Preparation method of porous polymer microspheres

A porous polymer and microsphere technology, applied in the field of preparation of porous polymer microspheres, can solve the problems that the particle size can only be controlled to a few millimeters, the cost of mold design and manufacturing is high, and it is difficult to form a regular spherical shape. Wide range of size adjustment, increased stability, and good penetration of holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The invention provides a kind of preparation method of porous polymer microsphere, comprises the steps:

[0038] Step 1: Mix the oil-soluble monomer, cross-linking agent and emulsifier to obtain the oil phase. Those skilled in the art know easily that the ratio of oil-soluble monomer, cross-linking agent and emulsifier can be selected according to actual conditions. Preferably, the mass ratio of oil-soluble monomer, cross-linking agent and emulsifier is (3~8): (1~4):(1~3), more preferably, the mass ratio of oil-soluble monomer, crosslinking agent and emulsifier is (9~13):(4~6):(3~5).

[0039] The general formula of the oil-soluble monomer is preferably CH 2 =CR 1 R 2 , where R 1 is hydrogen or methyl, R 2 Is aryl, ester or COOR 3 , R 3 is alkyl or haloalkyl, more preferably styrene, 4-methylstyrene, 4-ethylstyrene, chlorostyrene, chloromethylstyrene, butyl acrylate, butyl methacrylate and 2- At least one of ethylhexyl acrylate and the like.

[0040]The crosslin...

Embodiment 1

[0055] (1) Add 2.25g of styrene, 0.75g of ethylene glycol dimethacrylate and 0.75g of 12-acryloyloxy-9-octadecenoic acid into a 100ml beaker, and use a syringe to take a certain amount of ammonia water to adjust pH to 8, after mixing evenly, a light yellow viscous opaque liquid is obtained, which is the oil phase;

[0056] (2) Add 60.0g of distilled water dropwise to the oil phase under stirring at 300r / min to prepare a double emulsion;

[0057] (3) Transfer the double emulsion to a 100ml wide-mouth bottle, and after 30 minutes of nitrogen gas to remove the oxygen in the system, the sealed container is sent into the cobalt source radiation to initiate polymerization, and the dose rate is kept at 30.2Gy·min -1 , After 48 hours, the product was taken out, sieved, washed twice with distilled water, and then washed with ethanol. After drying, the porous polymer microsphere S1 was obtained, and the yield could reach 70%.

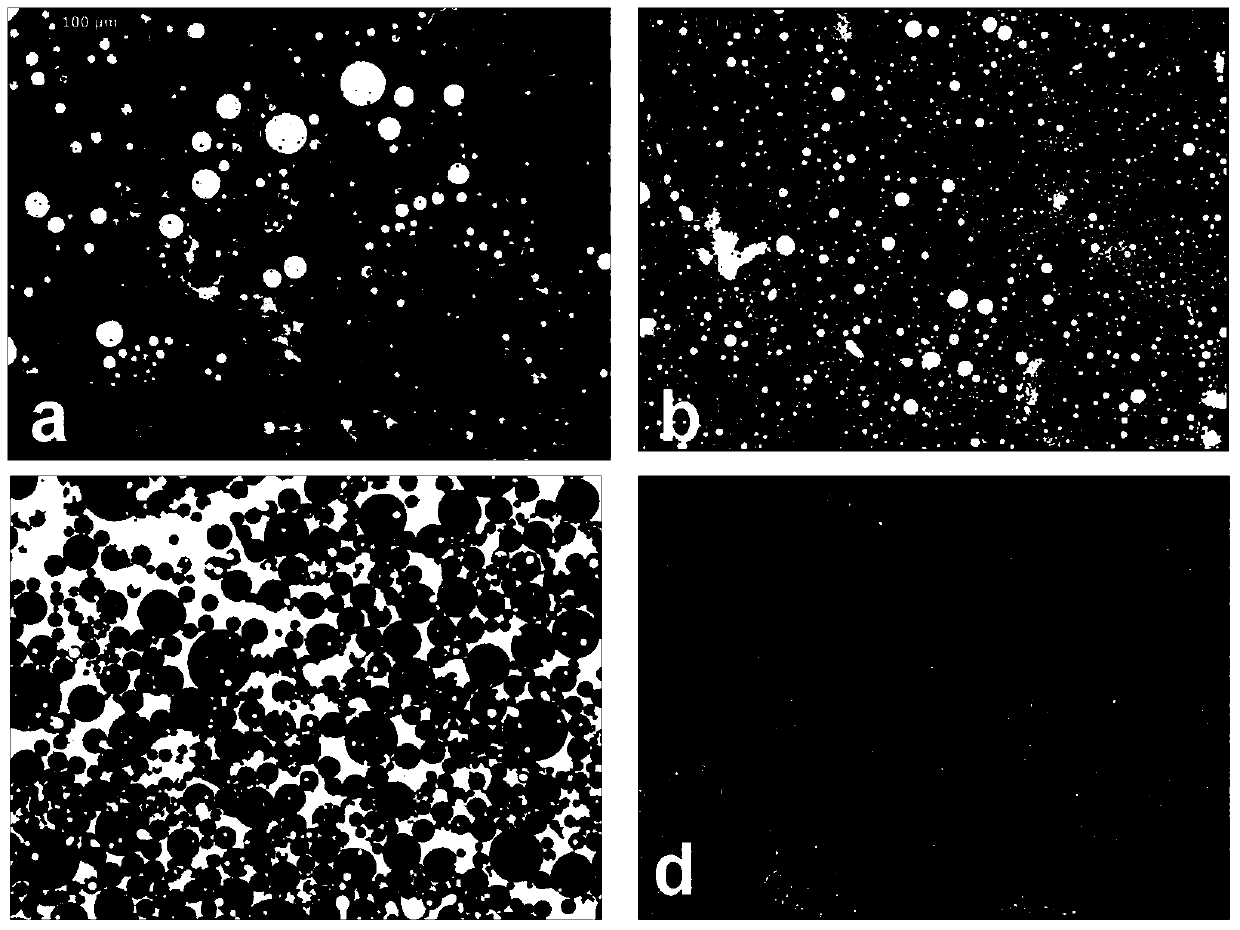

[0058] Such as figure 2 and image 3 As shown, only an ...

Embodiment 2

[0061] Repeat Example 1 with the following difference: replace "ethylene glycol dimethacrylate" with "divinylbenzene".

[0062] Finally, porous polymer microspheres S2 were obtained with a yield of up to 70%.

[0063] Such as Figure 5 As shown, the surface and internal pores of S2 are closed, the average size of the microspheres is 52 μm, and the specific surface area is 13.6 m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Average size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com