Finish machining method of direct lathe machining of optical collecting mirror in EUV (extreme ultra-violet) lithography light sources

A technology of extreme ultraviolet lithography and collecting mirrors, which is applied in the direction of turning equipment, turning equipment, metal processing equipment, etc., to achieve the effects of high processing precision, short cycle time and saving processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

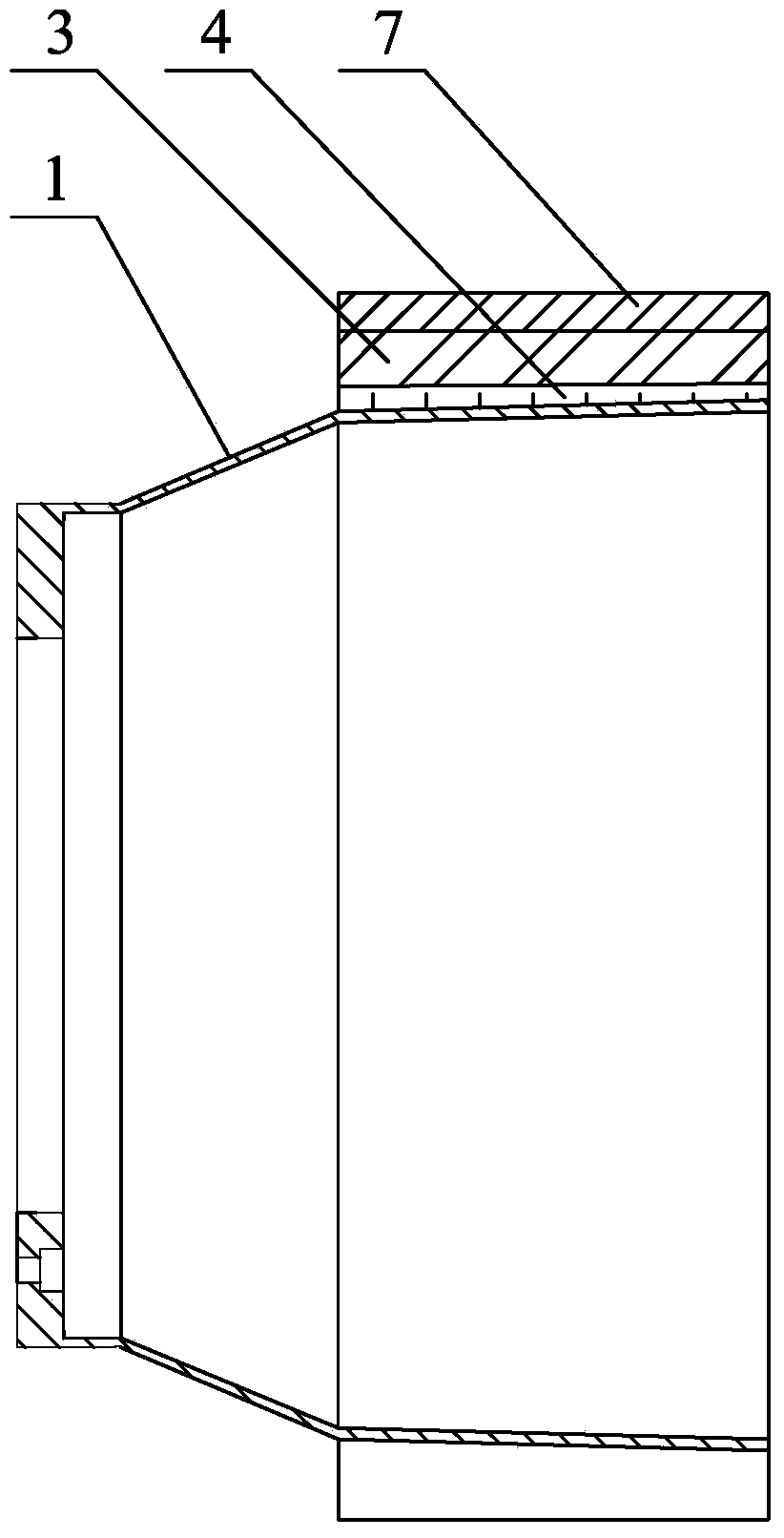

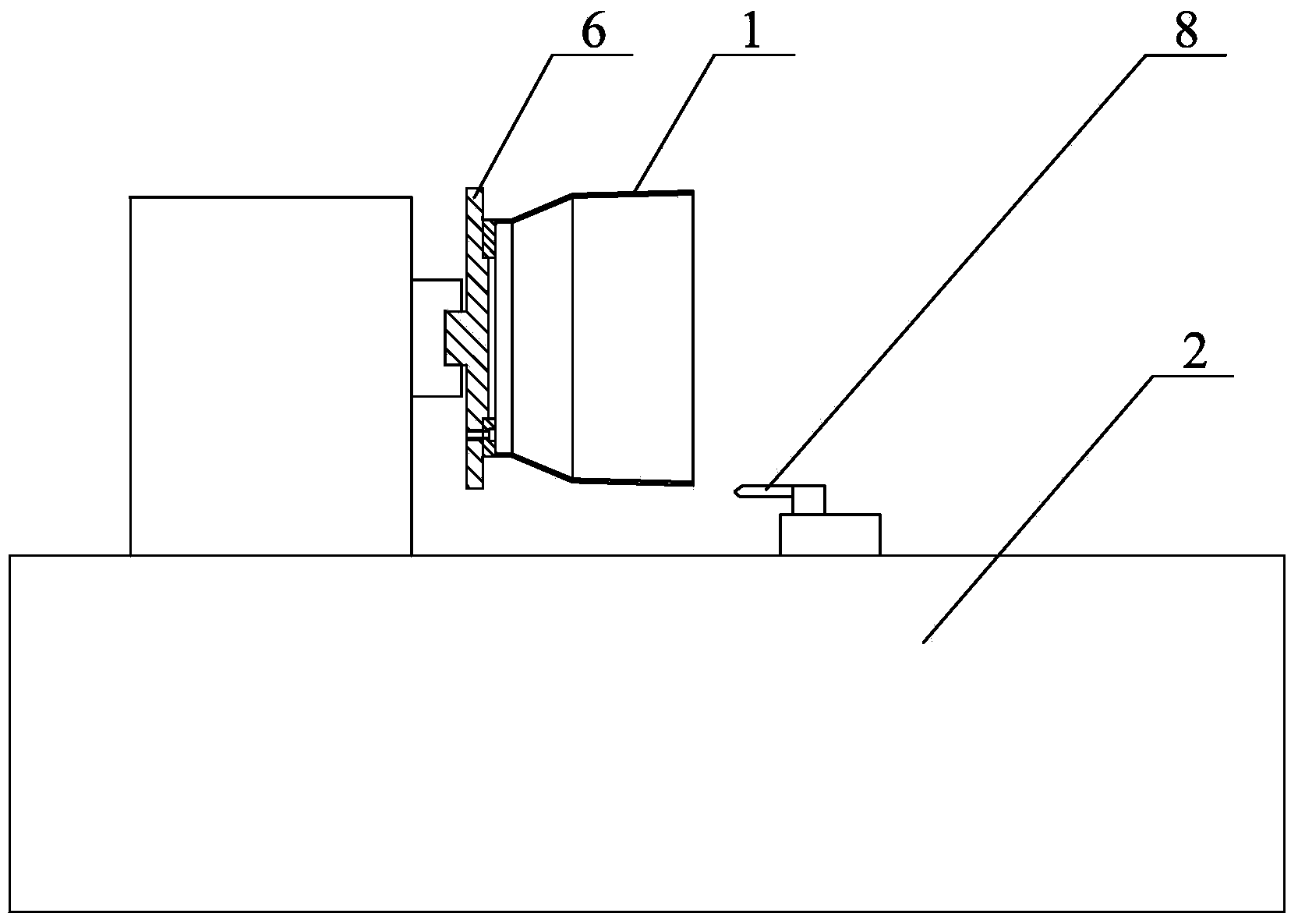

[0020] Specific implementation mode one: combine figure 2 with image 3 To illustrate, the direct turning and finishing method of the optical collecting mirror in the extreme ultraviolet lithography light source of the present embodiment, the method includes the following steps:

[0021] The first step: install the collection lens tube blank 1; firstly install the collection lens tube blank 1 after rough turning, the surface shape of the collection lens tube blank 1 is composed of hyperboloid and ellipsoidal surface (the collection lens tube blank 1 The surface shape is the inner surface of the collecting lens barrel blank 1), and the collecting lens barrel blank 1 (inner surface) is corrected to ensure that the runout value is within the range of 0.1mm to 0.5mm;

[0022] Step 2: Rough turning in finishing turning; use the finishing lathe to carry out rough turning in finishing turning on the collection lens tube blank 1, each feed is 0.04-0.06mm, and the number of times of ...

