High-performance modified asphalt and preparation method thereof

A modified asphalt, high-performance technology, applied in building components, building insulation materials, construction, etc., can solve the problems of difficult production and processing of modifier addition, and achieve the effects of low price, energy reduction and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

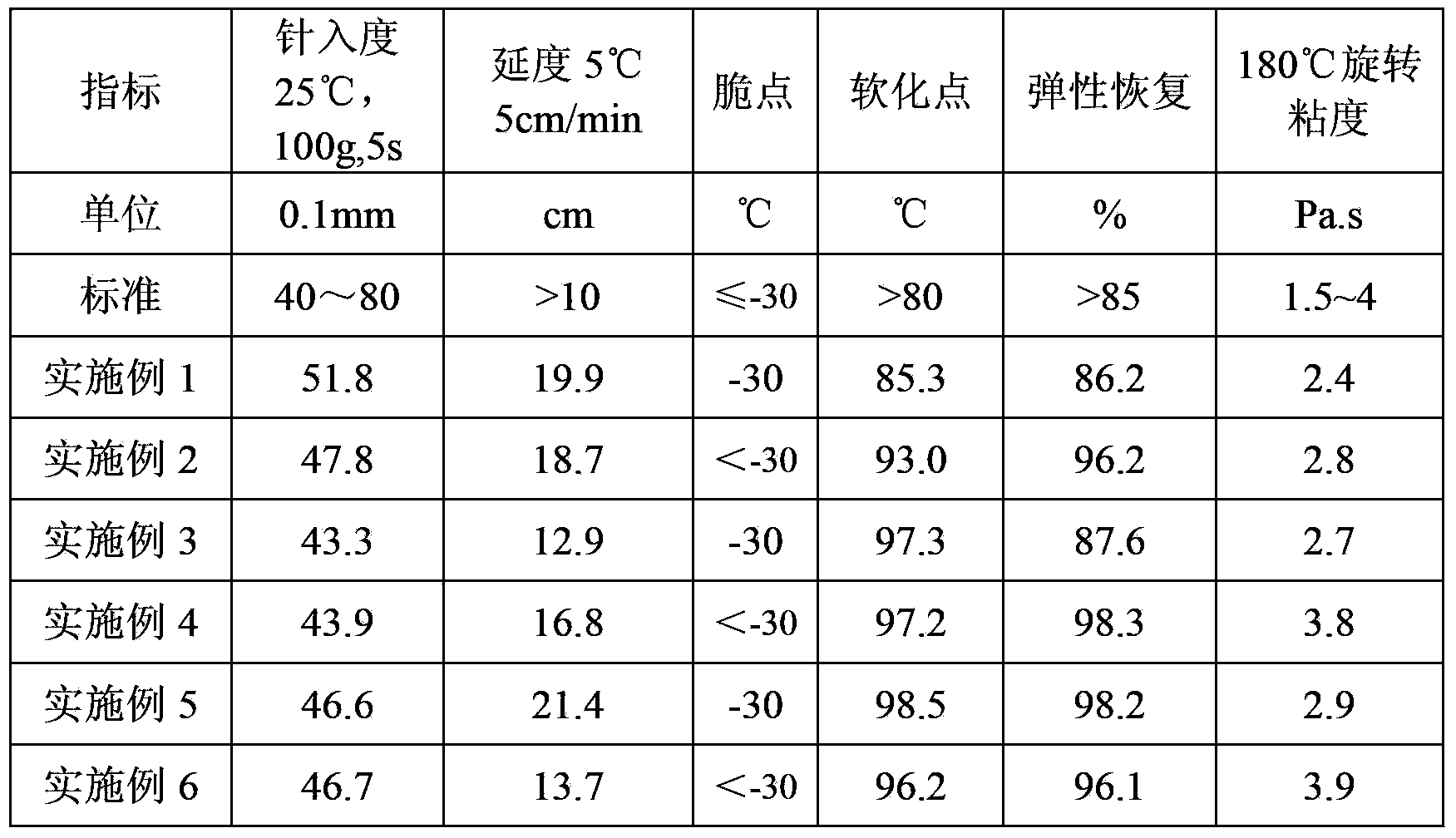

Embodiment 1

[0021] Take 7.8 tons of Liaohe No. 90 asphalt and heat it to 180°C in a reactor to obtain high-temperature asphalt. Add thermoplastic rubber accounting for 2% of the asphalt weight to the high-temperature asphalt, and use a high-speed shearing machine at a temperature >160°C. After grinding 3 times, pump it to the storage tank for development to obtain thermoplastic rubber modified asphalt; heat the thermoplastic rubber modified asphalt to 190°C, then add water less than 5%, metal content less than 0.4%, and ash content less than 8%. Number is 30 orders and accounts for the waste tire rubber powder of 20% of asphalt weight and accounts for 5% electric vacuum fly ash of asphalt weight, simultaneously, adds the rosin resin that accounts for the weight ratio of asphalt and is 3%, in mixing tank, temperature is >180°C, low-speed stirring (300-1000 rev / min) for 10 minutes, pumping to storage tank for 30 minutes, stirring evenly to obtain high-performance modified asphalt.

Embodiment 2

[0023] Take 8 tons of Liaohe No. 90 asphalt and heat it to 180°C in a reaction kettle, add thermoplastic rubber accounting for 4% of the asphalt weight to the high-temperature asphalt, and use a high-speed shearing machine in a mixing tank at 180°C to grind for 5 After one pass, pump it to the storage tank for development to obtain the developed product; obtain thermoplastic rubber modified asphalt; then add water less than 5%, metal content less than 0.4%, ash content less than 8%, mesh number is 30 mesh, accounting for 20% of asphalt weight waste tire rubber powder and 15% electric dust fly ash accounting for asphalt weight, at the same time, add 5% rosin resin accounting for asphalt weight ratio, in the mixing tank, heat up to 190 ° C, stir at low speed (300 ~ 1000 rpm / min) for 10 minutes, pumped to the storage tank for development, and stirred evenly to obtain high-performance modified asphalt.

Embodiment 3

[0025] Take 8.3 tons of Liaohe No. 90 asphalt and heat it to 180°C in a reaction kettle, add thermoplastic rubber accounting for 6% of the asphalt weight to the high-temperature asphalt, and use a high-speed shearing machine in a mixing tank at 180°C to perform high-speed shearing and grinding After 2 times, pump it to the storage tank for development to obtain a developed product; obtain thermoplastic rubber modified asphalt; then add water less than 5%, metal content less than 0.4%, ash content less than 8%, mesh number is 30 mesh, accounting for 15% of the weight of asphalt % waste tire rubber powder and 10% pozzolan by weight of asphalt, at the same time, add 6% rosin resin in the weight ratio of asphalt, in the mixing tank, the temperature is 170 ° C, low speed stirring (300 ~ 1000 rpm) 10 Minutes, pumped to the storage tank for development, stirred evenly, that is, high-performance modified asphalt.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com