High-performance silicon/graphene oxide negative electrode material based on chemical bond and preparation method thereof

A graphene negative electrode, high-performance technology, applied in the direction of nanotechnology for materials and surface science, battery electrodes, structural parts, etc., can solve the problems that the electrochemical performance needs to be further improved, to prevent falling off or agglomeration, and improve cycle The effect of lifespan and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

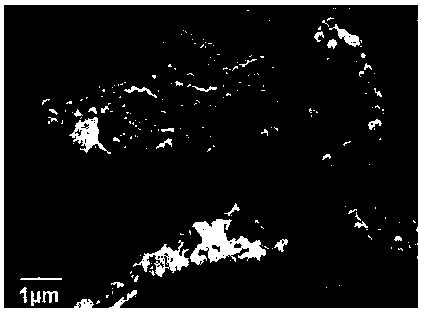

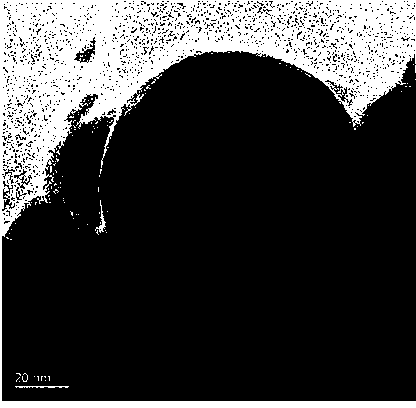

Image

Examples

Embodiment 1

[0026] first step: Add 100 mg of nano-silica powder into 100 ml of concentrated hydrochloric acid (36%wt), ultrasonically disperse for 20 minutes, and magnetically stir in an oil bath at 50 °C, where the stirring speed is 300 rpm and the stirring time is 4 hours. The silicon powder activated by concentrated hydrochloric acid was collected by filtration, washed three times with deionized water, washed once with alcohol, and dried under vacuum at 80 °C overnight. Dissolve 1 g of aminopropyltriethoxysilane in 200 ml of toluene, and stir magnetically at room temperature for 5 hours (200 rpm) to fully dissolve. Take 100 mg of silicon powder activated by hydrochloric acid and add it to the prepared surfactant solution, ultrasonically disperse for 50 minutes, and condense and reflux at 110 ° C for 24 hours. Finally, the modified silica powder was collected by filtration, washed with deionized water and dried under vacuum at 60 °C overnight.

[0027] Step two: Add 100 mg of modif...

Embodiment 2

[0030] first step: Add 70 mg of nano-silica powder into 100 ml of concentrated hydrochloric acid (38%wt), ultrasonically disperse for 30 minutes, and magnetically stir in an oil bath at 70°C, where the stirring speed is 200 rpm and the stirring time is 3 hours. The silicon powder activated by concentrated hydrochloric acid was collected by filtration, washed three times with deionized water, washed once with alcohol, and dried under vacuum at 65° C. overnight. Dissolve 1 g of aminopropyltrimethoxysilane in 200 ml of toluene, and stir magnetically at room temperature for 3 hours (200 rpm) to fully dissolve it. Take 70 mg of silicon powder activated by hydrochloric acid and add it to the prepared surfactant solution, ultrasonically disperse for 40 minutes, and condense and reflux at 150 ° C for 3 hours. Finally, the modified silica powder was collected by filtration, washed with deionized water and dried under vacuum at 65 °C overnight.

[0031] Step two: Basically the same...

Embodiment 3

[0034] first step: Add 800 mg of submicron silicon powder into a mixed solution of 100 mL of concentrated hydrochloric acid (38%wt) and 25 mL of 20%wt hydrogen peroxide solution, ultrasonically disperse for 60 minutes, and stir magnetically in an oil bath at 30°C, where the stirring speed 500 rev / min, stirring time is 1 hour. The silicon powder activated by concentrated hydrochloric acid was collected by filtration, washed three times with deionized water, washed once with alcohol, and dried in vacuum at 100 °C overnight. 0.2 g of dopamine was dissolved in 100 ml of alcohol-deionized water mixed solution, and magnetically stirred at room temperature for 2 hours (200 rpm) to allow it to fully dissolve. Take 800 mg of silicon powder activated by hydrochloric acid and add it to the prepared surfactant solution, ultrasonically disperse for 15 minutes, and condense and reflux at 65 °C for 40 hours. Finally, the modified silica powder was collected by filtration, washed with deio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com