Power semiconductor module assembled through three-dimensional structural units

A power semiconductor, three-dimensional structure technology, applied in the direction of semiconductor devices, semiconductor/solid-state device components, electrical components, etc., can solve the problems of reducing the service life of modules, stripping of bonding wires, uneven cooling channel structure, etc., to enhance heat dissipation capacity, increased power density, and improved thermal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

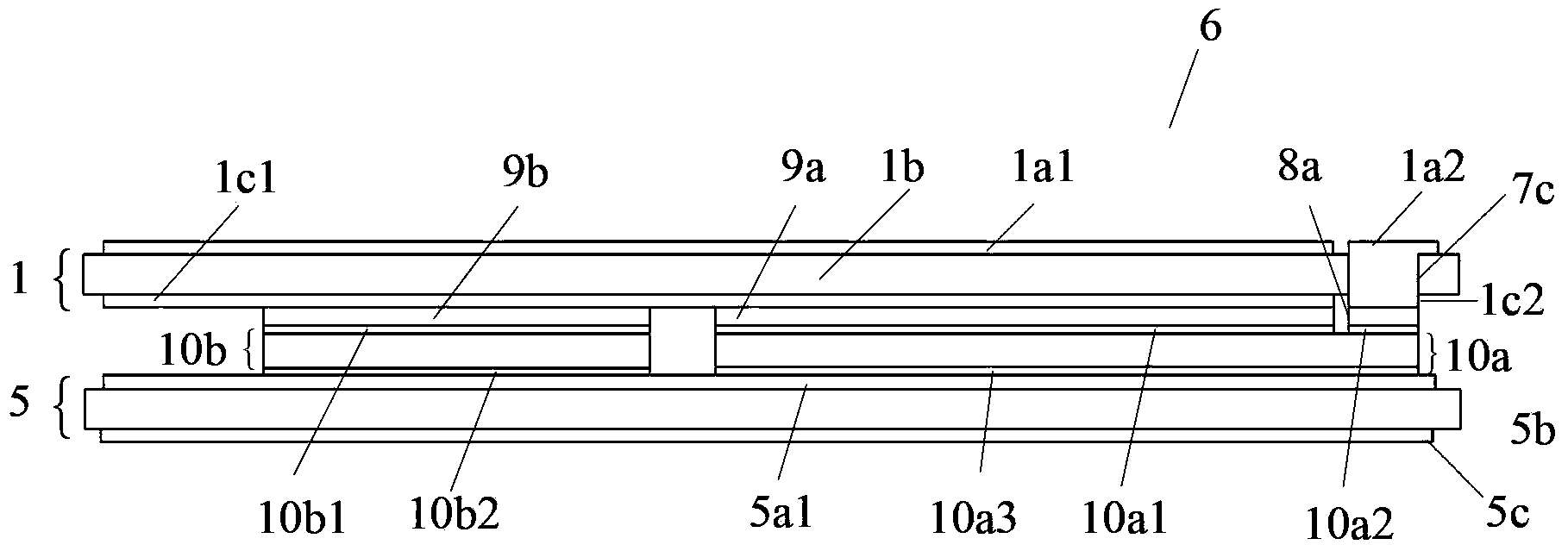

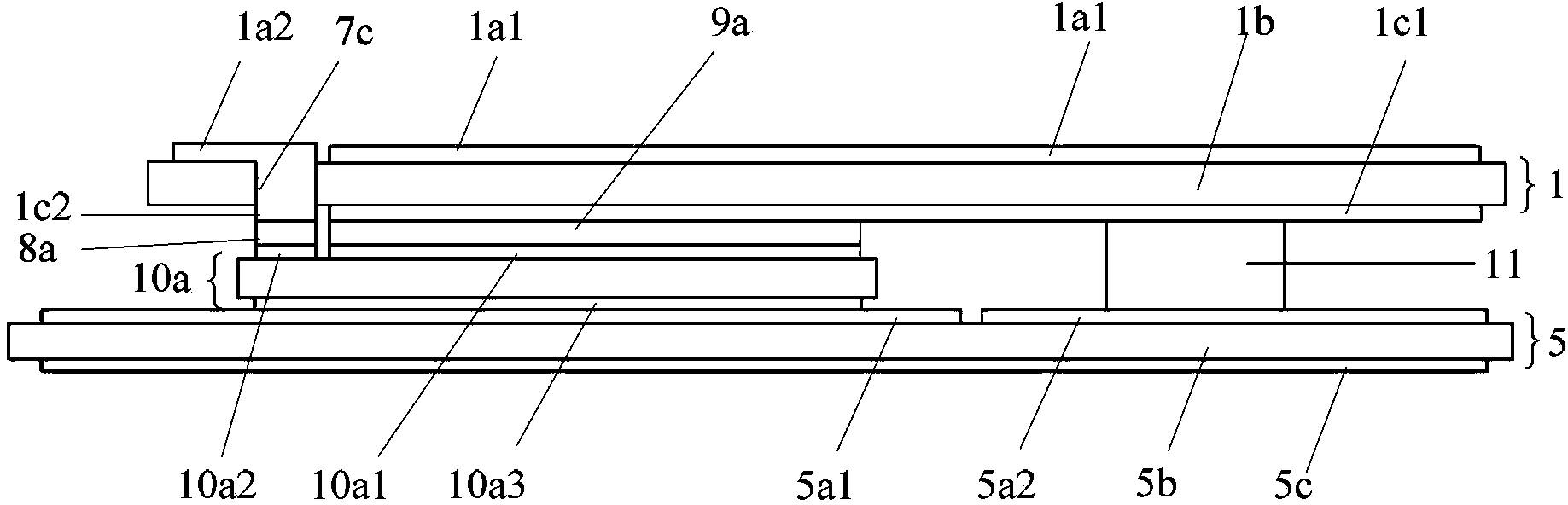

[0027] The power semiconductor module of the present invention is composed of multiple three-dimensional structural units, and each three-dimensional structural unit