Preparation method for coproduction of high-specific-capacitance active carbon and nano silicon dioxide from rice hull

A technology of nano-silica and high specific capacitance, which is applied in the field of comprehensive resource utilization and electrochemical supercapacitors, can solve the problems of complex preparation methods, high ash content of activated carbon, and long preparation time, and achieve simple preparation process, narrow pore size distribution, The effect of excellent specific capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Wash, dry and grind the rice husk;

[0026] (2) The rice husks treated in step (1) were carbonized at 400°C for 1.5 hours under the protection of nitrogen, treated with 10% hydrochloric acid, washed with water, and dried;

[0027] (3) Mix the carbonization product of step (2) with potassium hydroxide at a mass ratio of 1:3, and the volume-to-mass ratio of the added water to the mixture is 3:1 (mL / g), mix well, dry, and control the temperature rise Speed 10°C / min, activate at 750°C for 1h;

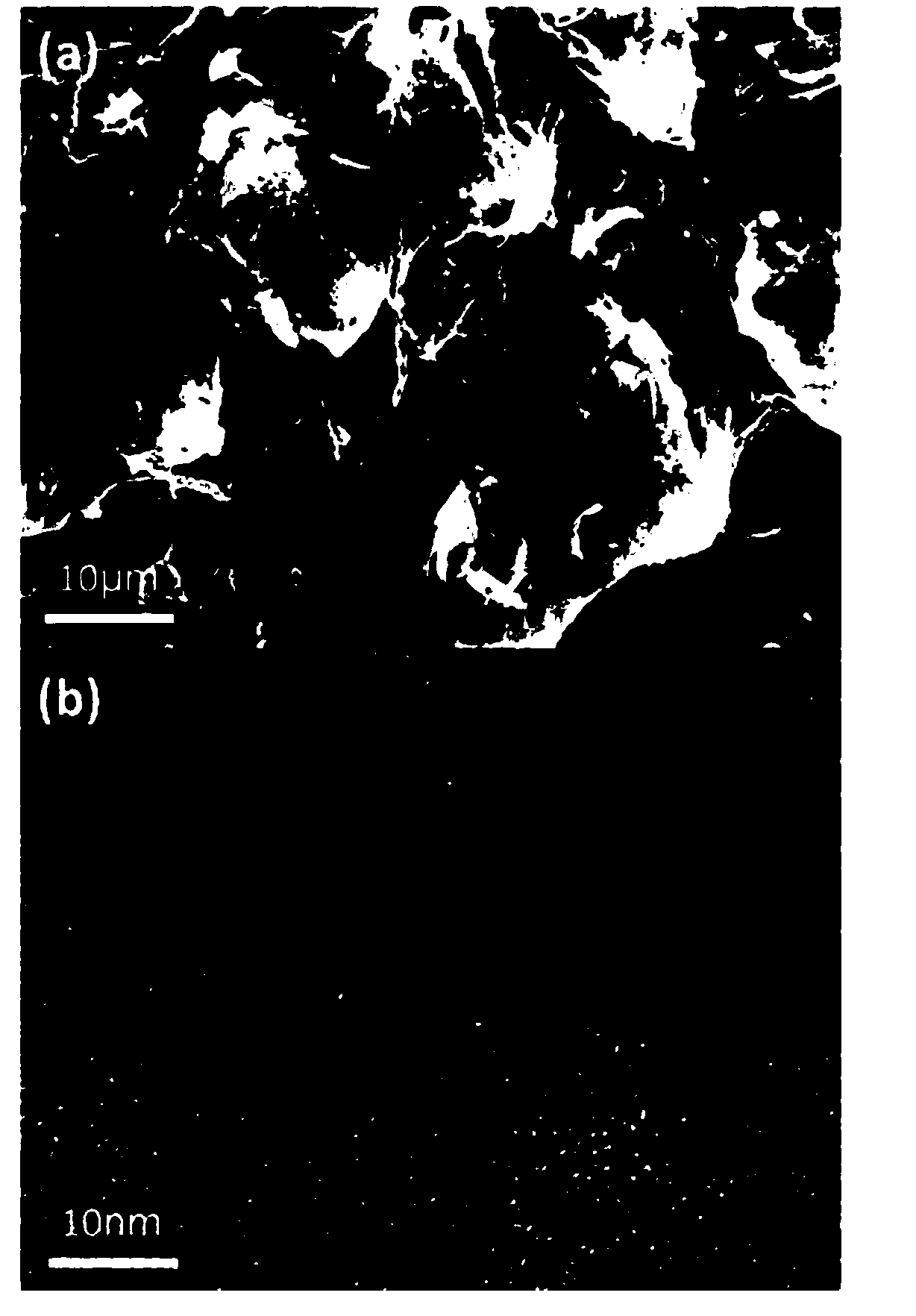

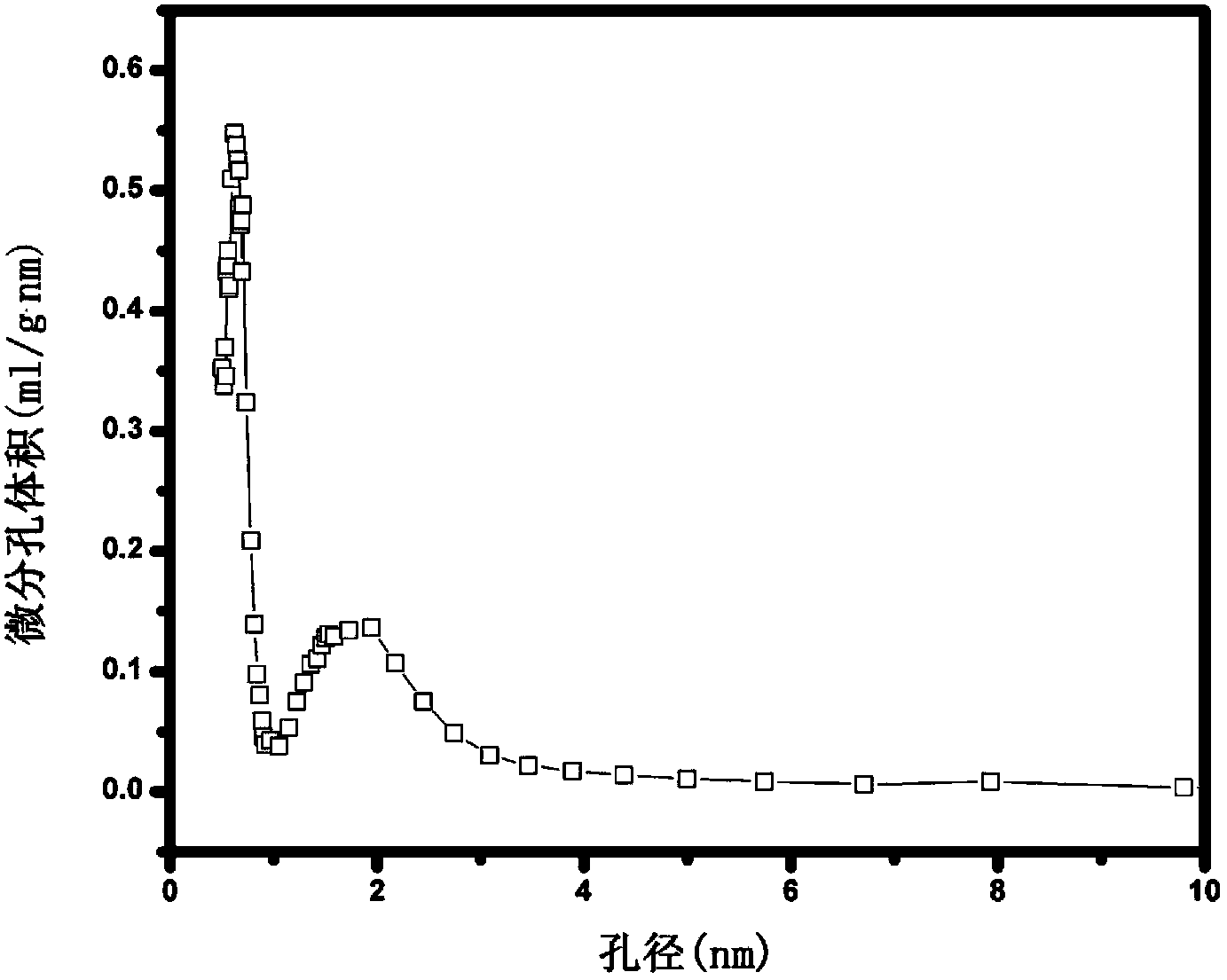

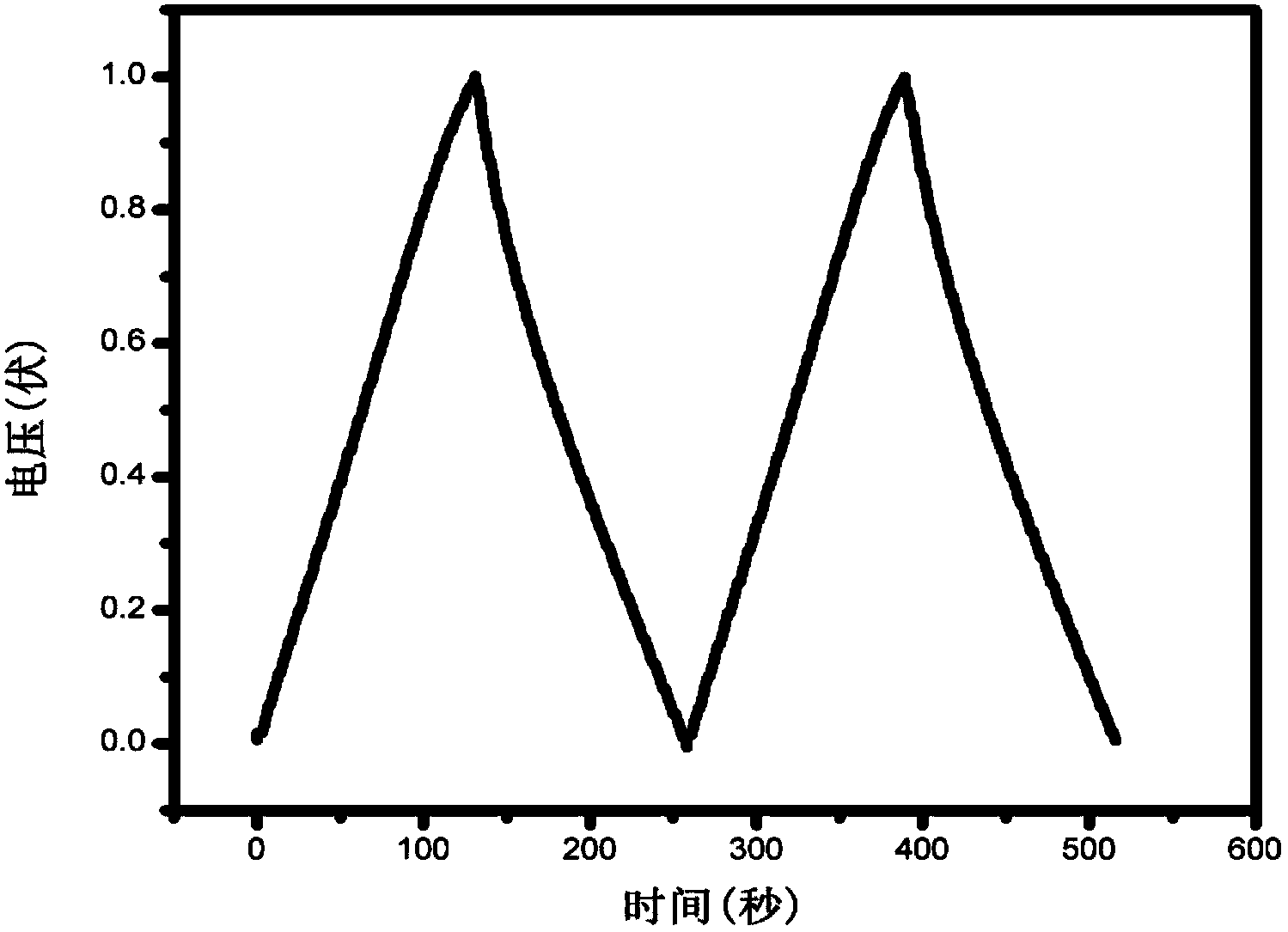

