LED (Light Emitting Diode) chip manufacturing technology, LED chip structure and LED chip packaging structure

A LED chip and manufacturing process technology, which is applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve the problems of large difference in expansion coefficient of GaN silicon, high cost, and easy cracking, so as to optimize the packaging structure design and prevent deformation. Yellow, high reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

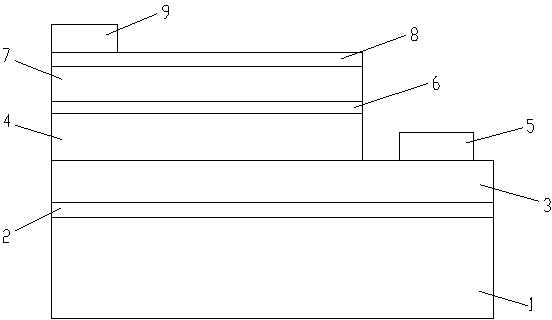

[0021] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

[0022] In the manufacturing process of the LED chip of the present invention, tungsten-molybdenum-copper alloy (WMoCu) is used as the substrate instead of commonly used sapphire and silicon carbide materials as the substrate. The weight percentage of tungsten in the tungsten-molybdenum-copper alloy is 84%-90%, and the balance is molybdenum and copper.

[0023] The manufacturing process is specifically: using tungsten-molybdenum-copper alloy as the substrate layer, epitaxially growing an AlN buffer layer on the tungsten-molybdenum-copper substrate layer, and then growing an n-type GaN layer, an InGaN / GaN multi-quantum well light-emitting layer, a p-type AlGaN layer, The p-type GaN layer, and then sequentially fabricate the current spreading layer and the P electrode on the surface of the p-type GaN layer; then transfer the epitaxial layer to the con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com