Antisplash oil inlet mechanism

An anti-splash and oil intake technology, used in mechanical equipment, engine components, machines/engines, etc., can solve the problem that the oil pump is susceptible to fuel shock, and achieve the effects of improving adhesion resistance, prolonging service life and reducing conveying resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

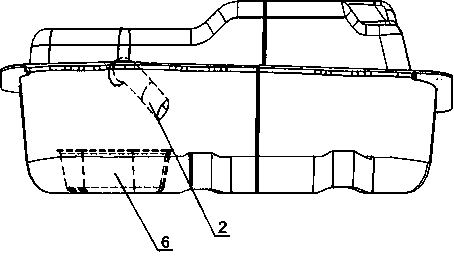

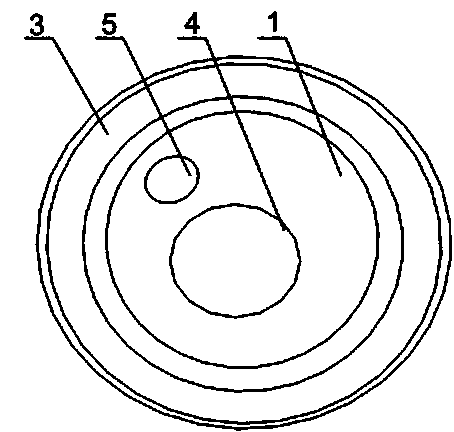

[0020] Such as figure 1 As shown, this embodiment includes an oil guide pipe and an oil suction groove 6, the end of the oil guide pipe is placed in the oil suction groove 6, the oil guide pipe includes an oil pipe 2 and an oil outlet 3, and a spacer 1 is installed in the oil outlet 3, and the spacer 1 Placed at the junction of the oil outlet 3 and the oil pipe 2, the spacer 1 is provided with an oil outlet 4 and an adjustment hole 5, the oil outlet 4 is flanged to the side close to the oil pipe 2, and the oil pipe 2 is arc-shaped. There is an oil suction groove 6 in the fuel tank, and the oil inlet 3 of the fuel pump is placed in the oil suction groove 6. The fuel flows into the oil suction groove 6 quickly through the oil guide pipe. There is a certain impact between the groove 6 and the oil inlet of the fuel pump; the spacer 1 installed in the oil outlet 3 can play the role of buffering the rapid flow of fuel and impacting the oil outlet 3 and the fuel pump inlet, and the o...

Embodiment 2

[0022] Such as figure 1 As shown, on the basis of Embodiment 1, this embodiment also includes a coating arranged on the inner wall of the spacer 1 and the oil pipe 2. The fuel oil impacts the inner wall of the spacer 1 or the oil pipe 2 for a long time, and the spacer 1 or The inner wall of oil pipe 2 is easy to be damaged. Installing a coating on the inner wall of spacer 1 or oil pipe 2 can greatly increase the delivery volume or reduce the pressure of oil pipe 2, or reduce the attachment of spacer 1 to ensure smooth passage of fuel. Increase economic benefits.

[0023] As preferably, the coating is a mixture of solvent-free modified epoxy resin and ceramic microbeads and a mixture of ceramic microbeads, solvent-free modified epoxy resin is used as the film-forming substance of the coating, and ceramic microbeads are used as fillers, which can effectively Improve the anti-adhesion of the coating, improve the smoothness of the inner wall of the oil pipe 2, reduce the conveyin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com