Carbon-coated cobalt molybdate network nanosheet array material, preparation method and application

A technology of nanosheet array and cobalt molybdate, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, and can solve the problem of reducing the electrochemical activity of materials, the decrease of electrical conductivity of composite materials, and low electrical conductivity, etc. problems, to achieve the effect of improving reaction kinetics and material utilization, improving specific capacitance and cycle performance, and good electrical conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

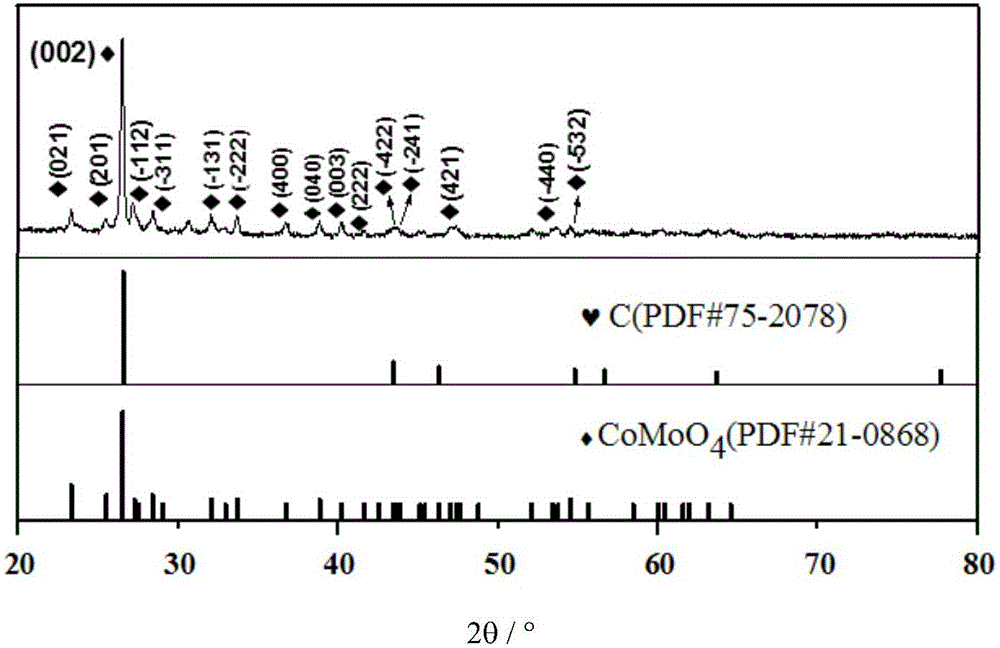

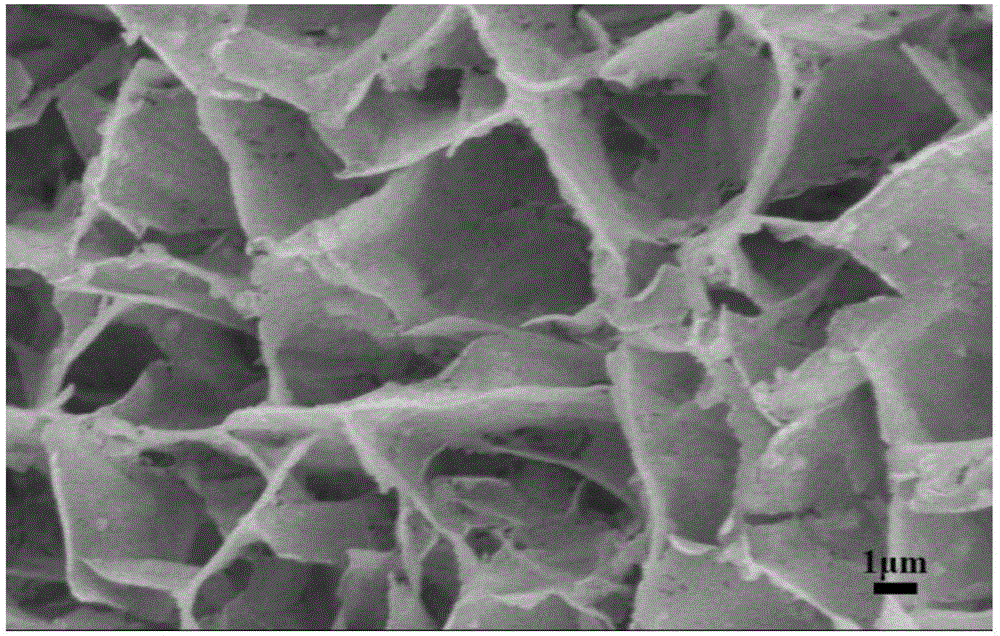

[0040] Dissolve 0.875g cobalt nitrate and 0.725g sodium molybdate in 60mL deionized water, transfer the resulting mixed solution into a 100mL polytetrafluoroethylene reactor, and place a 2×2cm 2 Dip the foamed nickel into the mixed solution in the reaction kettle, seal the reaction kettle and put it in a blast drying box and heat it to 120°C for 5 hours. After the reaction kettle is naturally cooled to room temperature, take out the surface growth cobalt molybdate mesh nanosheet array The foamed nickel is washed with deionized water and dried at 60℃;

