Slice resin grinding wheel and preparation method thereof

A technology for resin grinding wheels and thin slices, which is applied in the direction of manufacturing tools, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of hardness, unsatisfactory self-sharpening, brittle crack damage of thin slice grinding wheels, and low cutting efficiency, etc., to achieve enhanced Self-sharpening, high cutting size accuracy and fast cutting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

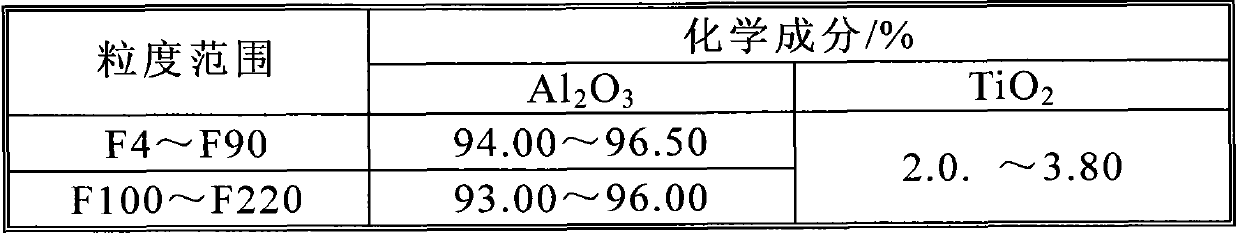

[0033] like figure 1 As shown, first weigh 33 parts of white corundum, 68 parts of microcrystalline corundum, 10 parts of green silicon carbide, 7 parts of phenolic resin solution, 20 parts of phenolic resin powder, 10 parts of cryolite powder, and 12 parts of pyrite powder.

[0034] Then put the white corundum, microcrystalline corundum and green silicon carbide into the phenolic resin solution for infiltration, and then mix the phenolic resin powder, cryolite powder and pyrite powder with the infiltrated white corundum, microcrystalline corundum and green silicon carbide evenly.

[0035] The mixed raw material granules are sieved through a sieve to select granules with a particle size of 8-12 meshes as molding materials for molding.

[0036] Take the molding material needed to make three thin-slice resin grinding wheels, or weigh the molding material needed for another thin-slice resin grinding wheel after filling one. Pour the molding material required for half of the shee...

Embodiment 2

[0039] like figure 1 As shown, first weigh 30 parts of white corundum, 70 parts of microcrystalline corundum, 15 parts of green silicon carbide, 8 parts of phenolic resin solution, 19 parts of phenolic resin powder, 15 parts of cryolite powder, and 10 parts of pyrite powder.

[0040] Then put the white corundum, microcrystalline corundum and green silicon carbide into the phenolic resin solution for infiltration, and then mix the phenolic resin powder, cryolite powder and pyrite powder with the infiltrated white corundum, microcrystalline corundum and green silicon carbide evenly.

[0041] The mixed raw material granules are sieved through a sieve to select granules with a particle size of 8-12 meshes as molding materials for molding.

[0042] Take the molding material needed to make three thin resin grinding wheels, or weigh the molding material needed for another grinding wheel after filling one. Pour the molding material required for half of the sheet resin grinding wheel ...

Embodiment 3

[0045] like figure 1 As shown, first weigh 35 parts of white corundum, 65 parts of microcrystalline corundum, 5 parts of green silicon carbide, 7 parts of phenolic resin solution, 22 parts of phenolic resin powder, 12 parts of cryolite powder, and 15 parts of pyrite powder.

[0046] Then put the white corundum, microcrystalline corundum and green silicon carbide into the phenolic resin solution for infiltration, and then mix the phenolic resin powder, cryolite powder and pyrite powder with the infiltrated white corundum, microcrystalline corundum and green silicon carbide evenly.

[0047] The mixed raw material granules are sieved through a sieve to select granules with a particle size of 8-12 meshes as molding materials for molding.

[0048] Weigh the molding material needed to make three thin-slice resin grinding wheels, or weigh the molding material needed for another thin-slice resin grinding wheel after filling one. Pour the molding material required for half of the shee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com