Continuous long fiber reinforced PPS composite material and preparation method thereof

A composite material and long fiber technology, which is applied in the field of continuous long fiber reinforced PPS composite material and its preparation, can solve the problems of impeller rigidity to be improved, unsatisfactory toughening effect of PPS material, etc., and achieves light weight, high dimensional stability, Practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

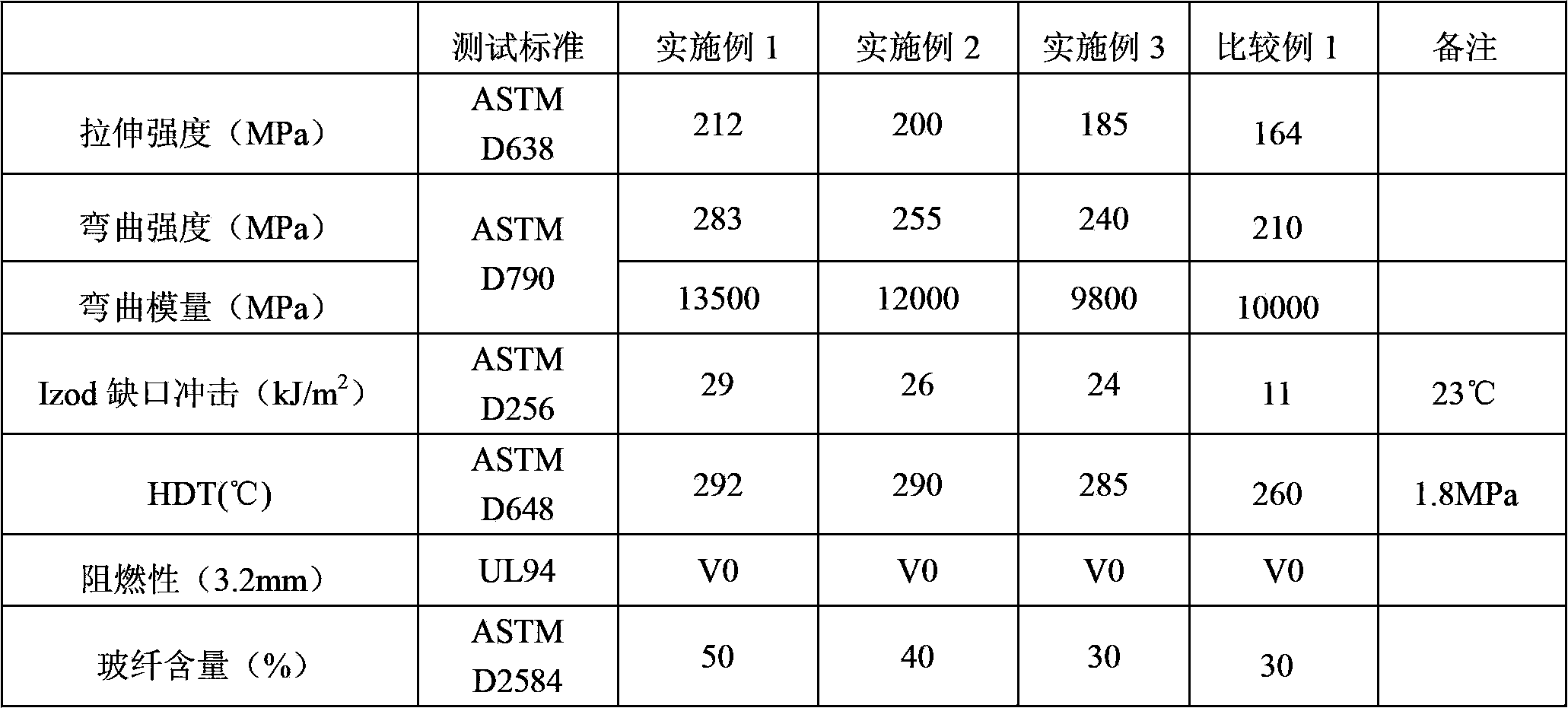

Embodiment 1

[0043](1) Weigh the raw materials of each component (in parts by weight) according to the following ratio, and dry the PPS: drying temperature: 120°C; drying time: 6h;

[0044] PPS 457 copies,

[0045] Continuous long fiber reinforcement 500 parts,

[0046] 8 parts of coupling agent,

[0047] 20 parts lubricant,

[0048] Antioxidant 15 parts,

[0049] The melting point of PPS resin is 280°C, the melt flow rate MFR (2.095mm, 315°C, 5.0Kg) is 240g / 10min; the continuous long fiber reinforcement is alkali-free continuous glass fiber, the fiber diameter is 17μm, and the linear density is 2400g / Km; The coupling agent is silane coupling agent KH550; the lubricant is silicone powder GM-100; the antioxidant is antioxidant 1098 (3,5-di-tert-butyl-4-hydroxyphenylpropionyl-hexanediamine) and antioxidant The compound system of agent PEPQ (tetra(2,4-di-tert-butylphenol)-4,4'-biphenyl diphosphite), the weight ratio of the two is 1:2;

[0050] (2) Mixing preparation:

[0051] Add the ab...

Embodiment 2

[0060] (1) Weigh the raw materials of each component (in parts by weight) according to the following ratio, and dry the PPS: drying temperature: 120°C; drying time: 6h;

[0061] PPS 557 copies,

[0062] Continuous long fiber reinforcement 400 parts,

[0063] 8 parts of coupling agent,

[0064] 20 parts lubricant,

[0065] Antioxidant 15 parts,

[0066] The melting point of PPS resin is 280°C, the melt flow rate MFR (2.095mm, 315°C, 5.0Kg) is 240g / 10min; the continuous long fiber reinforcement is alkali-free continuous glass fiber, the fiber diameter is 17μm, and the linear density is 2400g / km; The coupling agent is silane coupling agent KH550; the lubricant is silicone powder GM-100; the antioxidant is antioxidant 1098 (3,5-di-tert-butyl-4-hydroxyphenylpropionyl-hexanediamine) and antioxidant The compound system of agent PEPQ (tetra(2,4-di-tert-butylphenol)-4,4'-biphenyl diphosphite), the weight ratio of the two is 1:2;

[0067] (2) Mixing preparation:

[0068] Add the a...

Embodiment 3

[0077] (1) Weigh the raw materials of each component (in parts by weight) according to the following ratio, and dry the PPS: drying temperature: 120°C; drying time: 6h;

[0078] PPS 650 copies,

[0079] Continuous long fiber reinforcement 300 parts,

[0080] 8 parts of coupling agent,

[0081] 20 parts lubricant,

[0082] Antioxidant 15 parts,

[0083] The melting point of PPS resin is 280°C, the melt flow rate MFR (2.095mm, 315°C, 5.0Kg) is 240g / 10min; the continuous long fiber reinforcement is alkali-free continuous glass fiber, the fiber diameter is 17μm, and the linear density is 2400g / km; The coupling agent is silane coupling agent KH550; the lubricant is silicone powder GM-100; the antioxidant is antioxidant 1098 (3,5-di-tert-butyl-4-hydroxyphenylpropionyl-hexanediamine) and antioxidant The compound system of agent PEPQ (tetra(2,4-di-tert-butylphenol)-4,4'-biphenyl diphosphite), the weight ratio of the two is 1:2;

[0084] (2) Mixing preparation:

[0085] Add the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com