Gas diffusion layer of proton exchange membrane fuel cell and its preparation method

A gas diffusion layer and proton exchange membrane technology, which is applied to fuel cell components, fuel cells, electrical components, etc., can solve the problems of easy blockage of pores in the microporous layer, time-consuming, complicated process, etc. The effect of large-scale production, reduction of preparation process, and wide source of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

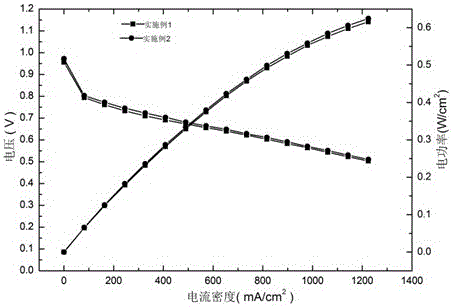

Embodiment 1

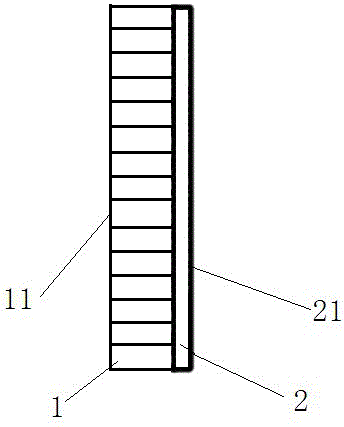

[0034] (1) Adopting aperture is 0.15mm, the nickel mesh that thickness is 0.2mm is used as substrate, after its surface is cleaned, adopts vacuum evaporation method to plate the carbon that one deck thickness is 0.003 millimeter on its surface, prepares the gas diffusion layer base.

[0035] (2) ①Weigh 10g of acetylene black, and gradually disperse it in 40ml 5% X-100 by cell crushing; ②Weigh 7.14g of 60% PTFE solution, add 4g of water to dilute, then add dropwise to ① In the acetylene black slurry, prepare a slurry with a PTFE load of 30%; ③ take 8g of silicon dioxide and 8g of ammonium chloride and dissolve them in ②; ④ take 20g PEG-600 and add it dropwise to the above ③, drop After the addition was complete, ultrasonication was performed for 30 minutes to obtain a carbon material slurry.

[0036] (3) Prepare a microporous layer on a carbon fiber fabric with a thickness of 0.003 mm by scraping the prepared carbon material slurry. The scraping thickness of the microporous la...

Embodiment 2

[0041] (1) A nickel mesh with an aperture of 0.3 mm and a thickness of 0.15 mm is used as the substrate. After the surface is cleaned, a layer of carbon with a thickness of about 0.003 mm is plated on the surface by vacuum evaporation to obtain a gas diffusion layer. base.

[0042] (2) ① Weigh 15g of acetylene black, and gradually disperse it in 90ml 3% X-100 by means of cell crushing; ②Weigh 6.24g of 60% PTFE solution, add 3g of water to dilute, and add dropwise to ① In the acetylene black slurry, prepare a slurry with a PTFE load of 20%; ③ take 9g of silicon dioxide and 9g of ammonium chloride and dissolve them in ②; ④ take 36g PEG-600 and add it dropwise to the above ③, drop After the addition was complete, ultrasonication was performed for 30 minutes to obtain a carbon material slurry.

[0043] (3) Prepare a microporous layer on a carbon fiber fabric with a thickness of 0.006 mm by scraping the prepared carbon material slurry. The scraping thickness of the microporous lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com