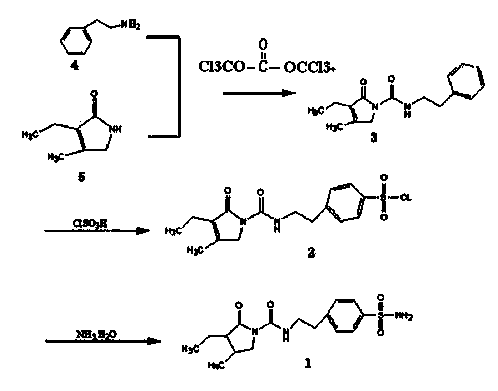

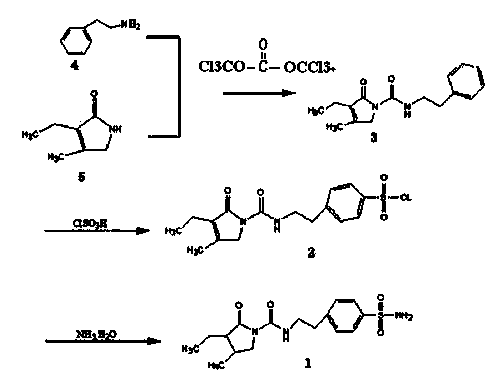

Triphosgene method for synthesizing benzene sulphanilamide, intermediate of glimepiride, drug for Type ii Diabetes Mellitus

A diabetes drug, glimepiride technology, applied in the field of compound preparation, can solve the problems of inconvenient operation and complicated process steps, and achieve the effect of high product yield and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Add 1200 milliliters of dichloromethane, 170 grams of phenethylamine, 175 grams of 3-ethyl-4-methylpyrrolidinone in a 3000 milliliter three-necked flask, and add 132 grams of triphosgene and The mixed solution of 600 ml of dichloromethane, about 3 hours after the end of the dropwise addition, continued to react for 3 hours after the end of the dropwise addition, then warmed up to room temperature, stirred for 2 hours until the end of the reaction, added 800

[0013] Stir in milliliters of water, concentrate to remove the solvent dichloromethane, then add 1000 milliliters of water, stir and cool to 0 ° C, and stir at this temperature for 3 hours, filter, wash with 100 milliliters of ethanol, and dry to obtain 190 grams of intermediate N-[2 -(3-Ethyl-4-methyl-2-oxide-3-pyrroline-1-carboxamido)ethyl]-benzene.

[0014] Pump 640 grams of chlorosulfonic acid into a 2000 ml reactor, and then add 190 grams of N-[2-(3 -Ethyl-4-methyl-2-oxidation-3-pyrroline-1-carboxamido)...

Embodiment 2

[0016] Add 1200 milliliters of methylene chloride, 170 grams of phenethylamine, and 175 grams of 3-ethyl-4-methylpyrrolidone in a 2000 milliliter three-necked flask, and add 152 grams of triphosgene and The mixed solution of 800 ml of dichloromethane, the dropwise addition is completed in about 3 hours, continue to react for 3 hours after the dropwise addition, then warm up to room temperature, stir for 2 hours to the end of the reaction, add 800 ml of water and stir, concentrate and remove the solvent dichloromethane , then add 1000 ml of water, stir and cool to 0°C, and stir at this temperature for 3 hours, filter, wash with 100 ml of ethanol, and dry to obtain 193 g of intermediate 3.

[0017] Pump 640 grams of chlorosulfonic acid into a 2000 milliliter reactor, and then add 193 grams of N-[2-(3 -Ethyl-4-methyl-2-oxidation-3-pyrroline-1-carboxamido)ethyl]-benzene Stir for 15 minutes after adding the materials, slowly raise the temperature to room temperature, and keep the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com