Method for preparing low-silicon low-calcium low-aluminium vanadium liquid

A technology of vanadium liquid and low calcium, which is applied in the field of leaching vanadium extraction, can solve the problems of uninvolved, unproduced, high purity and concentration of vanadium liquid, etc., and achieve low cost, simple and easy-to-use process, and wide range of raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

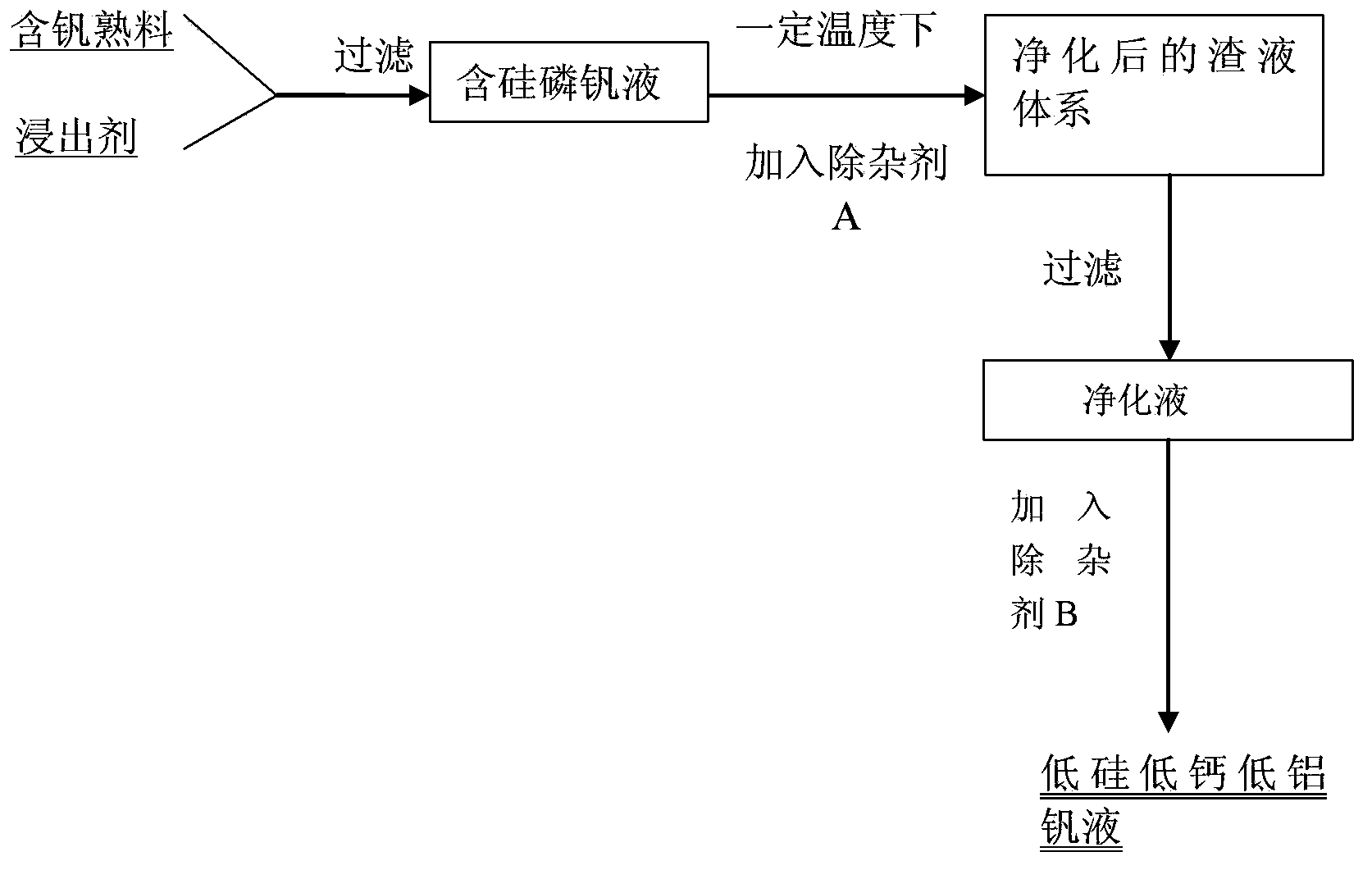

Method used

Image

Examples

example 1

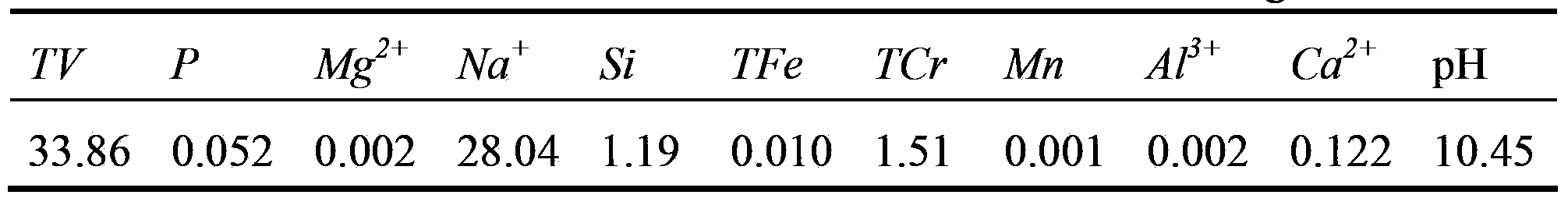

[0023] Add 300mL of common vanadium solution in Table 1 to a 500mL clean beaker, stir, heat to boiling, adjust the pH value of the solution system to 8, add 10g of impurity remover A (4g of aluminum sulfate and 6g of magnesium sulfate), react for 1h, Cool to room temperature, filter, after obtaining the filtrate, adjust the pH value of the solution system to 11, add 1g of impurity remover B (sodium oxalate), react for 1h, cool to room temperature, filter, and obtain Si content of 0.005g / L, Ca content The vanadium liquid is 0.005g / L and Al content is 0.01g / L.

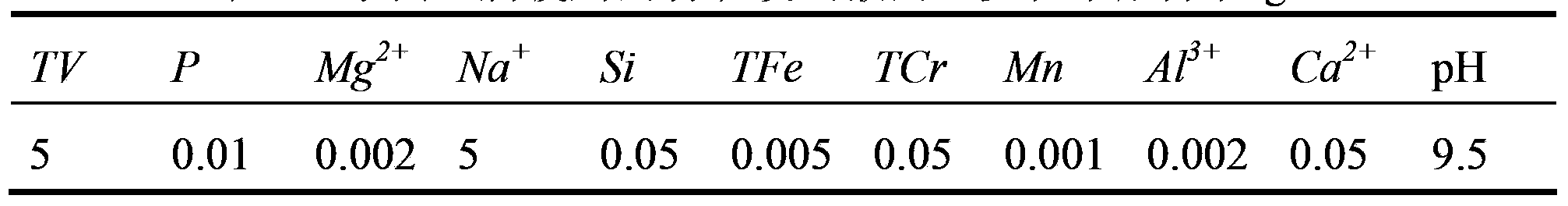

[0024] Table 2 shows the main chemical components of the vanadium-containing leaching solution used in Example 2 below.

[0025] Table 2 The main chemical composition table of the vanadium-containing leaching solution used in Example 2 / g L -1

[0026]

example 2

