Fe-MOF-polyaniline composite material and preparation method and application thereof

A composite material and polyaniline technology, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the obstacles to the mass use of such polymer-based electrodes, high preparation costs, carbon film and precious metal film preparation process Complexity and other issues, to achieve the effect of easy operation, simple preparation method, such as capacitance and rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Dissolve terephthalic acid (300mg) and ferric nitrate (800mg) in DMF (40mL) respectively, mix the two solutions evenly, reflux at 120°C for 40min, add 40mL of acetonitrile, centrifuge and dry to obtain iron-MOF Precursor.

[0024] (2) Aniline (1.14mg) is dissolved in deionized water to form aniline solution, the concentration of aniline solution is 2mmol / L, and the iron-MOF precursor (20mg) in step (1) is soaked in aniline solution (5ml) , Polymerized at -5°C for 12 hours to obtain an iron-MOF-polyaniline composite material, which was designated as Fe-MOF-PANI-1.

Embodiment 2

[0026] (1) Dissolve terephthalic acid (300mg) and ferric nitrate (800mg) in DMF (40mL) respectively, mix the two solutions evenly, reflux at 120°C for 40min, add 40mL of acetonitrile, centrifuge and dry to obtain iron-MOF Precursor.

[0027] (2) Aniline (3.42mg) is dissolved in deionized water to form aniline solution, the concentration of aniline solution is 6mmol / L, and the iron-MOF precursor (20mg) in step (1) is soaked in aniline solution (5ml) , Polymerized at -5°C for 12 hours to obtain an iron-MOF-polyaniline composite material, which was designated as Fe-MOF-PANI-2.

Embodiment 3

[0029] (1) Dissolve terephthalic acid (300mg) and ferric nitrate (800mg) in DMF (40mL) respectively, mix the two solutions evenly, reflux at 120°C for 40min, add 40mL of acetonitrile, centrifuge and dry to obtain iron-MOF Precursor.

[0030] (2) Aniline (5.7mg) is dissolved in deionized water to form aniline solution, the concentration of aniline solution is 10mmol / L, and the iron-MOF precursor (20mg) in step (1) is soaked in aniline solution (5ml) , Polymerized at -5°C for 12 hours to obtain an iron-MOF-polyaniline composite material, which was designated as Fe-MOF-PANI-3.

