Exposure apparatus and exposure method

An exposure device and technology to be exposed, applied in the field of substrate manufacturing, can solve the problems of surface morphology developer damage, reduced product performance indicators, loose pattern structure, etc. The effect of structural stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

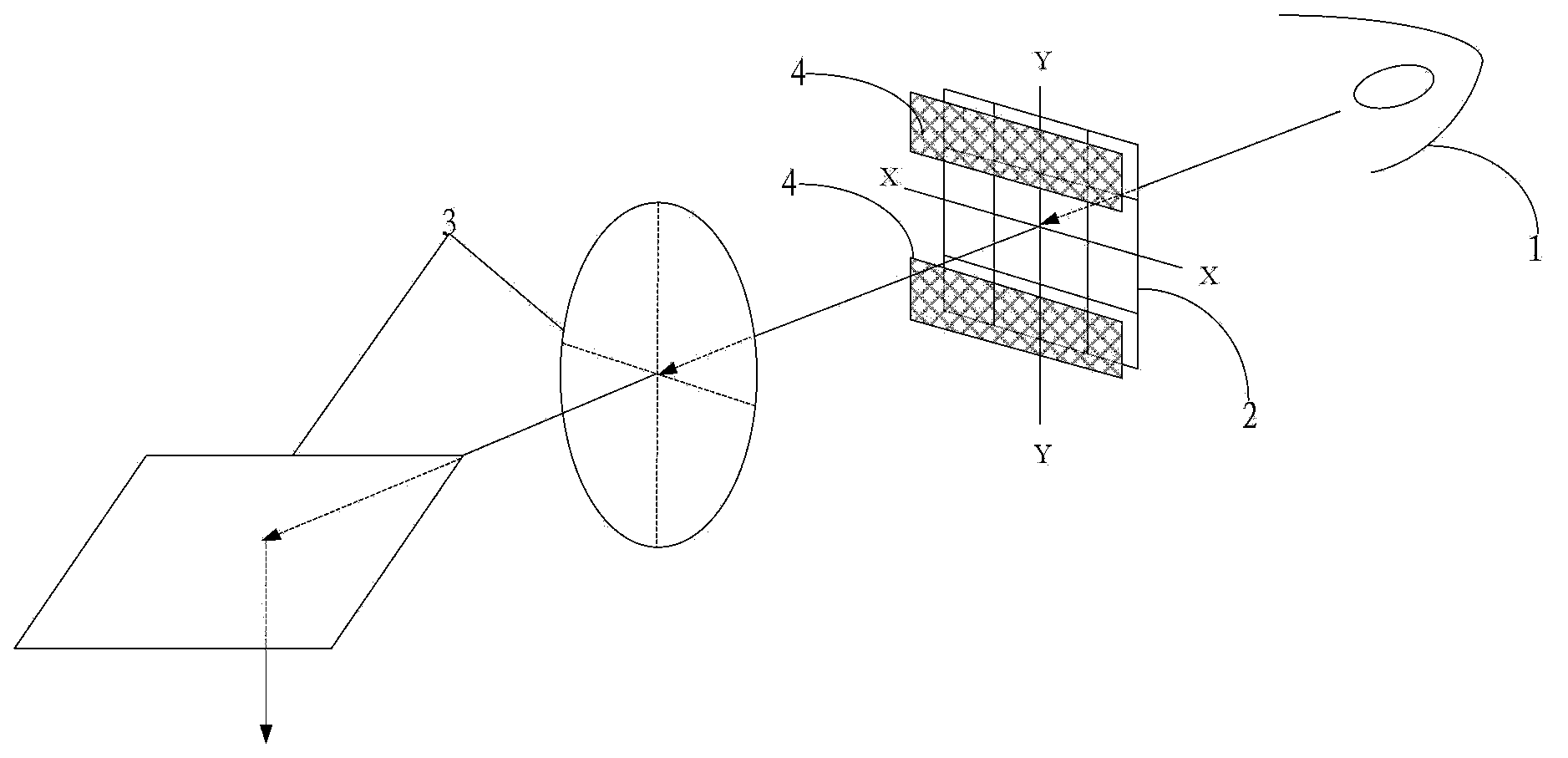