[0041] Dissolve 0.119 g of glucose in 60 mL of deionized water, transfer the obtained glucose solution into a 100 mL polytetrafluoroethylene reactor, immerse the nickel foam on the surface of the cobalt molybdate mesh nanosheet array in the glucose solution, and react After the kettle is airtight, it is placed in a blast drying box and heated to 120°C for 5 hours. After the reaction kettle is naturally cooled to room temperature, th...

Embodiment 2

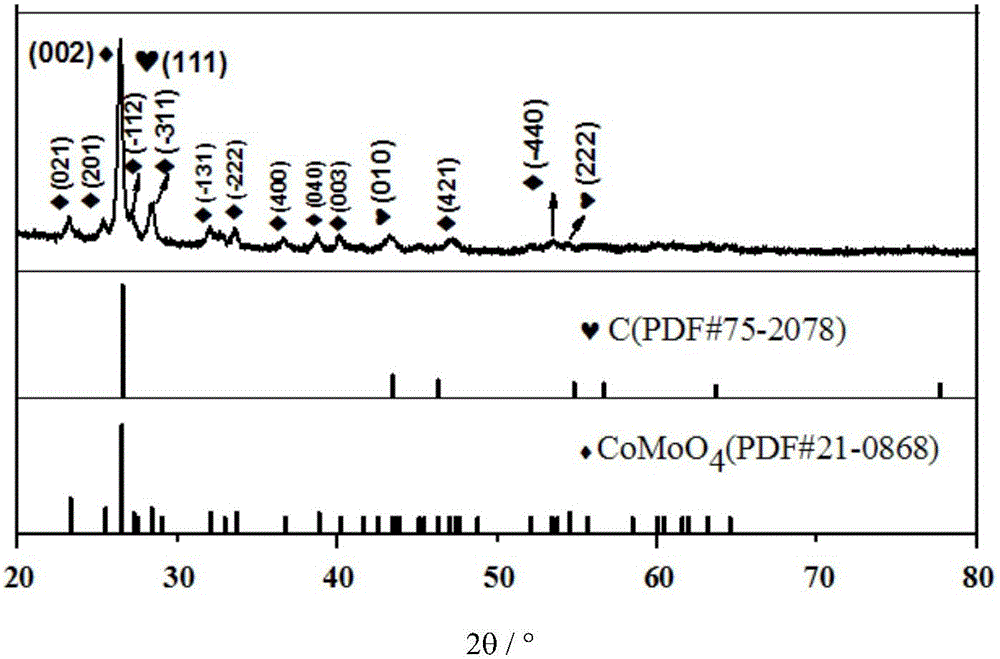

[0050] Take 0.524g of cobalt nitrate and 0.436g of sodium molybdate dissolved in 60mL of deionized water, transfer the resulting mixed solution into a 100mL polytetrafluoroethylene reactor, the 2×2cm 2 Dip the foamed nickel into the mixed solution in the reaction kettle, seal the reaction kettle and put it in a blast drying box and heat it to 110°C for 6 hours. After the reaction kettle is naturally cooled to room temperature, take out the surface growth cobalt molybdate mesh nanosheet array The foamed nickel is washed with deionized water and dried at 50℃;

[0051] Dissolve 0.06g of sucrose in 60mL of deionized water, transfer the resulting sucrose solution into a 100mL polytetrafluoroethylene reactor, and immerse the foamed nickel on the surface of the cobalt molybdate mesh nanosheet array in the sucrose solution, and react After the kettle is airtight, it is put into a blast drying box and heated to 110°C for 6h. After the kettle is naturally cooled to room temperature, take ou...

Embodiment 3

[0055] Dissolve 1.222g cobalt nitrate and 1.016g sodium molybdate in 60mL deionized water, transfer the resulting mixed solution into a 100mL polytetrafluoroethylene reactor, and place 2×2cm 2 Dip the foamed nickel into the mixed solution in the reaction kettle, seal the reaction kettle and put it in a blast drying box and heat it to 130°C for 4 hours. After the reaction kettle is naturally cooled to room temperature, take out the cobalt molybdate net-like nanosheet array grown on the surface The foamed nickel is washed with deionized water and dried at 70℃;

[0056] Dissolve 0.237g glucose in 60mL deionized water, transfer the resulting glucose solution into a 100mL polytetrafluoroethylene reactor, immerse the nickel foam on the surface of the cobalt molybdate mesh nanosheet array in the glucose solution, and react After the kettle is airtight, it is put into a blast drying box and heated to 130°C for 4h. After the reaction kettle is naturally cooled to room temperature, the gluc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com