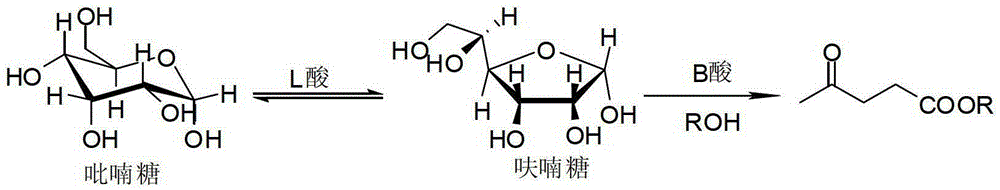

A kind of method that solid acid catalysis high yield prepares levulinic acid ester

A technology catalyzed by levulinic acid esters and solid acids, which is applied in the preparation of carboxylic acid esters, chemical instruments and methods, and the preparation of organic compounds. It can solve the problems of acid point loss and yield reduction, and achieve good reactivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Preparation of tin-containing molecular sieve Sn-Beta:

[0032] Take 20 parts of hydrogen-type Beta molecular sieve (H-Beta) (beta molecular sieve produced by Nankai Catalyst Factory) and mix with 400 parts of 13M nitric acid solution, heat to 100°C for 20 hours; filter, wash until neutral, put in an oven at 120°C After drying, transfer to a vacuum drying oven to dry at 180°C for 5 hours to remove water to obtain dealuminated molecular sieve (deAlBeta); take 5 parts of deAlBeta and dissolve it in 100 parts of benzene, then add 10 parts of anhydrous SnCl 4 , stirred at 25°C for 24h, filtered, washed with 1000 parts of benzene to remove free SnCl 4 , 550 ° C air activation 3h, after cooling to get Sn-Beta.

Embodiment 2

[0034] SBA-15-SO 3 Preparation of H:

[0035] Stir and dissolve 4 parts of polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer (P123, M=5800) with 121 parts of 1.9M hydrochloric acid solution; heat to 40°C after complete dissolution Slowly add 6.82 parts of tetraethyl silicate dropwise, pre-hydrolyze for 150 minutes, then add dropwise 1.61 parts of mercaptopropyltrimethoxysilane, and keep stirring at 40°C for 20 hours. After the reaction, put it into 400 parts of hydrothermal reaction kettle for aging at 120°C for 24 hours; cool it, filter it with a Buchner funnel to obtain a white solid, put it into a Soxhlet extractor, and use ethanol as the extraction agent to reflux and extract for 24 hours. ℃ vacuum oven drying for 10h to obtain SBA-15-SO 3 H.

Embodiment 3

[0037] Carbon-SO 3 Preparation of H:

[0038] Take 20 parts of microcrystalline cellulose and react at 450°C for 5 hours under the protection of argon to obtain black activated carbon; mix 4.3 parts of activated carbon with 300 parts of concentrated sulfuric acid and heat up to 120°C for sulfonation for 24 hours; after cooling, dilute to 1000 parts with water, and use Buchner funnel filtration, vacuum drying to obtain Carbon-SO 3 H.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com