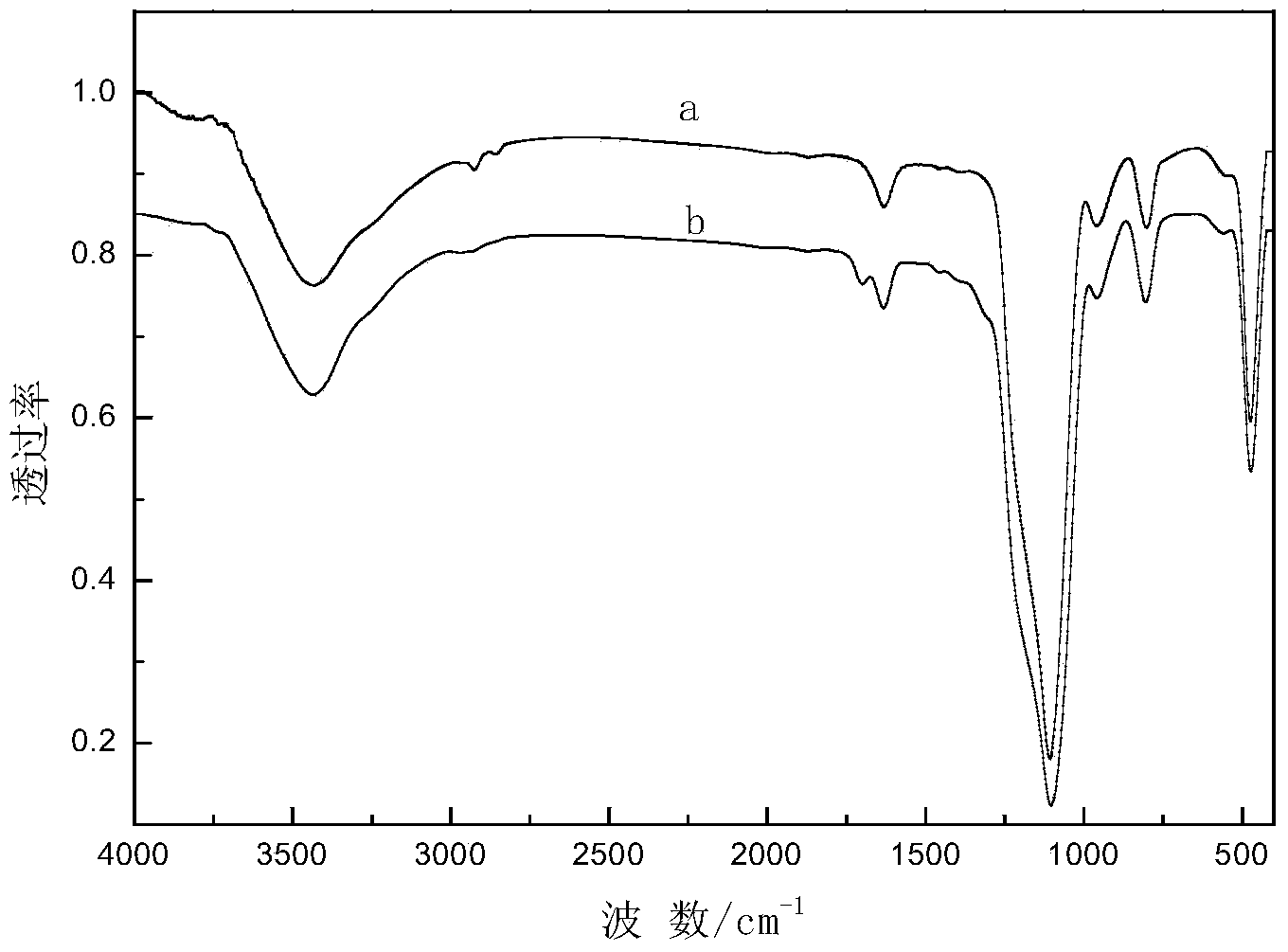

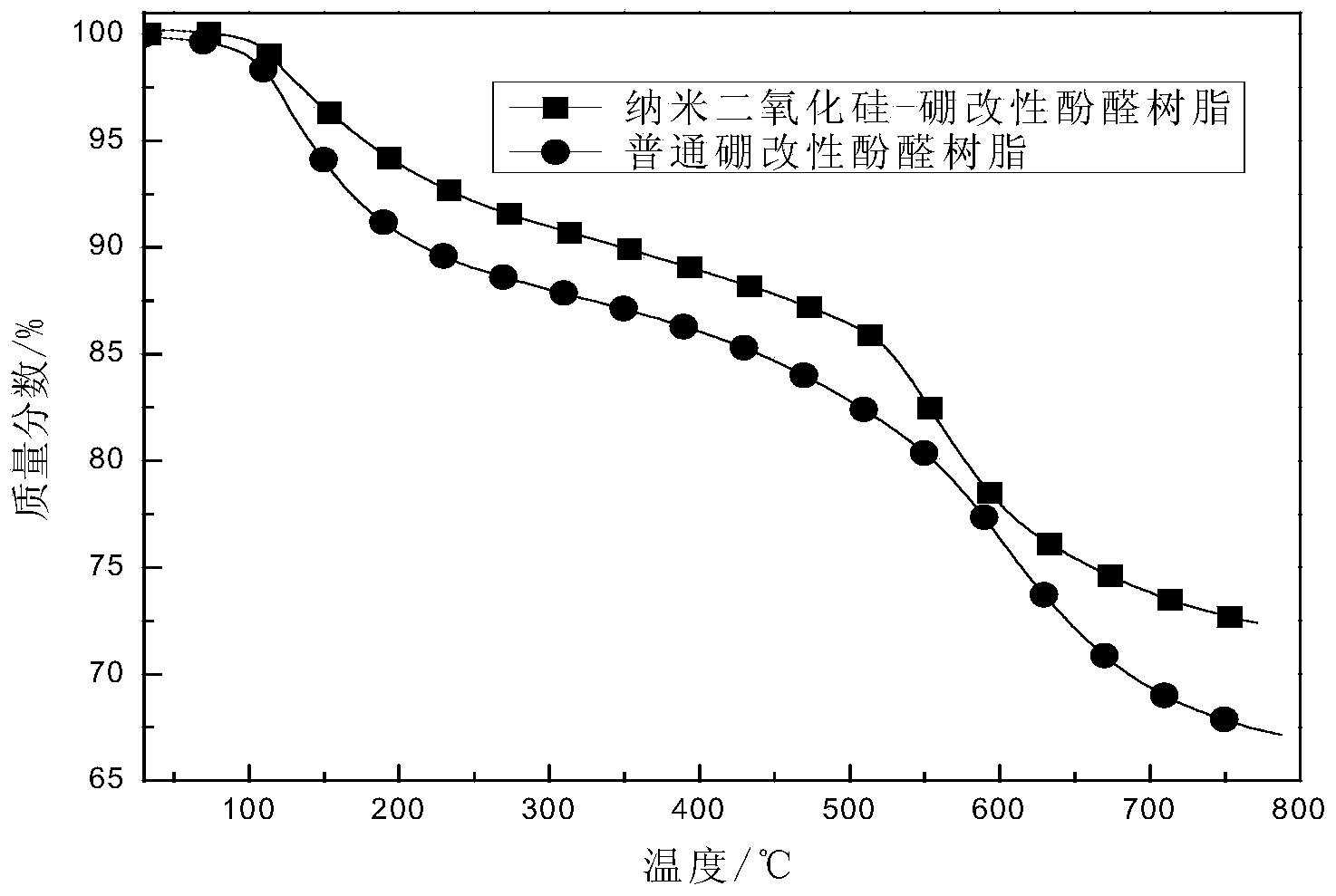

Method for preparing nano-silica-boron modified phenolic resin

A technology of nano-silica and phenolic resin, applied in the field of phenolic resin, can solve the problems of limited improvement of mechanical properties and achieve good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] One, the preparation of nano silica-boron modified phenolic resin:

[0027] The first step, nano-silica modification;

[0028] nano-SiO 2 Put it into an electric constant temperature blast drying oven and dry it at 60°C for 24h. Weigh 6g of nano-SiO 2 , pour it into a three-necked flask containing a mixed solution of absolute ethanol and deionized water, and ultrasonically disperse for 1 hour; take 1.2g of silane coupling agent γ-methacryloxypropyltrimethoxysilane (KH-570) Dissolve in the mixed solution of oxalic acid solution with pH 3.5 and absolute ethanol, stir it magnetically for 1 hour, pour it into a three-necked flask that has been ultrasonicated, and stir at 85°C for 5 hours. Finally, the obtained emulsion was washed with a mixed solution of absolute ethanol and deionized water, centrifuged at 15° C. and 10,000 rpm for 15 minutes, and repeated 3 times to remove excess silane coupling agent γ-methacryloxypropyltrimethoxysilane ( KH-570) and by-products, and ...

Embodiment 2

[0043] One, the preparation of nano silica-boron modified phenolic resin:

[0044] The first step, nano-silica modification;

[0045] nano-SiO 2 Put it into an electric constant temperature blast drying oven and dry it at 60°C for 24h. Weigh 6g of nano-SiO 2 , pour it into a three-necked flask containing a mixed solution of absolute ethanol and deionized water, and ultrasonically disperse for 1 hour; take 0.6g of silane coupling agent γ-methacryloxypropyltrimethoxysilane (KH-570) Soluble in the mixed solution of oxalic acid solution with a pH of about 3.5 and absolute ethanol with a volume ratio of 1:1, and then pour it into a three-necked flask that has completed ultrasonication at one time after magnetic stirring for 1 hour, and react at a constant temperature of 85°C for 5 hours . Finally, the obtained emulsion was washed with a mixed solution of absolute ethanol and deionized water, centrifuged at 10° C. and 12000 rpm for 20 min, and repeated 3 times to remove excess s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| carbon residual rate | aaaaa | aaaaa |

| carbon residual rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com