specific Embodiment approach 2

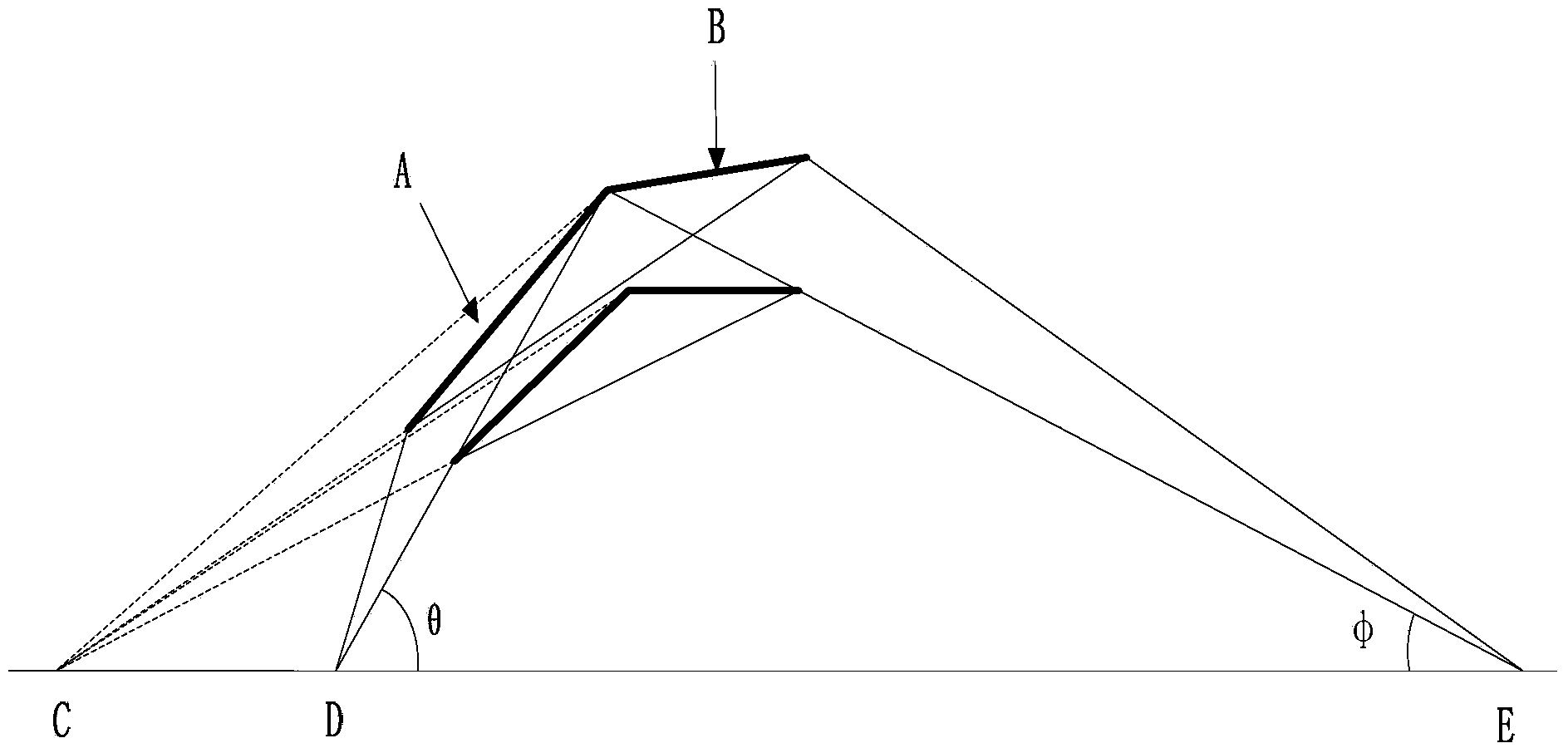

[0028] Specific implementation mode two: combination figure 1 Illustrate that the rough turning process of the collecting lens barrel blank 1 in the first step of the present embodiment is realized in the following way: firstly, the aluminum alloy blank is rough turned into a cylindrical workpiece with a common numerically controlled lathe, and the wall thickness of the cylindrical workpiece is 6.5 mm. , and then turned by an ordinary CNC lathe according to the collection mirror type and leave the margin required for the finish car, the margin is 0.5 ~ 1mm, and then undergo 7-8 dimensional stabilization treatments (to ensure the dimensional stability of the aluminum alloy material and meet the requirements of the collection process). mirror application requirements) and then made into a collecting mirror tube blank 1. The undisclosed technical features in this embodiment are the same as those in the first embodiment.

specific Embodiment approach 3

[0029] Specific implementation mode three: combination figure 2 Explain that in the fourth step of the present embodiment, before the finish car, the outer surface of the collecting lens barrel blank 1 completed in the third step is covered with a nylon sleeve 3, and the nylon sleeve 3 is covered by vacuum cement 4. Sticking on the outer surface of the collecting lens barrel blank 1 can ensure the processing in a rigid state. Strictly control the counterweight (through slow rotation, measure the rotational speed and eccentricity changes during rotation, and the center of the counterweight is located at the axis of the entire lens). The undisclosed technical features in this embodiment are the same as those in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com