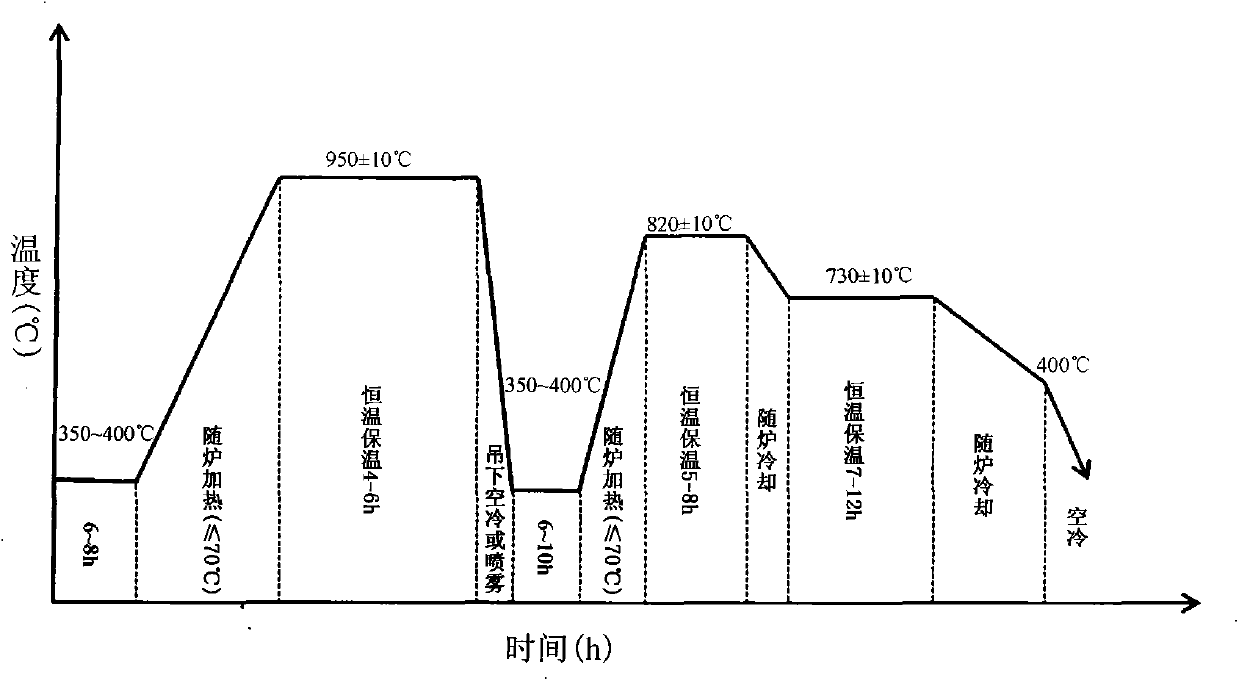

[0016] Embodiment 1, the post-forging heat treatment process of a kind of cold rolling roll is characterized in that: the material of the cold rolling roll is 9Cr2MoV steel, and its post-forging heat treatment method includes normalizing and spheroidizing annealing processes, and its heat treatment steps are as follows:

[0017] (1) Normalizing stage: After the cold roll forging is cooled to 350°C by spray water, it is heated to 950°C in a heat treatment furnace for 5 hours, and then hung down and sprayed with water to cool to 400°C.

[0018] (2) Spheroidizing and tempering stage: heat the cold roll cooled by sprayed water to 820°C in a heating furnace, cool to 730°C with the furnace after a holding time of 7 hours, and cool to 400°C with the furnace after a holding time of 10 hours. Then hang to air cool to room temperature.

Embodiment 2

[0019] Embodiment 2, the post-forging heat treatment process of a kind of cold rolling roll is characterized in that: the material of the cold rolling roll is 9Cr2MoV steel, and its post-forging heat treatment method includes normalizing and spheroidizing annealing process, and its heat treatment steps are as follows:

[0020] (1) Normalizing stage: After the cold roll forging is cooled to 450°C by sprayed water, it is heated to 960°C in a heat treatment furnace for 4 hours, and then hung down by sprayed water to cool to 400°C.

[0021] (2) Spheroidizing and tempering stage: heat the spray-cooled cold roll to 830°C in a heating furnace, cool it to 720°C with the furnace after a holding time of 4 hours, and cool it to 400°C with the furnace after a holding time of 8 hours, and then hang it Air cool to room temperature.

[0022] The microstructure and hardness obtained by the optimized post-forging heat treatment process are relatively uniform, which reduces the deformation and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com