A method for surface alloy modification of nanoporous gold

A nanoporous gold and nanotechnology, applied in the field of electrochemistry, can solve the problems of limited, difficult to uniformly modify the inner surface, high toxicity, etc., and achieve good conductivity and stability, high corrosion resistance, and high toxicity resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] A method for alloying and modifying nanoporous gold. The pulse potential method is used to deposit alloy materials on the surface of nanoporous gold. The steps are as follows:

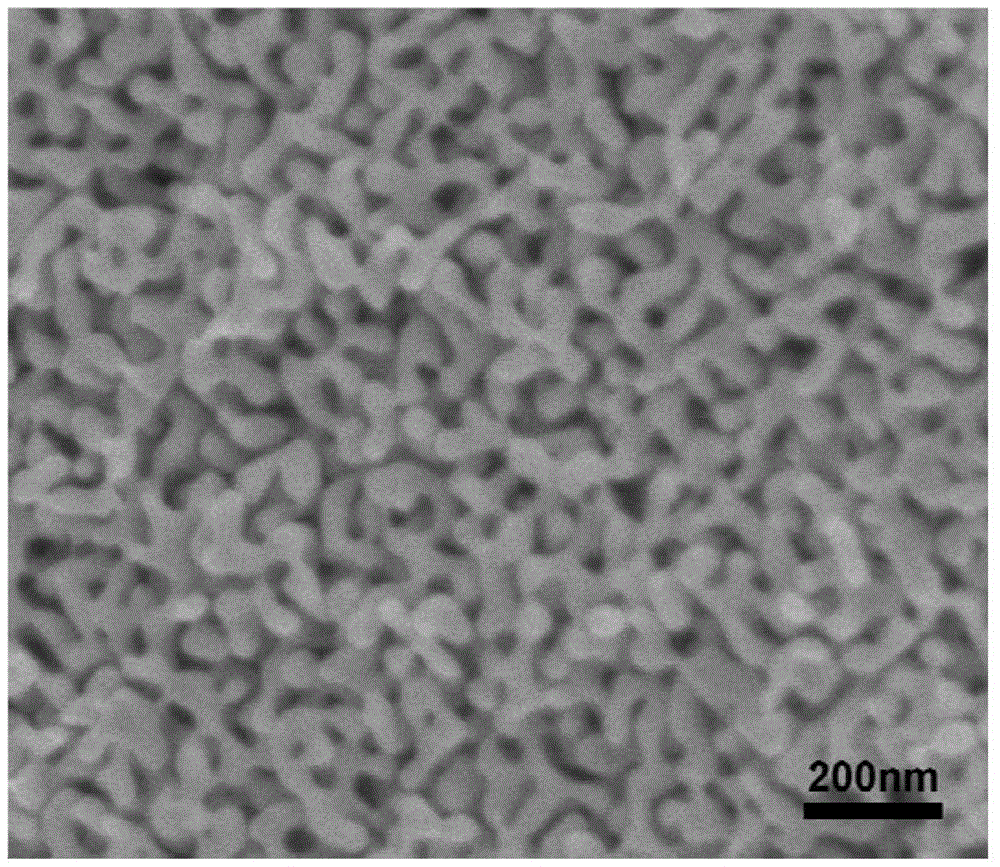

[0054] Connect nanoporous gold with a thickness of 100nm, a width of 1cm, a length of 1.2cm, and a pore wall size of 30nm to the electrode, and place it at 0.02mmol / LBi 3+ and 2mmol / LPt 4+ In the mixed solution, apply a pulse potential, the low potential is constant at -0.5V (relative to the mercury mercurous sulfate electrode), each 2s, the high position is constant at 0V (relative to the mercury mercurous sulfate electrode), each time 20s, two A potential constitutes a pulse cycle, and the nanoporous gold-supported platinum-bismuth alloy catalyst is prepared through 12 cycles.