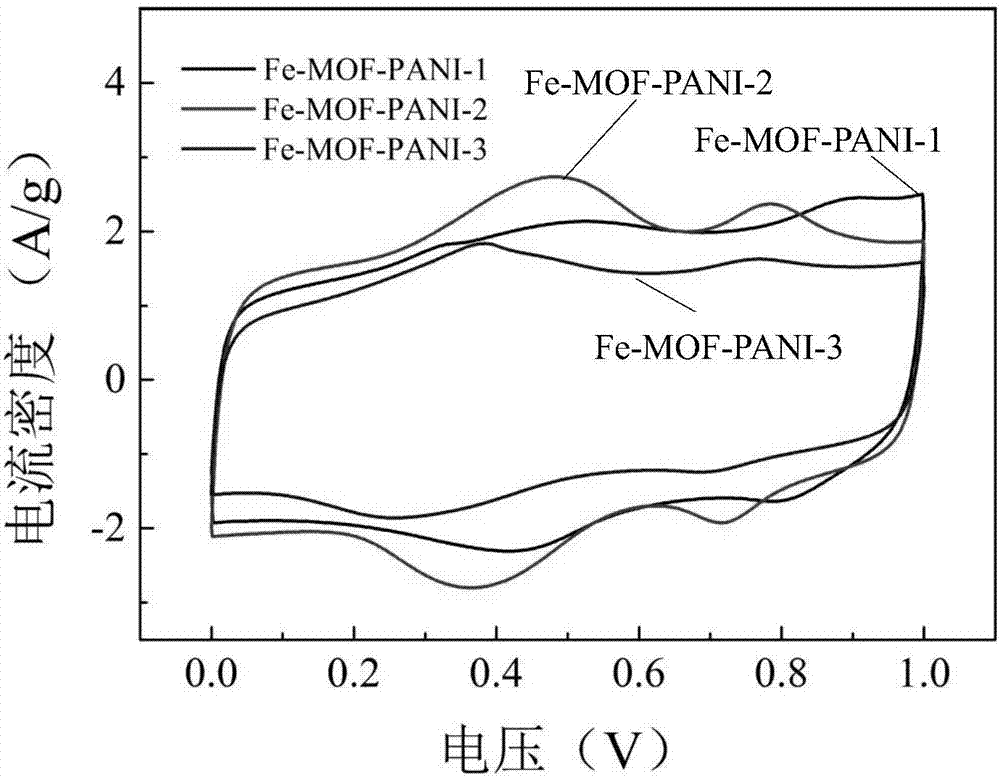

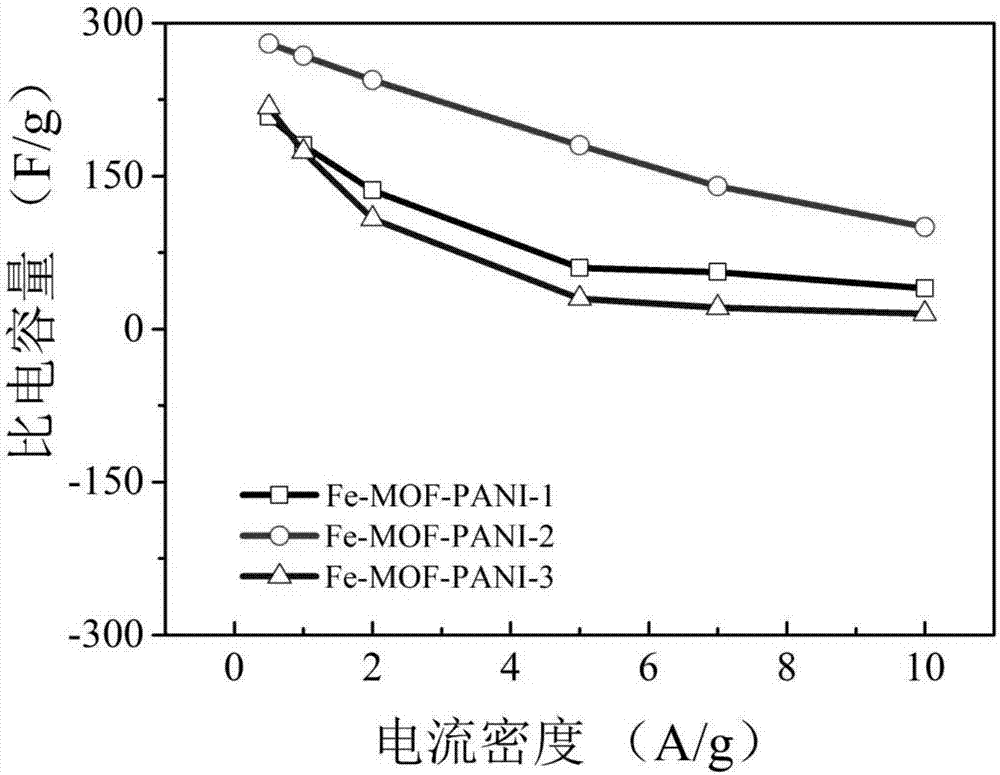

[0031] Electrochemical test results show that: figure 1 The iron-MOF-polyaniline composites prepared in Example 1, Example 2 and Example 3 all show obvious redox peaks. figure 2 The iron-MOF-polyaniline composites prepared in Example 1, Example 2 and this Example 3 all have good specific capacitance, and the iron-MOF-polyaniline composites prepared in Example 2 have a capacity of 0.5 Under the curren...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com