Preparation method of zirconium diboride and silicon carbide high-temperature antioxidant coating

A high-temperature anti-oxidation and zirconium diboride technology, which is applied in the coating, metal material coating process, fusion spraying, etc., can solve the problems of low bonding strength, poor oxidation resistance of the coating, and high porosity of the coating. Achieve the effects of reducing porosity, improving coating bonding strength, and avoiding oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

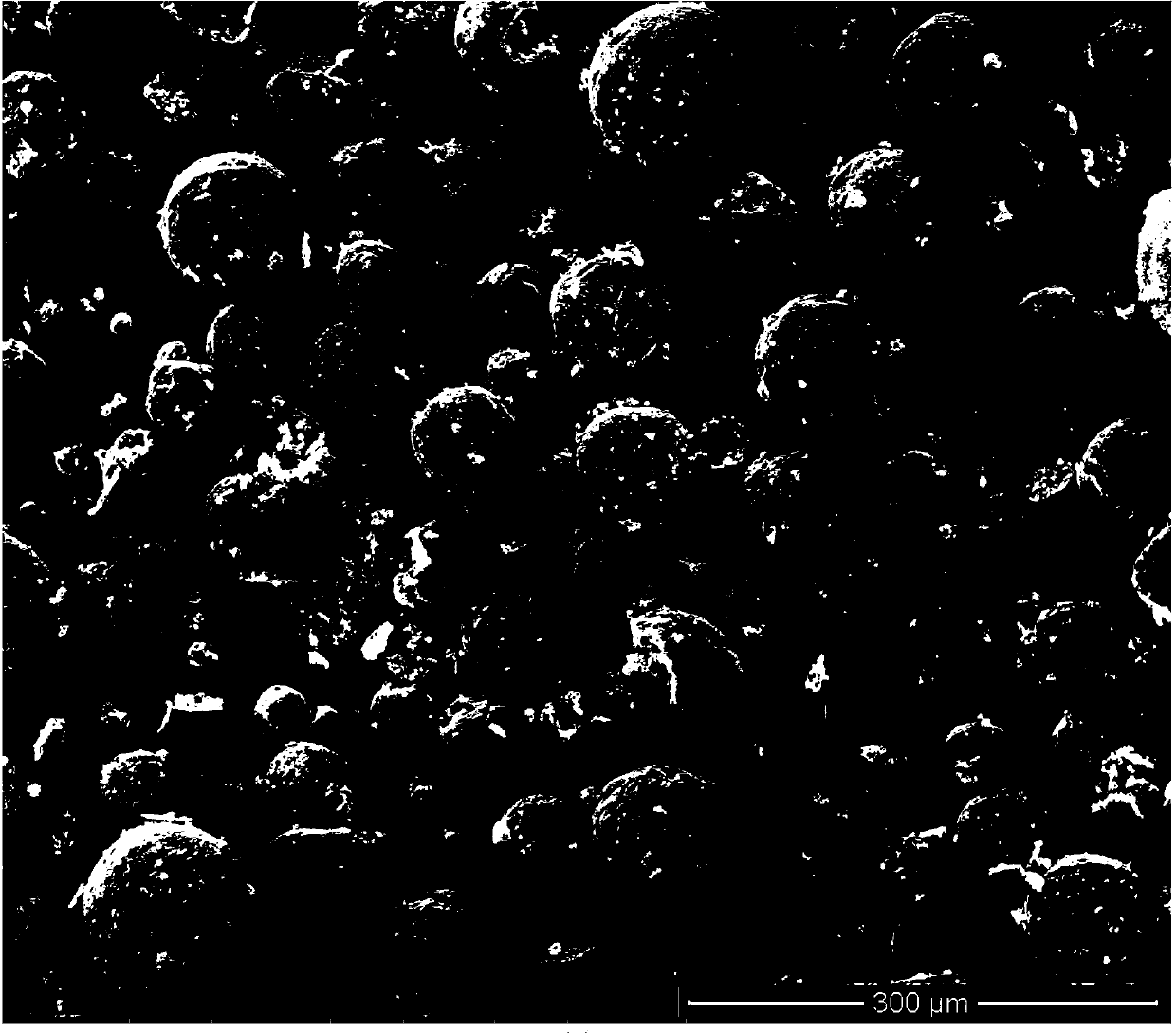

Image

Examples

Embodiment 1

[0027] ZrB of this embodiment 2 -SiC composite powder is composed of the following components in mass percentage: ZrB 2 75%, SiC25%.

[0028] 1) Ingredients ball milling: ZrB with a particle size of 5-15 μm 2 Powder and 0.5-1μm SiC powder are mixed at a mass ratio of 75:25, and then the mixed powder and binder (polystyrene, carboxymethyl cellulose, and polyvinyl alcohol at a mass ratio of 35:35:30) are mixed at a ratio of 90 : mix with a mass ratio of 10, add distilled water of 2 times the weight of the mixture, and prepare a slurry for ball milling for 20 hours;

[0029] 2) Spray drying: Add the slurry obtained in step 1) to a dispersant with a mass ratio of 1% (glycerol, isobutanol, and tributyl phosphate in a mass ratio of 20:35:45), and dry in the spray drying tower Internal atomization drying, the outlet temperature of the drying tower is controlled within the range of 150°C to make granulated powder;

[0030] 3) Sintering and densification: put the granulated powder ...

Embodiment 2

[0036] ZrB of this embodiment 2 -The mass percentage of SiC-coated composite powder is changed to: ZrB 2 70%, SiC30%.

[0037] 1) Ingredients ball milling: ZrB with a particle size of 5-15 μm 2 Powder and 0.5-1μm SiC powder are mixed at a mass ratio of 70:30, and then the mixed powder and binder (polystyrene, carboxymethyl cellulose, and polyvinyl alcohol at a mass ratio of 40:30:30) are mixed at a ratio of 95 : Mix at a mass ratio of 5, add distilled water of 1.5 times the weight of the mixture, and prepare a slurry for ball milling for 25 hours;

[0038] 2) Spray drying: Add the slurry obtained in step 1) to a dispersant with a mass ratio of 1% (glycerol, isobutanol, and tributyl phosphate in a mass ratio of 25:35:40), and dry in the spray drying tower Internal atomization drying, the outlet temperature of the drying tower is controlled within the range of 200°C to make granulated powder;

[0039] 3) Sintering and densification: put the powder obtained in step 2) into a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bond strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com