[0028] (4) Soak the activated product in water at 90°C, filter, wash with boiling water until neutral, and dry at 100°C for 12 hours to obtain a rice husk-based activated carbon material with a specific surface area of 3235m 2 / g, average pore diameter 2.0nm;

[0029] (5) Recover the filtrate in step (4), adjust the temperature to 70°C, add hydrochloric acid solution with a concentration of 5%, control the hydrochloric acid drop rate to 0.2ml / min, until pH=6.5 is the end po...

Embodiment 2

[0033] (1) Wash, dry and grind the rice husk;

[0034] (2) The rice husks treated in step (1) were carbonized at 400°C for 2 hours under the protection of argon, treated with 5% hydrochloric acid, washed with water, and dried;

[0035] (3) Mix the carbonization product of step (2) with potassium hydroxide at a mass ratio of 1:4, and the volume-to-mass ratio of the added water to the mixture is 2:1 (mL / g), mix well, dry, and control the temperature rise Speed 10°C / min, activate at 700°C for 2h;

[0036] (4) Soak the activated product in water at 100°C, filter, wash with boiling water until neutral, and dry at 100°C for 12 hours to obtain a rice husk-based activated carbon material with a specific surface area of 2824m 2 / g, the average pore diameter is 2.4nm;

[0037](5) Recover the filtrate in step (4), adjust the temperature to 80°C, add a sulfuric acid solution with a concentration of 12%, control the sulfuric acid solution at a rate of 0.5ml / min, until the end point i...

Embodiment 3

[0041] (1) Wash, dry and grind the rice husk;

[0042] (2) The rice husks treated in step (1) were carbonized at 450°C for 1 hour under the protection of nitrogen, treated with 10% sulfuric acid, washed with water, and dried;

[0043] (3) Mix the carbonization product of step (2) with sodium hydroxide at a mass ratio of 1:3, and the volume-to-mass ratio of the added water to the mixture is 4:1 (mL / g), mix well, dry, and control the temperature rise Speed 15°C / min, activate at 700°C for 2h;

[0044] (4) Soak the activated product in water at 70°C, filter, wash with boiling water until neutral, and dry at 100°C for 12 hours to obtain a rice husk-based activated carbon material with a specific surface area of 2932m 2 / g, the average pore diameter is 2.2nm;

[0045] (5) Recover the filtrate in step (4), adjust the temperature to 60°C, add a hydrochloric acid solution with a concentration of 5%, control the sulfuric acid solution at a rate of 0.6ml / min, until the end point is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com