Pre-purification method before sublimation and purification of OLED (organic light emitting diode) material

A pre-purification, pure water technology, applied in organic chemical methods, chemical instruments and methods, hydrocarbon purification/separation, etc., can solve problems such as low recovery rate, unstable quality, process defects, etc., to improve efficiency and facilitate industrialization Production, the effect of reducing the workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

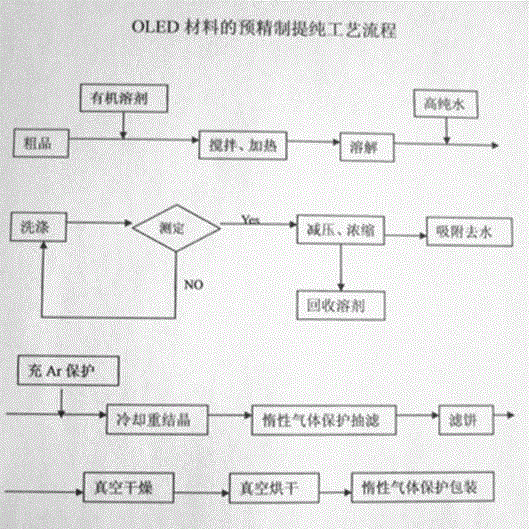

Method used

Image

Examples

Embodiment 1

[0045] Pre-purification of 9-(2-naphthyl)-10-[4-(1-naphthyl)phenyl]anthracene (NNPA) compound:

[0046] Step a:

[0047] In the there-necked flask, add NNPA crude product 100g, add tetrachloroethane 1500ml, start stirring, and heat; When stirring 2h, when the temperature rose to 105 ° C, the NNPA crude product was all dissolved, and kept this temperature and stirred for 30min.

[0048] Step b:

[0049] When the temperature drops to room temperature, pour the solution into a separatory funnel, add 1000ml of high-purity water, stir and wash for 10 minutes, let stand for 10 minutes, and separate the liquid; then add 1000ml of high-purity water, stir and wash for 10 minutes, stand for 10 minutes, and separate the liquid; repeat this again 7 times; from the 7th time onwards, the resistivity of the washing solution was continuously measured at the level of 8.5 MΩ·cm.

[0050] step c:

[0051] Under the protection of inert gas Ar, the solution obtained in step b was dehydrate...

Embodiment 2

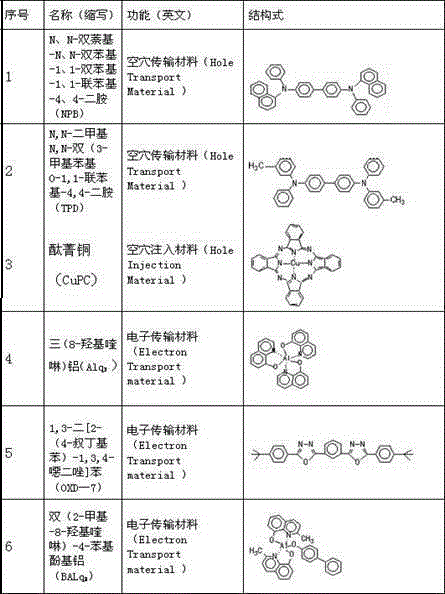

[0055] Pre-purification of N, N-bisnaphthyl-N, N-bisphenyl-1, 1-bisphenyl-1, 1-biphenyl-4, 4-diamine (NPB) compounds:

[0056] The prepurification process is the same as Example 1, except that the NNPA raw material in step a is replaced by NPB, and tetrachloroethane is replaced by dichloromethane, the mass volume ratio of NPB / dichloromethane is 1 / 12, and other steps are similar , will not be repeated.

Embodiment 3

[0058] Pre-refining and purification of 2, 9-dimethyl-4, 7-diphenyl-1, 10-phenyline (BCP) compounds:

[0059] The prepurification process is the same as in Example 1, except that the NNPA raw material in step a is replaced by BCP, tetrachloroethane is replaced by chloroform, and the mass volume ratio of NNPA / tetrachloroethane is replaced by 1 / 15 The mass-volume ratio of BCP / trichloromethane is 1 / 10, and other steps are similar and will not be repeated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com