Preparation method of near-infrared light response hydrogel

A near-infrared light-responsive, hydrogel technology is applied in the preparation of hydrogels and the preparation of light-stimulated-responsive hydrogels, which can solve the problems of rapid diffusion and unfavorable treatment, achieve a large selection range and enhance international competitiveness. , conducive to the effect of repeated use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Add 10g of polyethylene glycol to 100g of deionized water, stir and disperse, add 0.5g of copper sulfate pentahydrate and 2g of sodium sulfide respectively, and pre-react for 1 hour to obtain a mixed dispersion; then transfer the above mixed dispersion to a hydrothermal kettle , at 120°C, reacted for 12 hours; after the reaction was completed, cooled to 30°C, washed with deionized water, and dried to obtain copper sulfide powder.

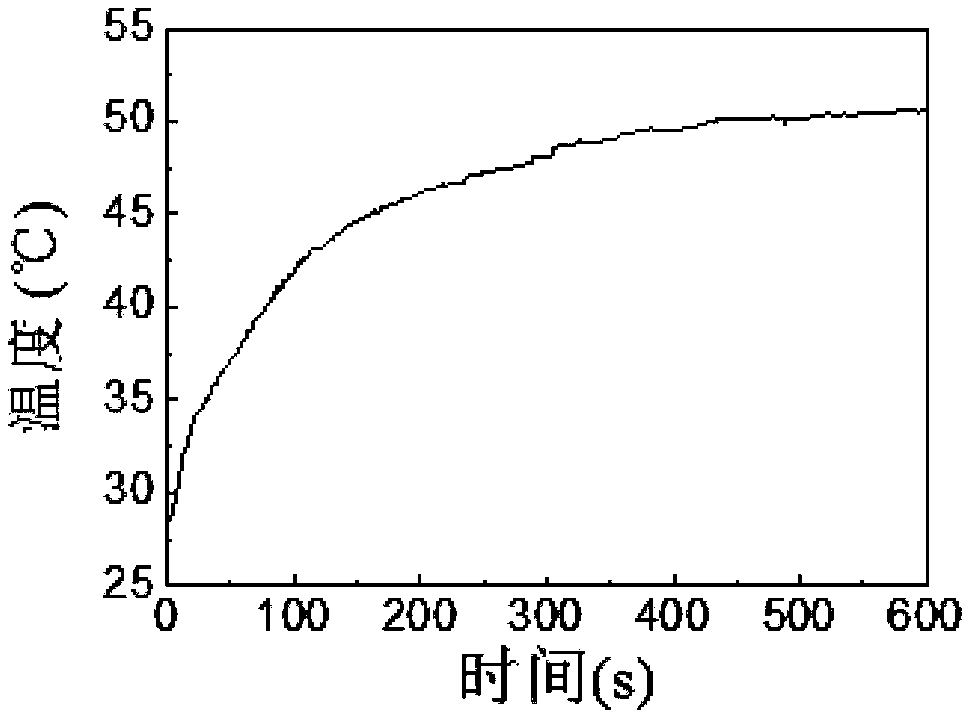

[0029] Add 0.02g of polyethylene glycol diacrylate, 2g of N-isopropylacrylamide, 0.01g of copper sulfide powder, 0.02g of ammonium persulfate, and 0.01g of sodium thiosulfate into 10g of deionized water to obtain a hydrogel prepolymerized liquid. The hydrogel pre-polymerization solution was polymerized at 25° C. for 8 hours to obtain a near-infrared light-responsive hydrogel. Under the irradiation of near-infrared light with a wavelength of 808 nm, the temperature of the hydrogel can increase by 20 °C within 10 minutes.

Embodiment 2

[0031] Add 20g of polyethylene glycol to 100g of deionized water to stir and disperse, add 0.4g of anhydrous copper chloride and 4g of ammonium sulfide respectively, and pre-react for 2 hours to obtain a mixed dispersion; then transfer the above mixed dispersion to a hydrothermal kettle , at 150°C, reacted for 8 hours; after the reaction was completed, cooled to 30°C, washed with deionized water, and dried to obtain copper sulfide powder.

[0032] Add 0.02g of polyethylene glycol diacrylate, 2g of acrylamide, 0.01g of copper sulfide powder, 0.02g of ammonium persulfate, and 0.02g of sodium thiosulfate into 10g of deionized water to obtain a hydrogel prepolymer solution. The hydrogel pre-polymerization solution was polymerized at 25° C. for 8 hours to obtain a near-infrared light-responsive hydrogel. Under the irradiation of near-infrared light with a wavelength of 808 nm, the temperature of the hydrogel can increase by 20 °C within 10 minutes.

Embodiment 3

[0034] Add 10g of polyvinylpyrrolidone into 100g of deionized water, stir and disperse, add 0.5g of copper sulfate pentahydrate and 2g of sodium sulfide respectively, and pre-react for 1 hour to obtain a mixed dispersion; then transfer the above mixed dispersion to a hydrothermal kettle, React at 150°C for 12 hours; after the reaction is over, cool to 40°C, wash with deionized water, and dry to obtain copper sulfide powder.

[0035] Add 0.02g of polyethylene glycol dimethacrylate, 2g of N-isopropylacrylamide, 0.02g of copper sulfide powder, 0.02g of sodium persulfate, and 0.05g of triethanolamine into 10g of deionized water to obtain a hydrogel prepolymerized liquid. The hydrogel pre-polymerization liquid was polymerized at 25° C. for 24 hours to obtain a near-infrared light-responsive hydrogel. Under the irradiation of near-infrared light with a wavelength of 980nm, the temperature of the hydrogel can increase by 40°C within 10 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com