A method for manufacturing a large-diameter wear-resistant and corrosion-resistant ternary composite pipe

A ternary composite and manufacturing method technology, applied in the direction of pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve the problems of perforation of steel pipes, deformation of pipe straightness and roundness, etc., to achieve small deformation, tight bonding and smoothness smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

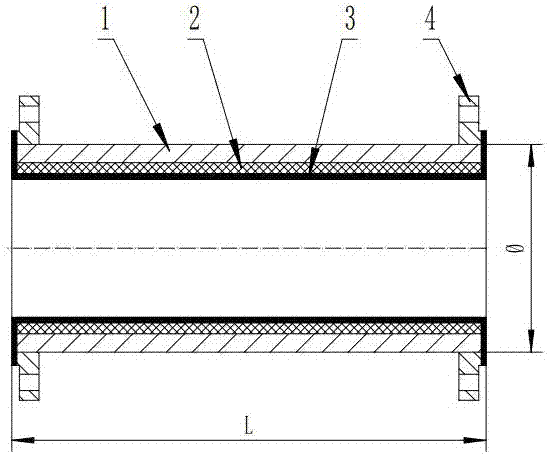

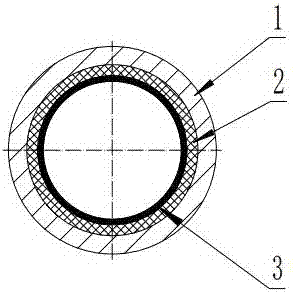

[0035] Example 1: This method is used to make DN1000 length 6000 ternary composite pipes (unspecified length units are mm, the same below)

[0036] a. Application of self-propagating high-temperature centrifugal synthesis reaction (SHS) to produce large-diameter ceramic composite steel pipes

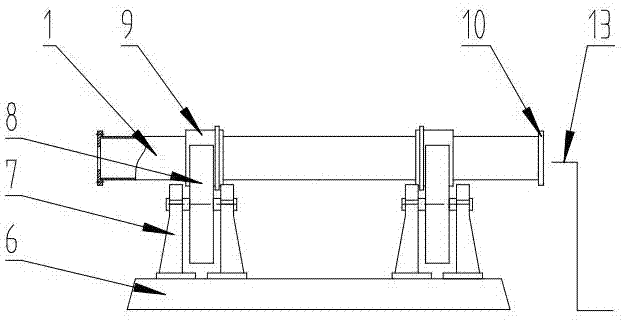

[0037] This large-diameter steel pipe is made of steel plate, with an outer diameter of 1020, a wall thickness of 12, and a length of 2000. The butt joint is automatically welded. (Such as Figure 7 ), the steel pipe butt joint is placed at the butt joint gap between the upper and lower casings.

[0038] Install the cover at both ends, the cover is closely attached to the steel pipe, and fixed firmly with bolts.

[0039] Prepare thermite, with the ratio of iron oxide powder 56%, aluminum powder 21%, zirconia powder 8%, titanium oxide powder 4%, silicon oxide powder 3%, aluminum oxide powder 3%, boron oxide 5%, etc. Prepare 137kg of reaction raw materials, mix them evenly, add them int...

Embodiment 2

[0045] Example 2: This method is used to make a ternary composite pipe with a length of DN600 and a length of 4000 (unspecified length units are mm, the same below)

[0046] a. Application of self-propagating high-temperature centrifugal synthesis reaction (SHS) to produce large-diameter ceramic composite steel pipes

[0047] This large-diameter steel pipe is made of steel plate, with an outer diameter of 630mm, a wall thickness of 12mm, and a length of 2000mm. (Such as Figure 7 ), the steel pipe butt joint is placed at the butt joint gap between the upper and lower casings.

[0048] Install the cover at both ends, the cover is closely attached to the steel pipe, and fixed firmly with bolts.

[0049] Prepare thermite, with the ratio of iron oxide powder 56%, aluminum powder 19%, zirconia powder 8%, titanium oxide powder 5%, silicon oxide powder 3%, aluminum oxide powder 4%, boron oxide 5%, etc. Prepare 86kg of reaction raw materials, mix them evenly, add them into a large-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com