Method for preparing cobalt selenide super-capacitor material by non-template electrodeposition method

A technology of supercapacitors and electrodeposition methods, applied in chemical instruments and methods, hybrid/electric double layer capacitor manufacturing, hybrid capacitor electrodes, etc., can solve the problems of poor cycle stability of conductive polymers, rare research and development of selenides, sulfides Problems such as high resistivity, to achieve the effect of facilitating diffusion and migration, favorable specific surface area, and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

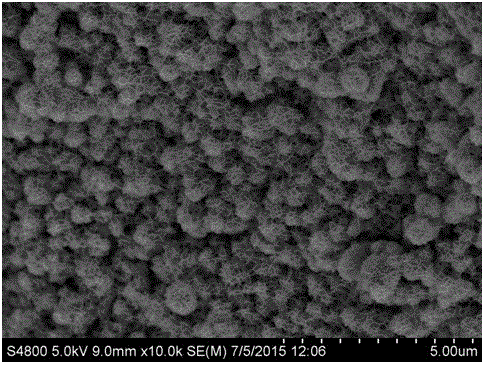

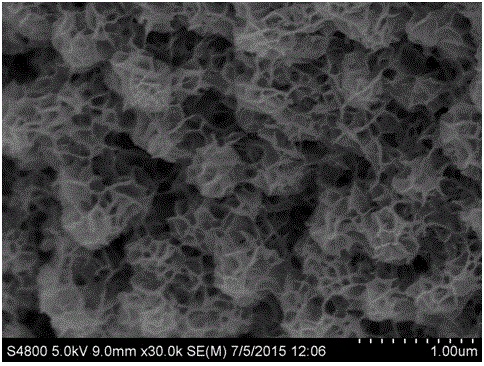

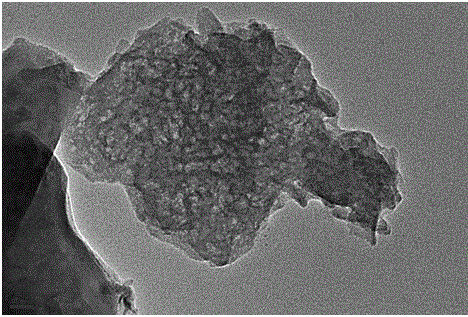

Image

Examples

Embodiment 1

[0031] Use dilute hydrochloric acid, deionized water and ethanol to wash the foamed nickel mesh successively and then dry it: configure 0.02mol / L Na 2 SeO 3 solution and 0.02mol / L Co(CH 3 COO) 2 solution, then add 0.1mol / L CH 3 Mix the COOLi solution evenly to obtain the precursor solution; immerse the cleaned nickel mesh in the precursor solution, and scan at 25°C under the condition of electrochemical deposition from -1.2V to 0.2V at a rate of 10mV / s, and scan for 15 Second, it can be observed that the surface of the nickel mesh is gradually covered by a layer of black substance. After the reaction is completed, the product is rinsed with deionized water and ethanol respectively and dried at 60°C for 6 hours to obtain the product.

Embodiment 2

[0033] Use dilute hydrochloric acid, deionized water and ethanol to wash the foamed nickel mesh and dry it: configure 0.01mol / L Na 2 SeO 3 solution and 0.01mol / L Co(CH 3 COO) 2 solution, then add 0.05mol / L CH 3 Mix the COOLi solution evenly to obtain the precursor solution; immerse the cleaned nickel mesh in the precursor solution, and scan at 50°C at a rate of 20mV / s from -1.2V to 0.2V under the electrochemical deposition conditions, and scan for 10 Second, it can be observed that the surface of the nickel mesh is gradually covered by a layer of black substance. After the reaction is completed, the product is rinsed with deionized water and ethanol respectively and dried at 60°C for 6 hours to obtain the product.

Embodiment 3

[0035] Use dilute hydrochloric acid, deionized water and ethanol to wash the foamed nickel mesh successively and dry it: configure 0.005mol / L Na 2 SeO 3 solution and 0.005mol / L Co(CH 3 COO) 2 solution, then add 0.2mol / L CH 3 Mix the COOLi solution evenly to obtain the precursor solution; immerse the cleaned nickel mesh in the precursor solution, and scan at 75°C from -1.2V to 0.2V at a rate of 5mV / s under the electrochemical deposition conditions, and scan for 20 Second, it can be observed that the surface of the nickel mesh is gradually covered by a layer of black substance. After the reaction is completed, the product is rinsed with deionized water and ethanol respectively and dried at 60°C for 6 hours to obtain the product.

[0036] The chemical raw material used in the above examples Co(CH 3 COO) 2 、Na 2 SeO 3 、CH 3 All COOLi are analytically pure, and the resistance of deionized water is 18.0-18.5MΩ.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Specific capacitance value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com