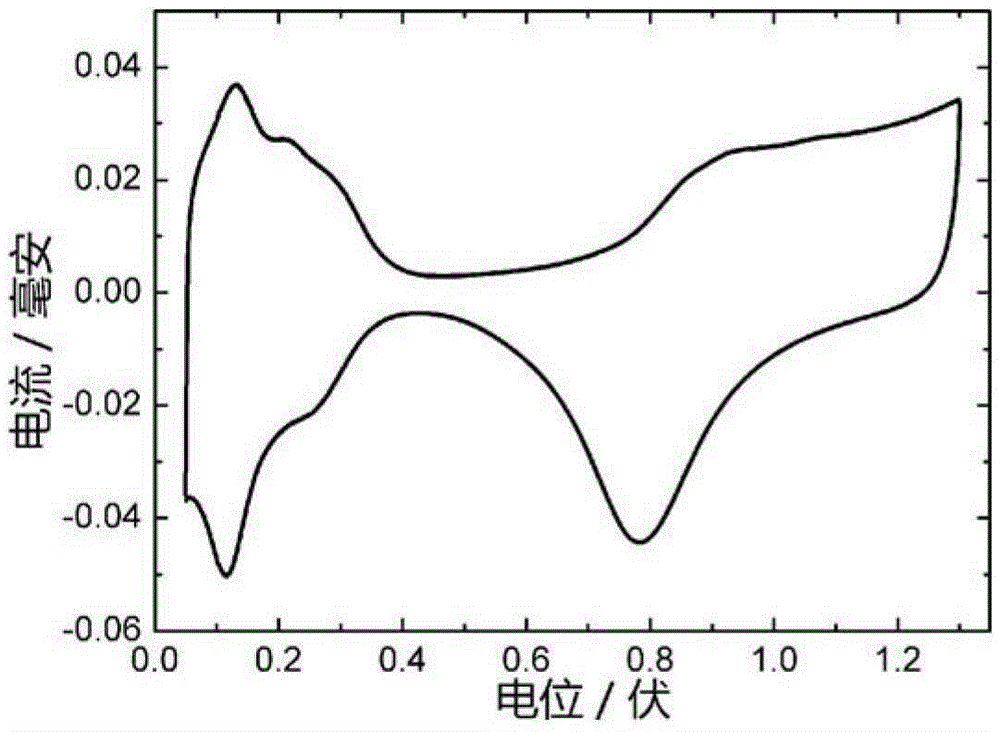

[0055] The nanoporous gold-supported platinum-bismuth alloy catalyst sample prepared above was dissolved in 0.1mol / L HClO 4 The cyclic voltammetry performance was tested in the solution, and the cyclic voltammetry cu...

Embodiment 2

[0058] A method for alloying and modifying nanoporous gold. The pulse potential method is used to deposit alloy materials on the surface of nanoporous gold. The steps are as follows:

[0059] Connect nanoporous gold with a thickness of 100nm, a width of 1cm, a length of 1.2cm, and a pore wall size of 30nm to the electrode, and place it at 0.06mmol / LBi 3+ and 2mmol / LPt 4+ In the mixed solution, apply a pulse potential, the low potential is constant at -0.5V (relative to the mercury mercurous sulfate electrode), each 2s, the high position is constant at 0V (relative to the mercury mercurous sulfate electrode), each time 20s, two A potential constitutes a pulse cycle, and the nanoporous gold-supported platinum-bismuth alloy catalyst is prepared through 12 cycles.

[0060] The nanoporous gold-supported platinum-bismuth alloy catalyst sample prepared above was dissolved in 0.1mol / L HClO 4 The cyclic voltammetry performance was tested in the solution, and the cyclic voltammetry cu...

Embodiment 3

[0066] A method for alloying and modifying nanoporous gold. The pulse potential method is used to deposit alloy materials on the surface of nanoporous gold. The steps are as follows:

[0067] Connect nanoporous gold with a thickness of 100nm, a width of 1cm, a length of 1.2cm, and a pore wall size of 30nm to the electrode, and place it at 0.1mmol / LRu 3+ and 2mmol / LPt 4+ In the mixed solution, the low potential is constant at -0.5V (relative to the mercury mercurous sulfate electrode), 2s each time, and the high position is constant at 0V (relative to the mercury mercurous sulfate electrode), 20s each time, the two potentials constitute a Pulse cycle, 24 cycles to prepare a nanoporous gold-supported platinum-ruthenium alloy catalyst.

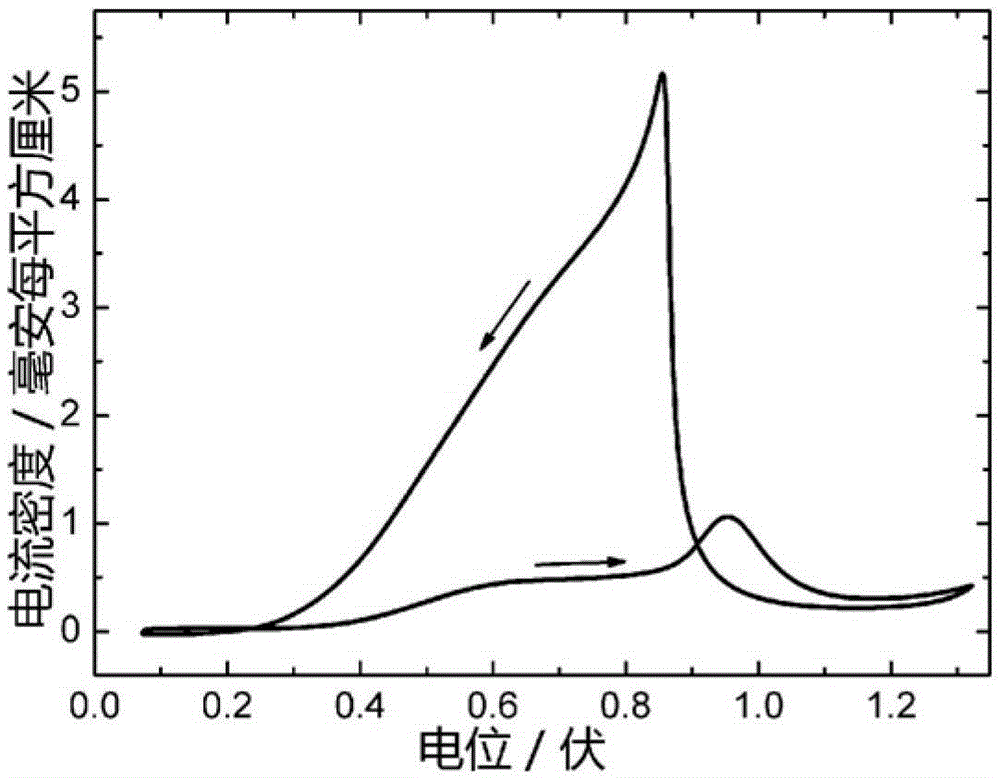

[0068] The nanoporous gold supported platinum ruthenium alloy catalyst sample of above-mentioned preparation is in 0.5mol / LH 2 SO 4 The cyclic voltammetry performance was tested in the solution, and the cyclic voltammetry curve was obtained as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com