Method for improving welding performance of copper surface heat sink for packaging shell after gold plating

A technology for encapsulation and welding performance, applied in the field of surface treatment, to achieve the effect of improving welding performance, no environmental pollution, welding performance and welding yield improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

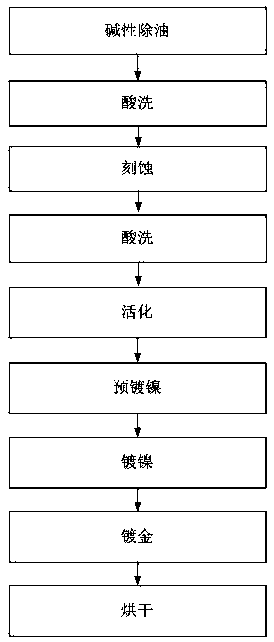

[0039] A method for improving soldering performance after gold-plated copper surface heat sink for encapsulation shell, comprising the following steps:

[0040] ① Alkaline degreasing: Alkaline degreasing is an aqueous solution, which contains 40 g / L chemical degreasing powder. Put the brazed semi-finished product shell into the alkaline degreasing solution at 60 ° C for 5 minutes, and use tap water after degreasing Rinse and rinse with deionized water;

[0041] ② Pickling: The pickling solution is an aqueous solution, which contains: 5mL / L OP emulsifier, 75g / L thiourea, and 100mL / L sulfuric acid. Put the washed shell into the pickling solution at 60°C for 5 minutes. After pickling, rinse with tap water first, and then clean with deionized water;

[0042] ③ Etching: The etching solution is an aqueous solution, which contains: 100mL / L pickling agent A, 200mL / L pickling agent B, 10mL / L oxidizing agent, 20g / L corrosion inhibitor, and the temperature of the solution is 40°C , soa...

Embodiment 2

[0050] A method for improving soldering performance after gold-plated copper surface heat sink for encapsulation shell, comprising the following steps:

[0051] ① Alkaline degreasing: Alkaline degreasing is an aqueous solution, which contains 60 g / L chemical degreasing powder. Put the brazed semi-finished shell in an alkaline degreasing solution at 80°C for 15 minutes. After degreasing, use tap water first. Rinse and rinse with deionized water;

[0052] ② Pickling: The pickling solution is an aqueous solution, which contains: 10mL / L OP emulsifier, 150g / L thiourea, and 200mL / L sulfuric acid. Put the washed shell into the pickling solution at 80°C for 15 minutes. After pickling, rinse with tap water first, and then clean with deionized water;

[0053] ③ Etching: The etching solution is an aqueous solution, which contains: 300mL / L pickling agent A, 400mL / L pickling agent B, 50mL / L oxidizing agent, 60g / L corrosion inhibitor, and the temperature of the solution is 60°C , soak the...

Embodiment 3

[0061] A method for improving soldering performance after gold-plated copper surface heat sink for encapsulation shell, comprising the following steps:

[0062] ① Alkaline degreasing: Alkaline degreasing is an aqueous solution, which contains 50 g / L chemical degreasing powder. Put the brazed semi-finished shell in the alkaline degreasing solution at 70 ° C for 10 minutes, and then use tap water after degreasing Rinse and rinse with deionized water;

[0063] ②Pickling: The pickling solution is an aqueous solution, which contains: 8mL / L OP emulsifier, 110g / L thiourea, and 150mL / L sulfuric acid. Put the washed shell into the pickling solution at 70°C for 10 minutes. After pickling, rinse with tap water first, and then clean with deionized water;

[0064] ③ Etching: The etching solution is an aqueous solution, which contains: 200mL / L pickling agent A, 300mL / L pickling agent B, 30mL / L oxidizing agent, 40g / L corrosion inhibitor, and the temperature of the solution is 50°C , soak t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com