Modification method for functionalizing surface of material

A surface functionalization and modification technology, applied in the direction of metal material coating process, can solve the problems of difficult control of process parameters, complicated operation and expensive, and achieve easier control of process parameters, low implementation cost, and strong universality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

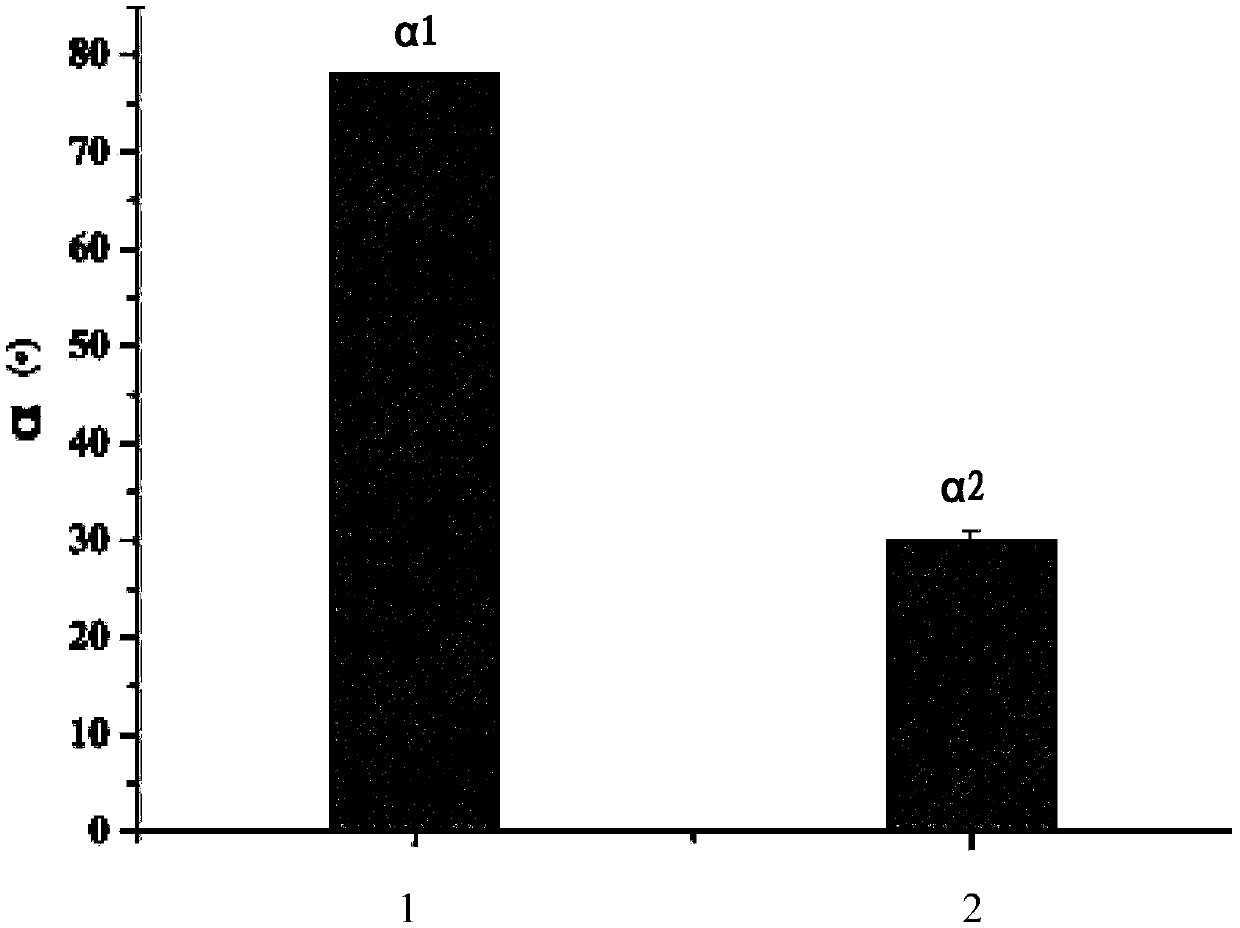

[0041] Example 1: Functional modification of glass slide surface temperature sensitivity

[0042] a), preparation of dopamine functional monomer:

[0043] a10), 3.83g of borax, 1.9g of dopamine hydrochloride, and 100mL of water were placed in a 250mL reaction device, stirred and dissolved, and the pH value was adjusted to 9-10 with aqueous sodium carbonate;

[0044] Slowly drop 1.05 g of methacryloyl chloride into the reaction device, and stir and react for 24 hours at room temperature to obtain a reaction solution;

[0045] a20), using concentrated hydrochloric acid to adjust the reaction solution obtained in the above step a10) to an acidic reaction solution with a pH value of 2, use ethyl acetate to extract and separate the acidic reaction solution, the number of extractions is selected for 3 times, and of course 4 times or More than 4 times, the organic phases obtained by each extraction were combined to obtain the organic phase;

[0046] a30), the organic phase obtained...

Embodiment 2

[0051] Embodiment 2: the functional modification of antibacterial performance on the surface of stainless steel sheet

[0052] a), preparation of dopamine functional monomer:

[0053] a10), 3.83g of borax, 1.9g of dopamine hydrochloride, and 100mL of water were placed in a 250mL reaction device, stirred and dissolved, and the pH value was adjusted to 9-10 with aqueous sodium carbonate;

[0054] Slowly drop 1.05 g of methacryloyl chloride into the reaction device, and stir and react for 24 hours at room temperature to obtain a reaction solution;

[0055] a20), using concentrated hydrochloric acid to adjust the reaction solution obtained in the above step a10) to an acidic reaction solution with a pH value of 2, use ethyl acetate to extract and separate the acidic reaction solution, the number of extractions is selected for 3 times, and of course 4 times or More than 4 times, the organic phases obtained by each extraction were combined to obtain the organic phase;

[0056] a30...

Embodiment 3

[0061] Example 3: Functional Modification of Surface pH Sensitivity of Polyurethane Tubes

[0062] a), preparation of dopamine functional monomer:

[0063] a10), 3.83g of borax, 1.9g of dopamine hydrochloride, and 100mL of water were placed in a 250mL reaction device, stirred and dissolved, and the pH value was adjusted to 9-10 with aqueous sodium carbonate;

[0064] Slowly drop 1.05 g of methacryloyl chloride into the reaction device, and stir and react for 24 hours at room temperature to obtain a reaction solution;

[0065] a20), using concentrated hydrochloric acid to adjust the reaction solution obtained in the above step a10) to an acidic reaction solution with a pH value of 2, use ethyl acetate to extract and separate the acidic reaction solution, the number of extractions is selected for 3 times, and of course 4 times or More than 4 times, the organic phases obtained by each extraction were combined to obtain the organic phase;

[0066] a30), the organic phase obtaine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com