Negative-pressure hot smoke de-oiling device

A negative pressure and hot smoke technology, which is applied in the field of mechanical processing and manufacturing, can solve the problems of inapplicable removal of grease from porous mechanical parts, etc., and achieve the effects of shortening the degreasing operation cycle, good degreasing effect, and flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

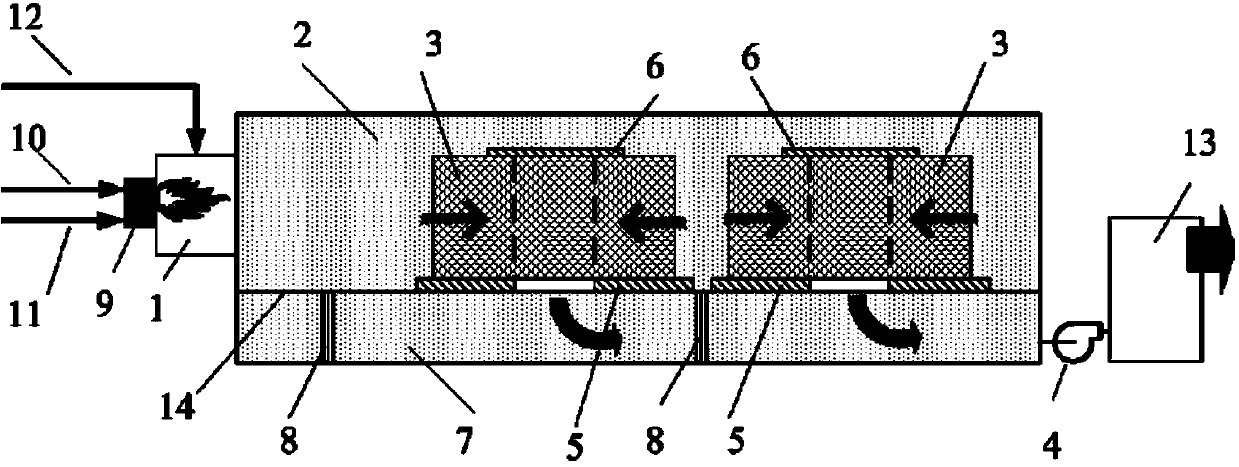

[0036] Such as figure 1The hot smoke negative pressure degreasing device shown includes a hot smoke inlet pipe 1, a high temperature gas chamber 2, a smoke exhaust fan 4, a bottom sealing pressing piece 5, a top sealing pressing piece 6, a negative pressure chamber 7, a supporting column 8, Hot smoke generating device 9, fuel pipeline 10, combustion air pipeline 11, mixed air pipeline 12, exhaust gas treatment device 13, partition 14; porous oily part 3 is placed in high temperature gas chamber 2, and hot smoke inlet pipeline 1 is connected to The high-temperature gas chamber 2 and the hot flue gas generating device 4 are located at the tail of the hot flue gas inlet pipe 1, and its tail is connected with a fuel pipe 10 and a combustion air pipe 11 to generate hot flue gas. The inside of the hot flue gas inlet pipe 1 is provided with Thermocouple and oxygen content measurement device, the measurement results can be used as the basis for adjusting the flue gas temperature and o...

Embodiment 2

[0038] On the basis of Embodiment 1, no less than 3 smoke passage holes are provided on the partition plate 14, and no less than 3 porous oily parts 3 can be treated at the same time for degreasing treatment. Improve work efficiency and save operating costs. When the number of openings on the separator 14 is more than that of the porous oil-carrying parts 3 to be processed, the top sealing sheet 6 can be used to directly seal the smoke holes to prevent short circuit of the smoke. The operational flexibility of the system is improved.

Embodiment 3

[0040] On the basis of Embodiment 1, a heat conduction device is arranged on the exhaust gas treatment device 13, and the heat generated by high-temperature combustion of exhaust gas can be used for industrial heating, domestic heating, etc., so as to achieve the purpose of fully utilizing energy. Heat can also be conducted into the high-temperature gas chamber 2 to increase the temperature in the high-temperature gas chamber 2 . It is also possible to introduce heat into the combustion air duct 11 to preheat the air. Both of these structures can speed up the processing speed, improve the processing efficiency, save costs, reduce heat loss, and better protect the environment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com