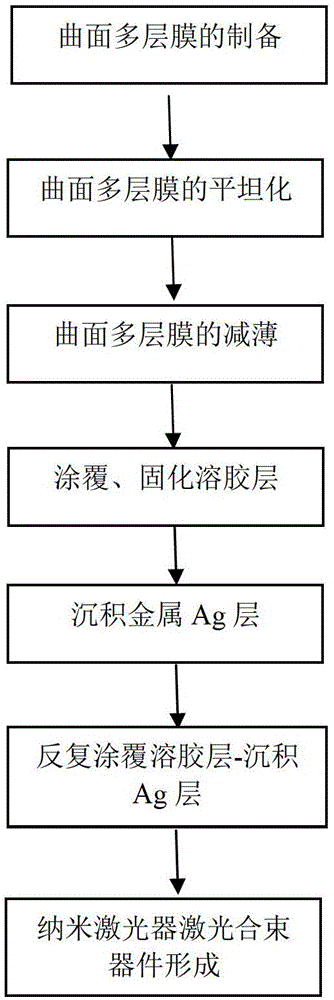

Preparation method of a nano-laser laser beam combining device

A nano-laser and laser beam combining technology, which is applied in nano-optics, nano-technology, nano-technology, etc., can solve problems such as limited laser power, and achieve the effects of compact structure, improved laser power, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1, such as figure 1 As shown, a nanolaser laser beam combining device is prepared on a curved surface groove with a diameter depth of 200nm, and the specific implementation steps are as follows:

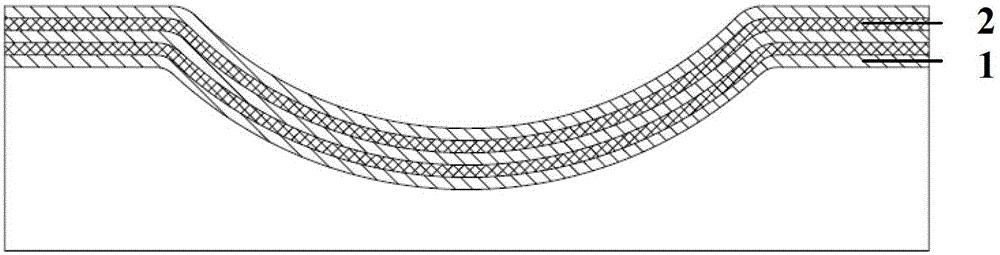

[0032] (1) Deposit a curved multilayer film structure on a curved groove. Metal Ag and dielectric SiO are alternately deposited by magnetron sputtering deposition 2 , in which the metal Ag is deposited by DC sputtering with a DC power of 120w; the dielectric SiO 2 Radio frequency sputtering is used for deposition, and the deposition power is 200w. The film thickness of each layer is 20nm. A total of 10 groups of 20 layers were deposited, with a total film thickness of 400nm, such as figure 2 Shown; 1 represents metal Ag; 2 represents silicon dioxide.

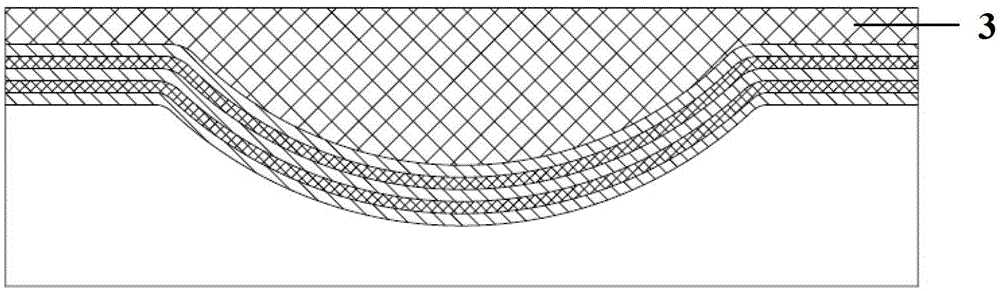

[0033] (2) Planarization is carried out by coating AZ-3100 photoresist, the rotation speed is 4000rpm, the spin coating time is 40s, and baked on a hot plate at 120°C for 1h. The glue thickness is 1000nm, such as ...

Embodiment 2

[0038] Embodiment 2, in such as figure 1 As shown, a nanolaser laser beam combining device is prepared on a curved surface groove with a diameter depth of 250 nm, and the specific implementation steps are as follows:

[0039] (1) Deposit a curved multilayer film structure on the prepared curved groove. Deposition by evaporation coating, alternate deposition of metal Ag and dielectric SiO 2 , where the metal Ag is deposited by thermal evaporation, and the dielectric SiO 2 Deposited by electron beam evaporation. The film thickness of each layer is 30nm. A total of 8 groups of 16 layers were deposited, with a total film thickness of 480nm, such as figure 2 Shown; 1 represents metal Ag; 2 represents silicon dioxide.

[0040] (2) Planarization is carried out by coating AR-P3120 photoresist sol layer, the rotation speed is 5000rpm, the suspension coating time is 40s, and baked on a hot plate at 100°C for 1h. The glue thickness is 600nm, such as image 3 Shown; 3 represents t...

Embodiment 3

[0045] Example 3, such as figure 1 As shown, a nanolaser laser beam combining device is prepared on a curved surface groove with a diameter depth of 300nm, and the specific implementation steps are as follows:

[0046] (1) Deposit a curved multilayer film structure on a curved groove. Magnetron sputtering was used to deposit metal Ag and medium SiO2 alternately, wherein metal Ag was deposited by DC sputtering with a DC power of 120w; medium SiO2 was deposited by radio frequency sputtering with a deposition power of 200w. The film thickness of each layer is 15nm. A total of 20 groups of 40 layers were deposited, with a total film thickness of 600nm, such as figure 2 Shown; 1 represents metal Ag; 2 represents silicon dioxide.

[0047] (2) Planarization is carried out by coating AR-P3170 photoresist, the rotation speed is 2000rpm, the spin coating time is 40s, and the coating is repeated 5 times. Bake on a hot plate at 120 °C for 1 h. The glue thickness is 600nm, such as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com