is fixedly installed on the insulating base plate. The emitter of one three-dimensional structure unit is connected in series with the collector of another three-dimensional structure unit through the connection terminal to form a half-bridge unit, and multiple half-bridge units are connected in parallel.

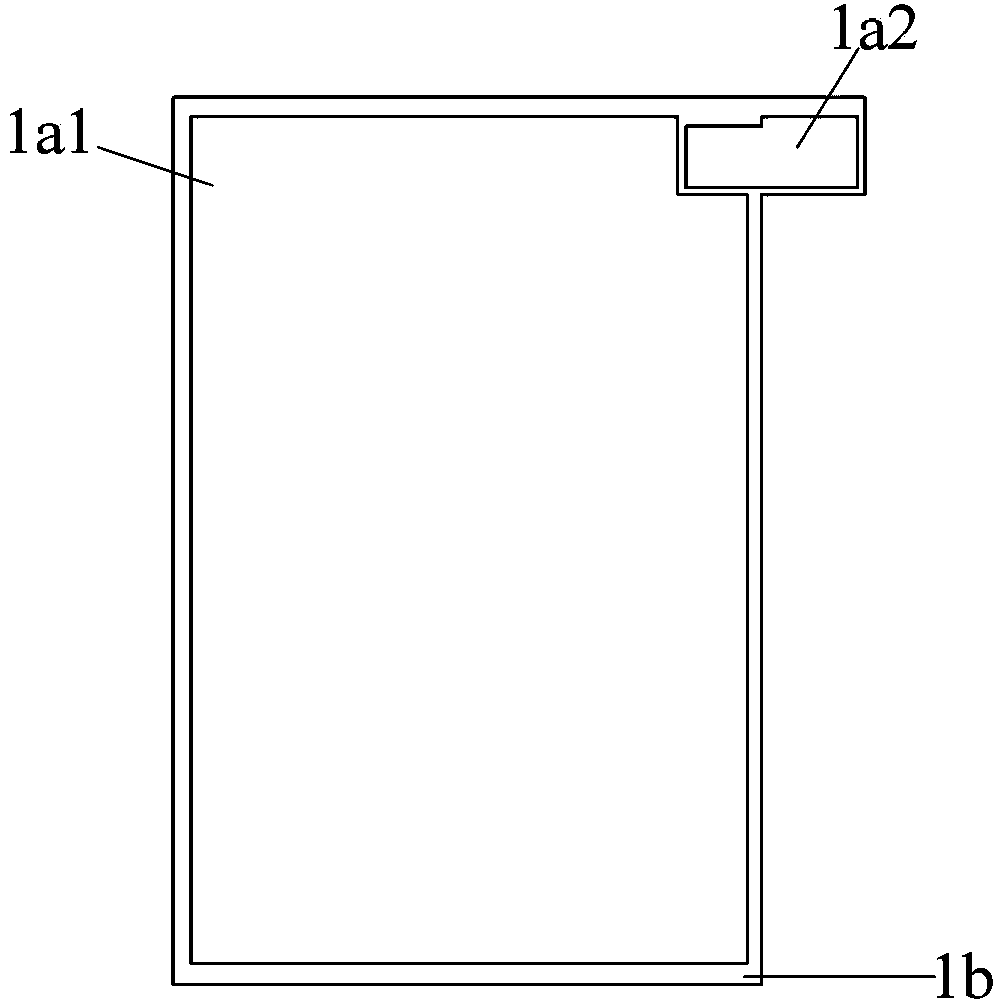

[0028] Such as Figure 1a As shown, the three-dimensional structure unit 6 includes a fully controlled power semiconductor chip 10a, an uncontrolled power semiconductor chip 10b, a first substrate 1, a second substrate 5, a first metal pad 8a, and a second metal pad 9a, And the third metal gasket 9b. The fully controlled power semiconductor chip 10a and the uncontrolled power s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com