Package structure of winding type solid electrolytic capacitor using lead frame and manufacturing method thereof

A technology of solid-state electrolysis and packaging structure, which is applied in the direction of solid electrolytic capacitors, capacitor casings/packaging, capacitor parts, etc., can solve problems such as the limitation of electrical connection methods of wound-type solid electrolytic capacitors, and achieve improved welding yield and improved Effect of Equivalent Series Resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

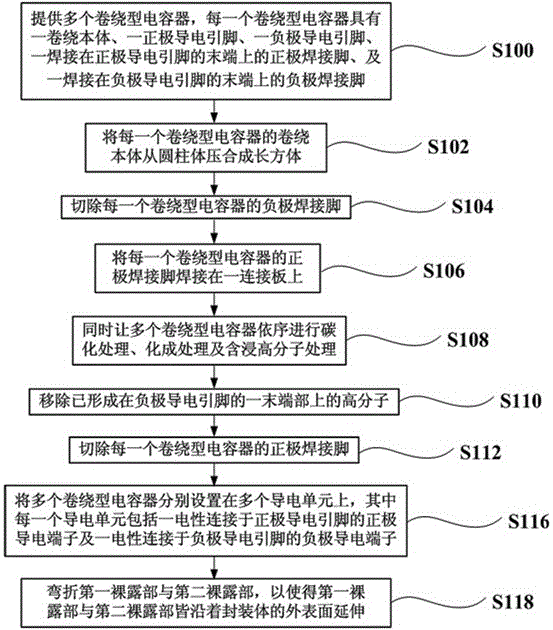

[0056] see Figure 1 to Figure 8 As shown, the present invention provides a method for manufacturing a wound-type solid electrolytic capacitor packaging structure Z using a lead frame, which at least includes the following steps:

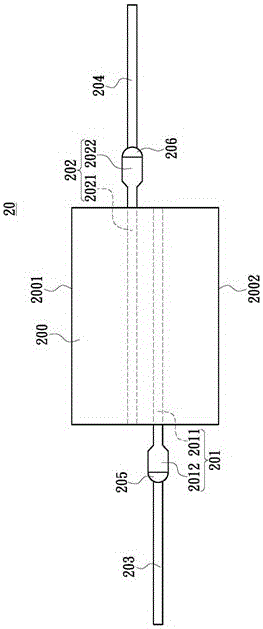

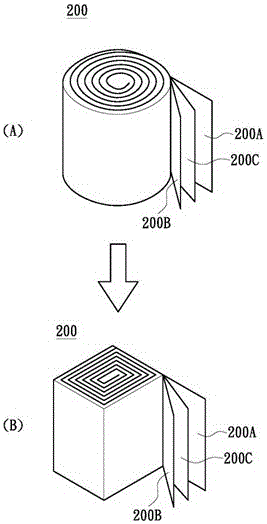

[0057] First, cooperate figure 1 and figure 2As shown, a plurality of wound capacitors 20 are provided, wherein each wound capacitor 20 has a wound body 200, a positive conductive pin 201 extending from one side of the wound body 200, a A negative electrode conductive pin 202 extending from the other side of the winding body 200, a positive electrode welding leg 203 welded on the end of the positive electrode conductive pin 201, and a negative electrode welded on the end of the negative electrode conductive pin 202 Solder the pin 204 (step S100). Furthermore, the positive conductive pin 201 and the negative conductive pin 202 can respectively extend from two opposite side ends of the winding body 200 . In addition, the positive welding leg 203 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com