Integrated circuit packaging structure and packaging method thereof

A packaging structure and integrated circuit technology, applied in the direction of circuits, electrical components, electric solid devices, etc., can solve the problem that can not take into account device heat dissipation and air tightness at the same time. Problems such as heat dissipation methods and the inability of heat dissipation devices to establish heat dissipation channels to achieve the effect of meeting high reliability requirements, ensuring impact resistance requirements, and ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

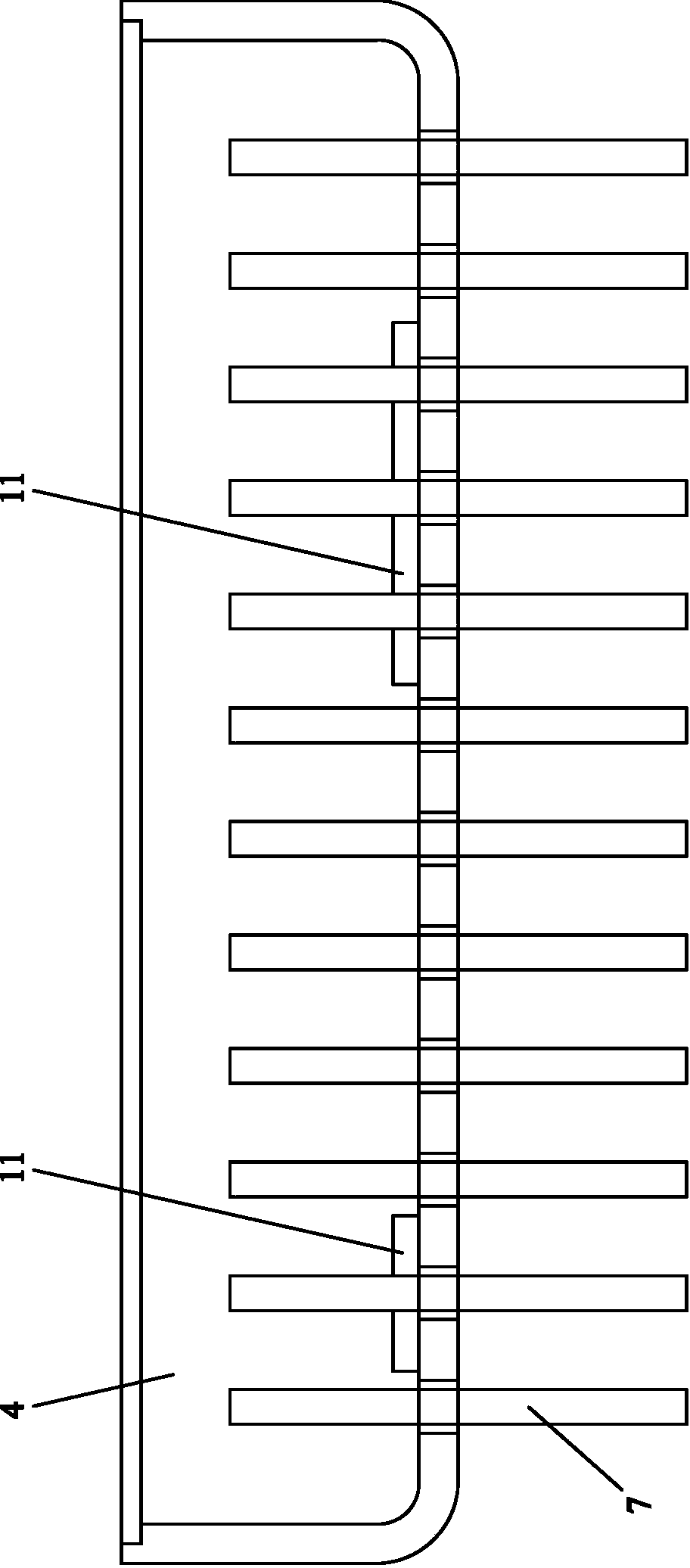

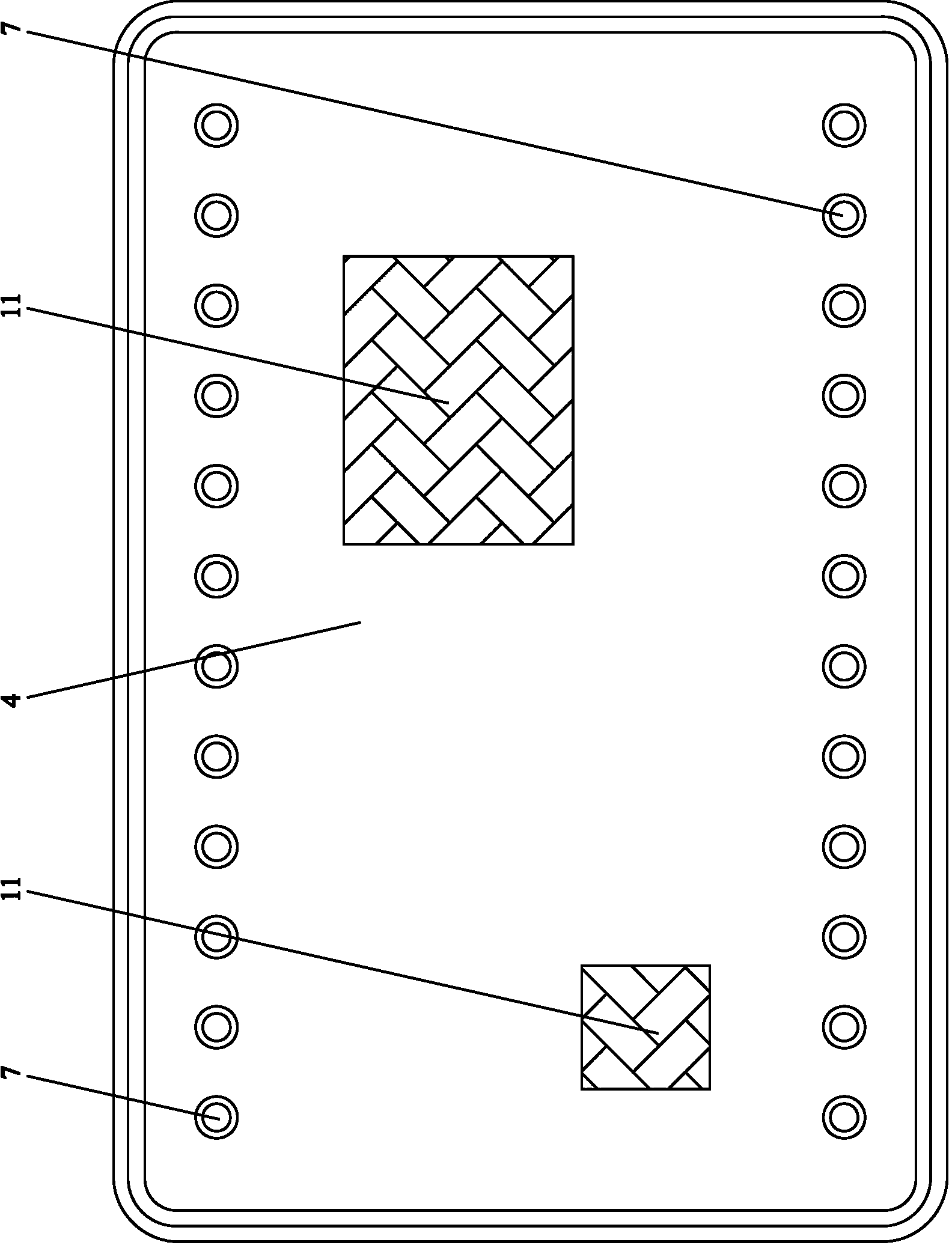

[0033] Embodiment one: see attached figure 1 shown. An integrated circuit packaging structure includes a metal casing 1 and a substrate 2 installed in the metal casing 1 and having surface mount devices 14 and bare chips 15 arranged on both sides. Substrate 2 is made of beryllium oxide, Al 2 o 3 Or PCB and other materials that can be used as circuit substrates, have a certain resistance to mechanical impact, and have the characteristics of general material selection. The surface-mount device 14 and the bare chip 15 have heat-generating devices 3 (ie, power devices) that require heat dissipation paths to be designed in the packaging structure.

[0034] The metal casing 1 includes a casing base 4 and a casing cover 5, wherein the casing base 4 is a box-shaped structure with an upward opening, and the casing cover 5 covers the opening, so that the casing base 4 A complete metal casing 1 is formed with the casing cover plate 5 and an inner cavity 6 is formed, and the substrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com