Upper surface antireflective film forming composition and pattern forming method using same

A technology of antireflection film and composition, which is applied in the field of upper antireflection film forming composition and composition of antireflection film, can solve problems such as practical difficulties, and achieve the effect of sufficient film formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1~25

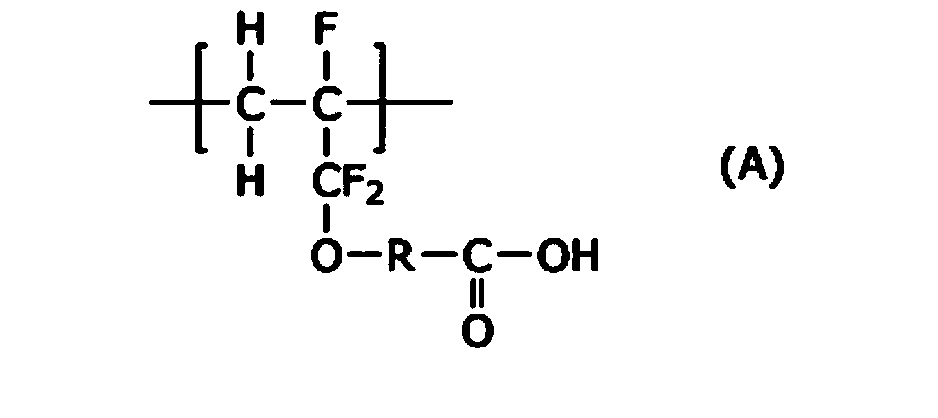

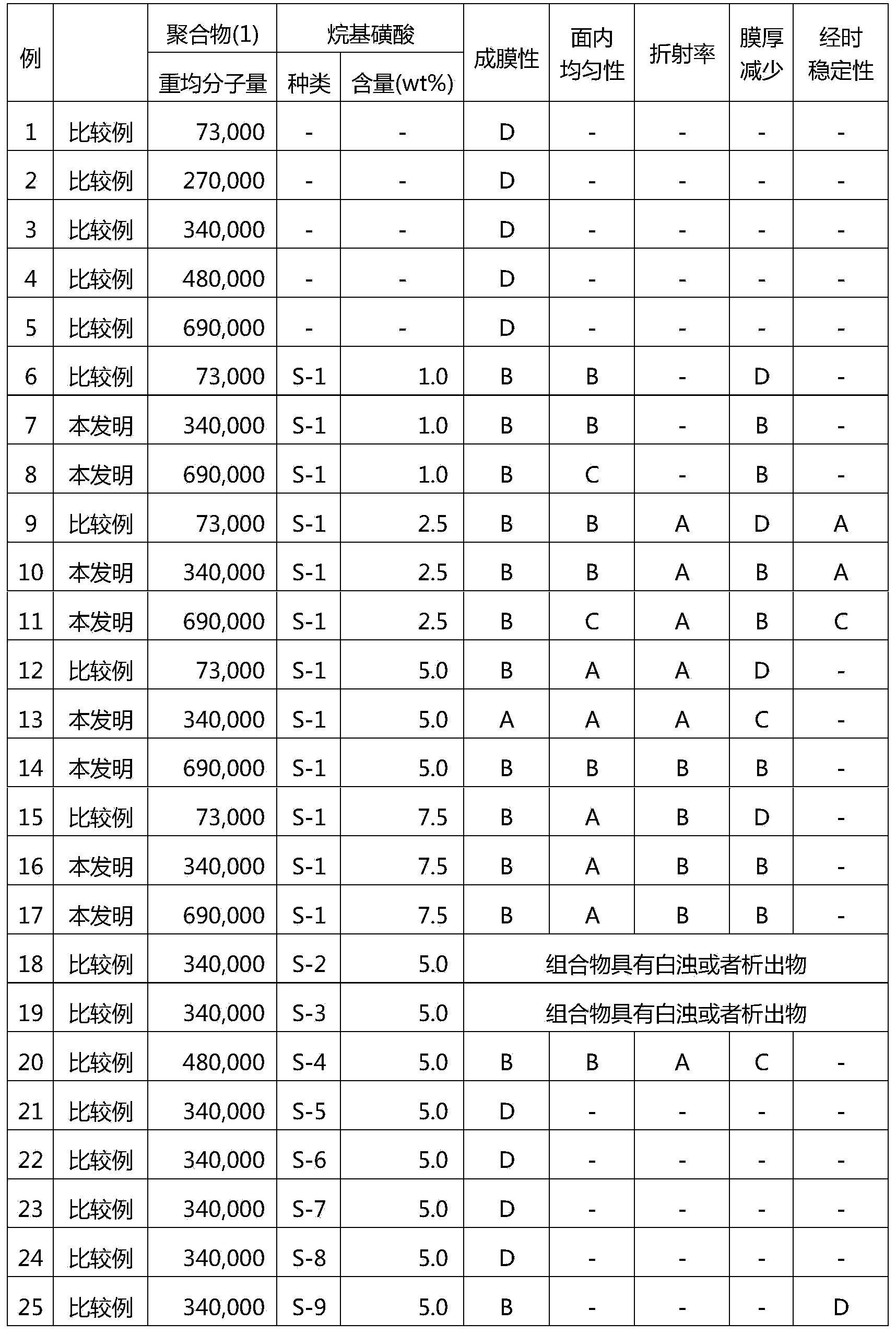

[0094] Fluoropolymers having different weight-average molecular weights represented by the general formula (1) are prepared, and the polymer, alkylsulfonic acid, or a surfactant used as a comparison object is dissolved in water as a solvent to prepare the upper surface resistance. Composition for forming a reflective film. Alternatively, in alkyl sulfonic acids or surfactants, use:

[0095] S-1: Alkane sulfonic acid mixture with 10 to 18 carbon atoms

[0096] S-2: Ethylene oxide adduct of acetylene diol (Surfynol 485 (trade name), manufactured by Air Products Limited.), nonionic surfactant

[0097] S-3: Polyoxyethylene lauryl amino ether (D-3110-P (trade name), manufactured by Takemoto Oil Co., Ltd.), nonionic surfactant

[0098] S-4: Alkyl diphenyl ether sulfonic acid mixture with an average carbon number of 12

[0099] S-5: Ethanesulfonic acid

[0100] S-6: Octanesulfonic acid

[0101] S-7: Camphorsulfonic acid

[0102] S-8: p-toluenesulfonic acid

[0103] S-9: dodecy...

example 26~31

[0120] A composition for forming an upper surface antireflective film containing a fluoropolymer represented by general formula (1) and having a weight average molecular weight of 340,000, alkylsulfonic acid S-1 or S-4, and various amine compounds was prepared. Here, the