[0028] Add 300mL of common vanadium solution in Table 2 to a 500mL clean beaker, stir, heat to boiling, adjust the pH value of the solution system to 9, add 3g of impurity remover A (1.5g of aluminum sulfate and 1.5g of iron sulfate), and react 1h, cooled to normal temperature, filtered, after obtaining the filtrate, adjusted the pH value of the solution system to 9, added 2g of impurity remover B (potassium oxalate), reacted for 1h, cooled to normal temperature, filtered, obtained the Si content of 0.005g / L, Vanadium solution with Ca content of 0.005g / L and Al content of 0.01g / L.

[0029] Table 3 shows the main chemical components of the vanadium-containing leaching solution used in Example 3 below.

[0030] Table 3 Main chemical composition table of the vanadium-containing leaching solution used in Example 3 / g L -1

[0031]

example 3

[0033] Add 300mL of common vanadium solution in Table 3 to a 500mL clean beaker, stir, heat to boiling, adjust the pH value of the vanadium solution to 11, add 20g of impurity remover A (8g of aluminum sulfate and 12g of magnesium sulfate), react for 1h, and cool to normal temperature, filter, and after obtaining the filtrate, adjust the pH value of the solution system to 10; add 8g of impurity remover B (a solution made of sodium oxalate and potassium oxalate), react for 1h, cool to normal temperature, and filter to obtain a Si content of 0.005 g / L, a vanadium solution with a Ca content of 0.005 g / L and an Al content of 0.01 g / L.

[0034] In summary, the method of the present invention can use ordinary vanadium liquid to make low-silicon, low-aluminum, low-calcium (for example, Si element content is lower than 0.005g / L, Ca element content is lower than 0.005g / L and Al element content is lower than 0.01g / L) vanadium-containing solution. Moreover, the method of the present inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com