Improved electric contact structure, and relay and switch using same

An electrical connector, relay technology, applied in electromagnetic relays, electromagnetic relay details, relays, etc., can solve the problems of Ni segregation, difficult to obtain contact resistance, difficult and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

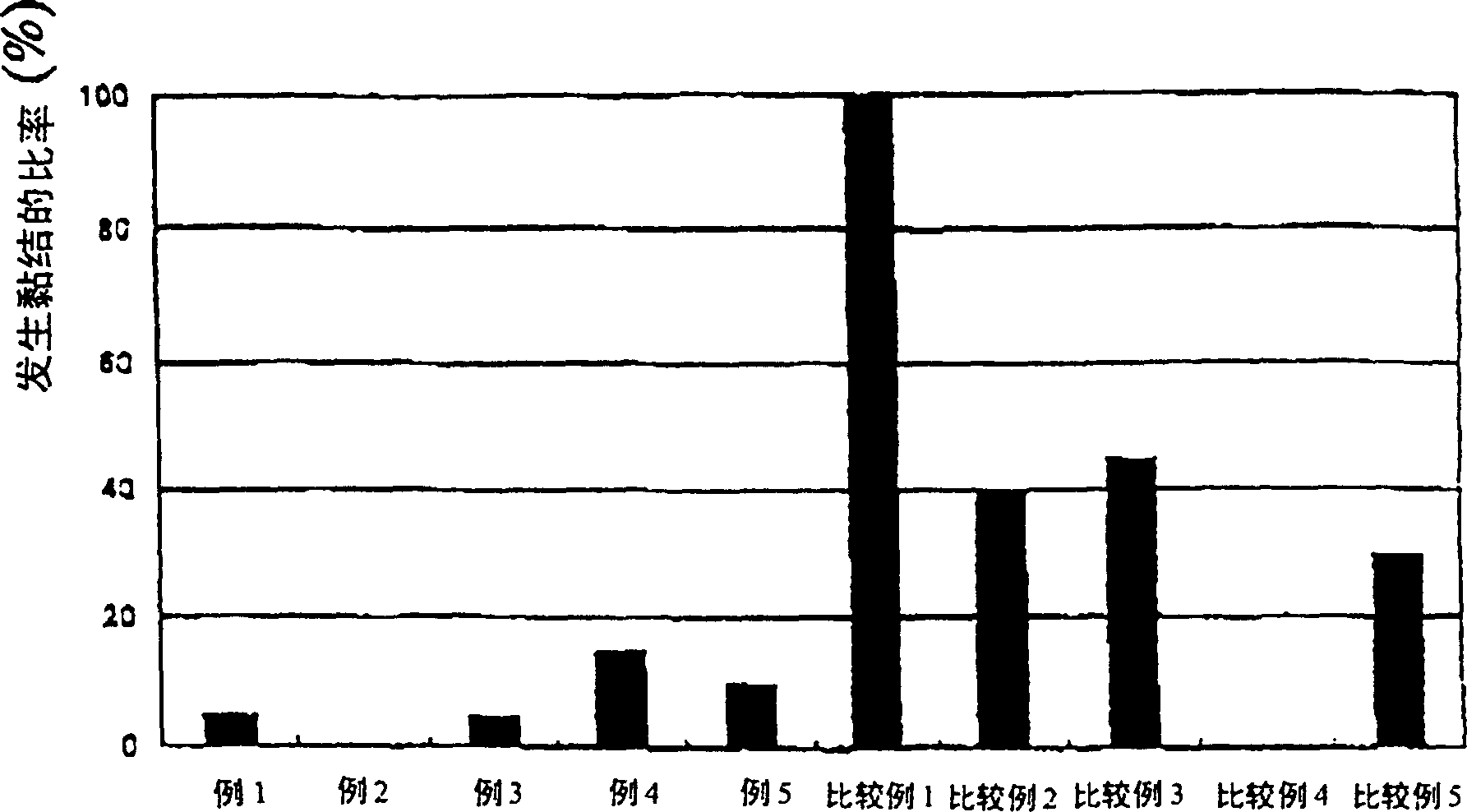

example 1

[0049] In this example, the moveable break joint has a moveable break contact surface layer consisting of Au 82 Ag 15 PD 3 alloy, while the fixed break joint has a fixed break contact surface layer, which also has Au 82 Ag 15 PD 3 alloy. Au 82 Ag 15 PD 3 The composition ratio of the alloy was 82% by weight of Au, 15% by weight of Ag, and 3% by weight of Pd.

example 2

[0051] In this example, the moveable break joint has a moveable break contact surface layer consisting of Au 76 Ag 15 PD 9 alloy, while the fixed break joint has a fixed break contact surface layer, which also has Au 76 Ag 15 PD 9 alloy. Au 76 Ag 15 PD 9 The composition ratio of the alloy was 76% by weight of Au, 15% by weight of Ag, and 9% by weight of Pd.

example 3

[0053] In this example, the moveable break joint has a moveable break contact surface layer consisting of Au 86 Ag 8 PD 6 alloy, while the fixed break joint has a fixed break contact surface layer, which also has Au 86 Ag 8 PD 6 alloy. Au 86 Ag 8 PD 6 The composition ratio of the alloy was 86% by weight of Au, 8% by weight of Ag, and 6% by weight of Pd.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com