contents of the polymer, the alkylsulfonic acid, and the amine compound were set to 2.0% by weight, 0.1% by weight, and 0.2% by weight, respectively, based on the total weight of the composition. Using these compositions, the same evaluation as Examples 1-25 was performed. The results obtained are shown in Table 2. In addition, examples 13 and 20 in Table 1 are also shown together for reference.

[0121] Table 2

[0122]

[0123] From these results, it can be seen that the composition for forming an antireflective film on the upper surface of the present invention tends to improve film-forming properties and in-plane uniformity as compared with compositions containing conventional surfactants regardless o...

example 32~37

[0125] A composition for forming an upper surface antireflection film containing a fluoropolymer represented by the general formula (1) and having a weight average molecular weight of 340,000, an additional polymer, and alkylsulfonic acid S-1 was prepared. Here, as the additional polymer, polyacrylic acid P-1 (weight average molecular weight: 5,000) or polyvinylpyrrolidone P-2 (polymerization average molecular weight: 5,000) was used. The total polymer content and the alkylsulfonic acid content were set to 2.0% by weight and 0.1% by weight, respectively, based on the total weight of the composition. In addition, the compounding ratio of a fluorine-containing polymer and an additional polymer is shown in Table 3. Using these compositions, the same evaluation as Examples 1-25 was performed. However, a resist composition for i-line (MiR703 (trade name), manufactured by AZ Electronic Materials Inc.) was used for evaluation of film thickness reduction. The obtained results are sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com