Method for preparing silicon solar cell positive electrode and main grid paste thereof

A technology of silicon solar cells and front electrodes, applied in the direction of conductive materials dispersed in non-conductive inorganic materials, cable/conductor manufacturing, circuits, etc., can solve the problems of waste materials, achieve the degree of inhibition of penetration, excellent mechanical bonding force , the effect of improving conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Example 1: A silicon solar cell positive electrode busbar paste and its preparation method

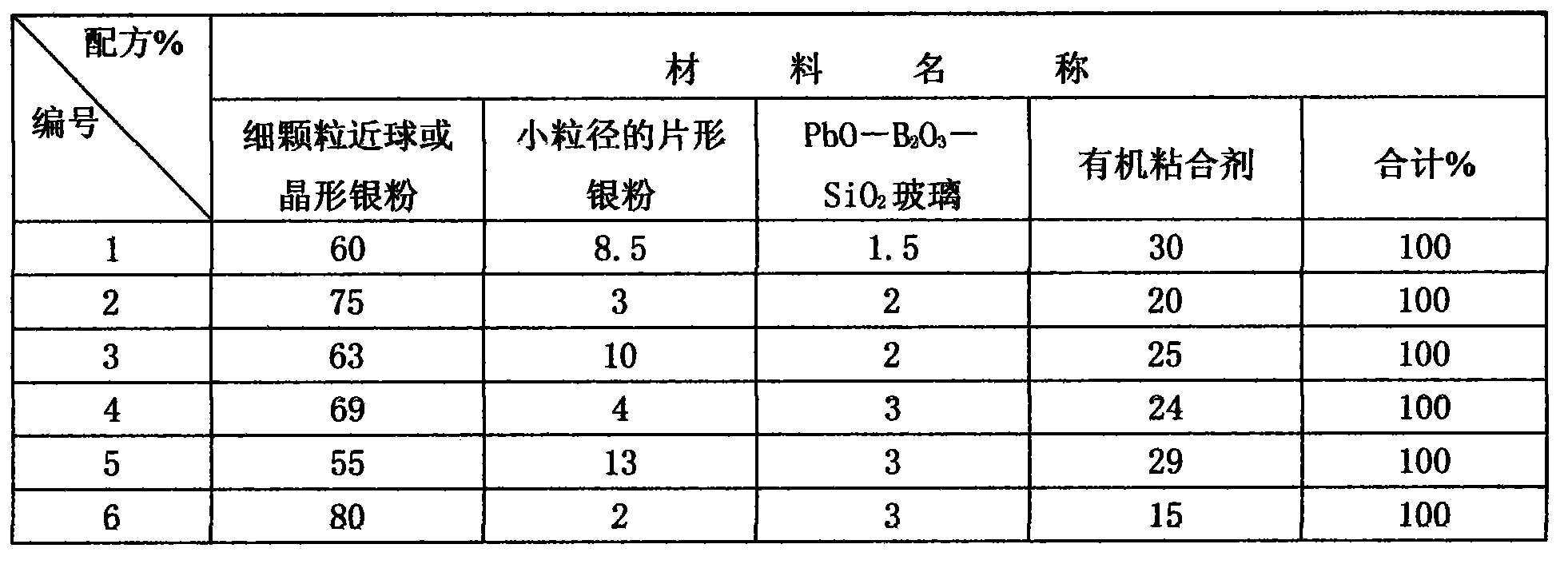

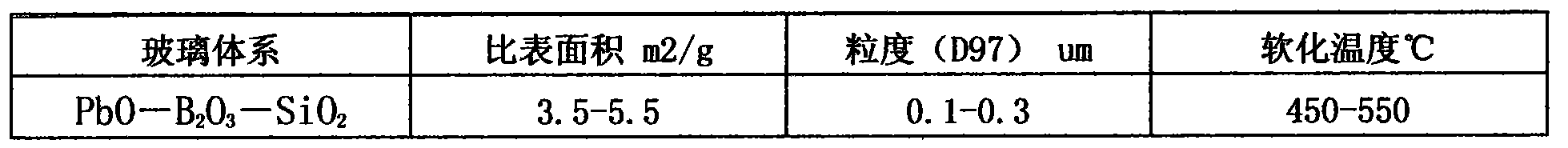

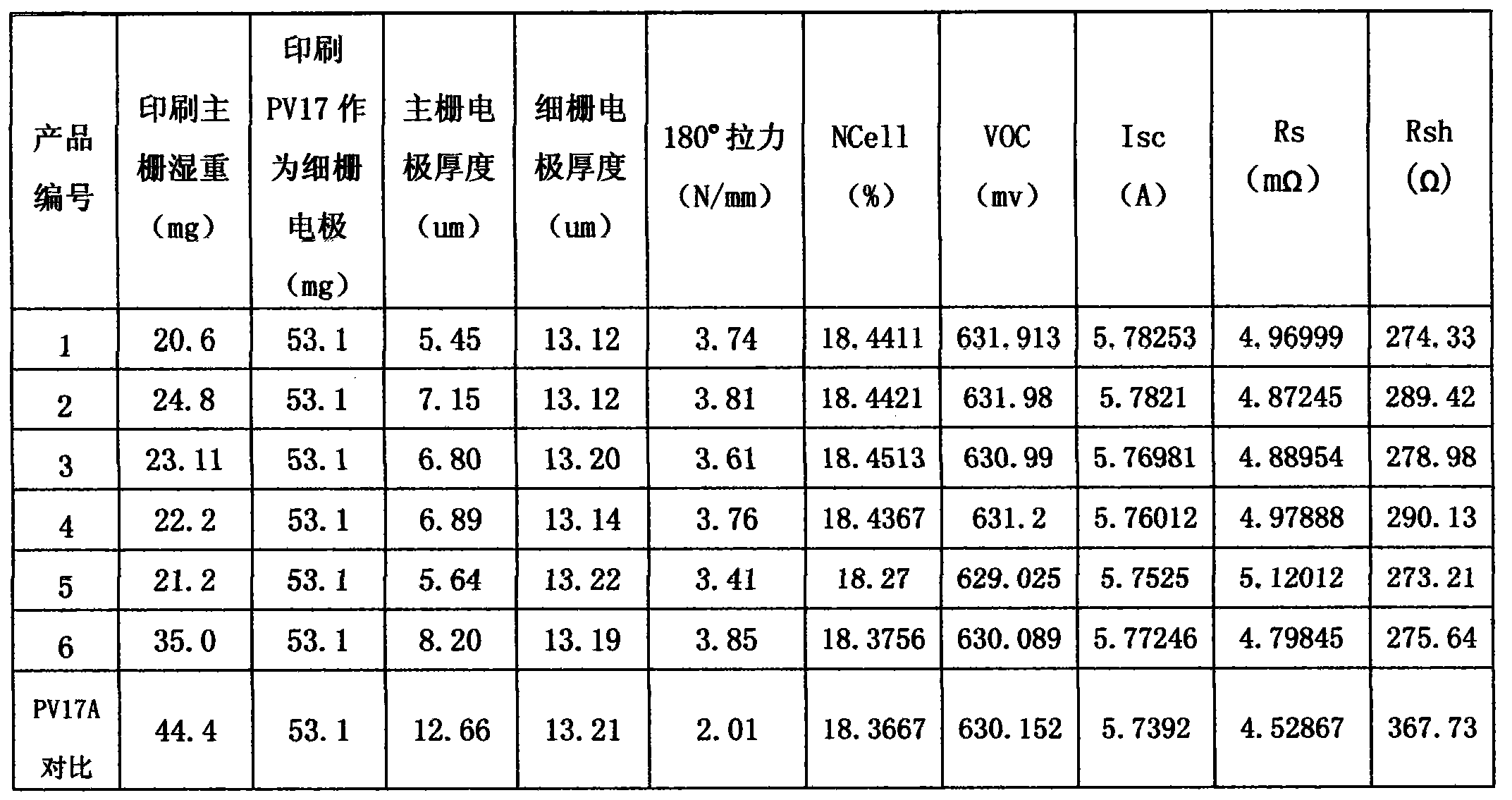

[0050] see image 3 , according to No. 1-6 formulations in Table 1, the main material with good dispersion and uniform composition can be obtained after component adjustment, dispersion, rolling and other processes. The metal conductive powder described in the formula is composed of fine particles of nearly spherical silver powder with a particle size of 0.5-2.5 μm and a tap density of 3.0-4.0 g / ml, and a small particle-sized flake-shaped silver powder with a particle size of 2-5 μm and a tap density of At 2-3.5g / ml, the glass powder is PbO-B 2 o 3 -SiO 2 glass system. One or more of the high molecular resin ethyl cellulose and acrylic resin. The solvent is one or more of terpineol and butyl carbitol ester. The glass formulation selected in the recipe is as figure 2 As shown in 1-6, after mixing the materials evenly, use a three-roll mill to fully grind and roll to reach...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com