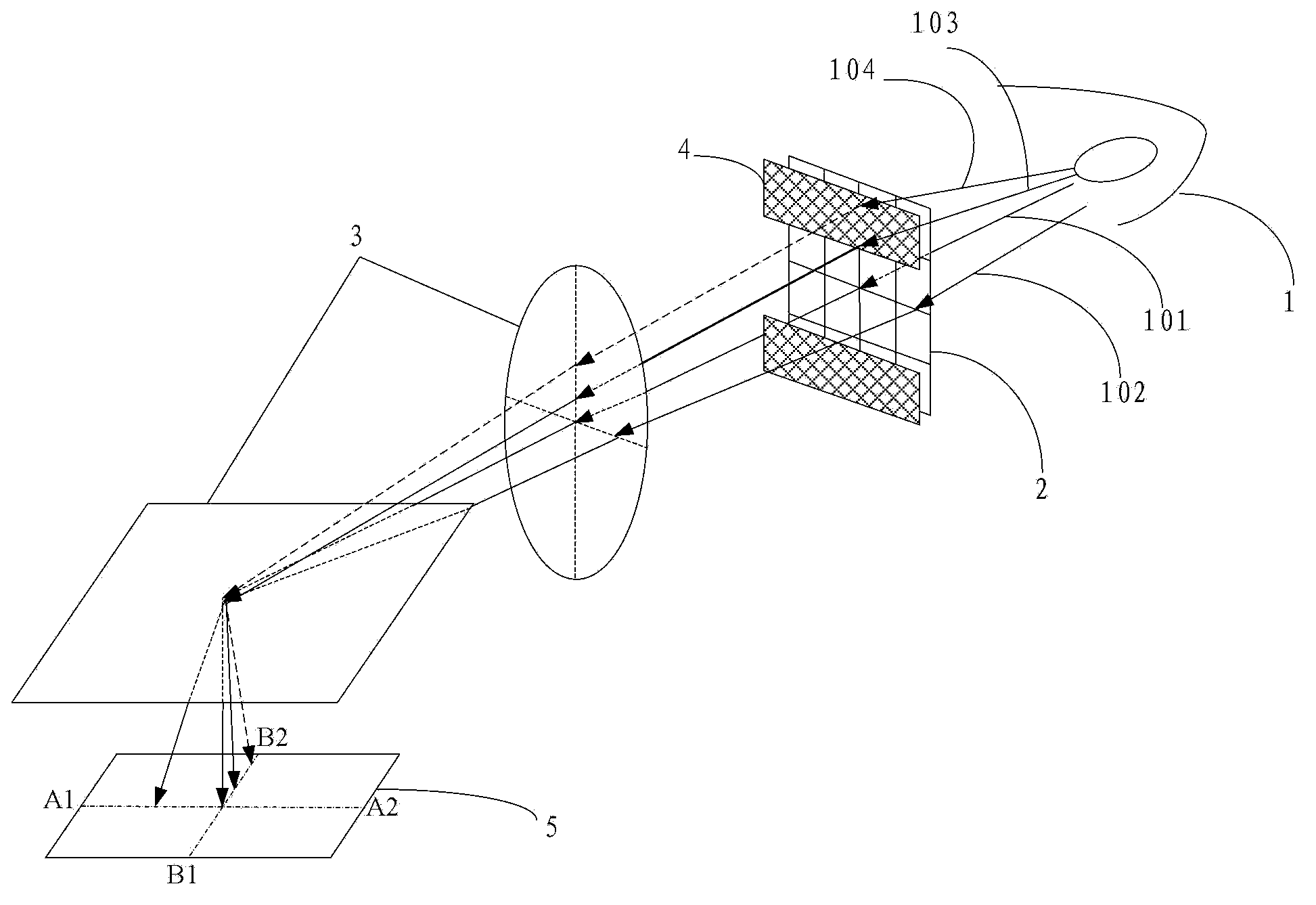

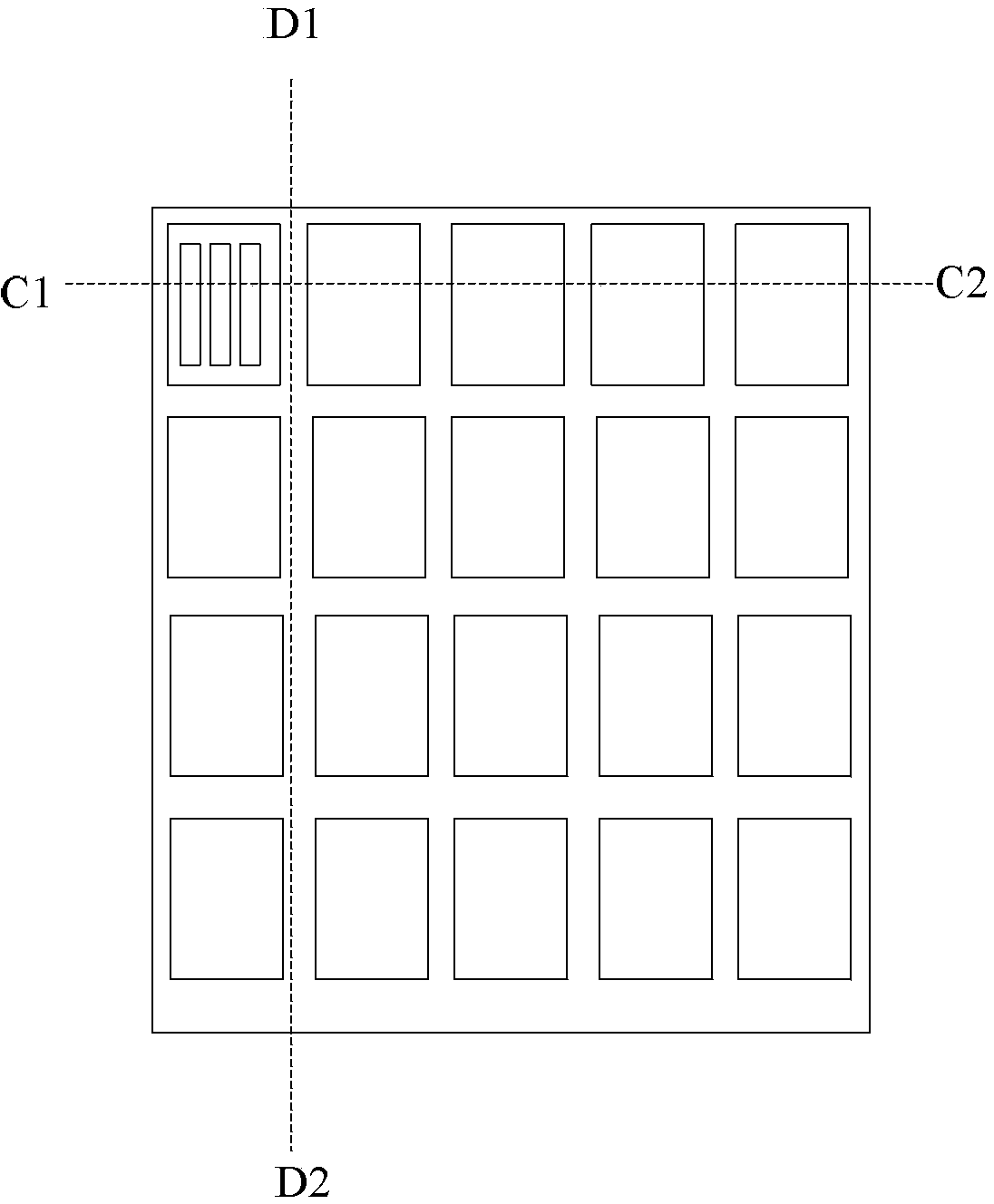

[0031] An embodiment of the present invention provides an exposure device, such as figure 1 As shown, the exposure device includes: an exposure light source 1, a compound eye system 2, an optical system 3, and two diaphragms 4, and the two diaphragms 4 are arranged on the incident surface side or the exit surface of the compound eye system 2 One side, and the two diaphragms 4 are arranged symmetrically with respect to the center of the compound eye system 2; wherein, the orientation of the opening formed by the two diaphragms 4 (hereinafter referred to as the opening orientation) depends on the key of the component to be exposed Size orientation adjustment.

[0032] H...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com