Au(111)-like nano-particle non-enzyme glucose sensor electrode, and preparation method and application of same

A glucose sensor and nanoparticle technology, applied in the direction of electrochemical variables of materials, etc., to achieve the effects of good market value, good selectivity, and short preparation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Pretreatment of conductive substrate:

[0034] Wipe the indium tin oxide (ITO) conductive glass with ethanol first, and then ultrasonically clean it with acetone, isopropanol, and ultrapure water for 20 minutes. Then put it into a mixture of deionized water, ammonia water (mass concentration 25%-28%) and hydrogen peroxide (mass concentration 30%), wherein the volume ratio of ionized water, ammonia water and hydrogen peroxide is 5:1:1, After heating and boiling for 30 minutes, wash with ultrapure water, blow dry with high-purity nitrogen, and set aside.

[0035] (2) Preparation of enzyme-free glucose sensor electrodes:

[0036]In 40mL electrolyte composed of 0.1mol / L sodium perchlorate and 0.0001mol / L chloroauric acid, ITO conductive glass is used as working electrode, platinum sheet is used as counter electrode, saturated calomel electrode is used as reference electrode, ITO electrode is The area is 0.4cm 2 . Before deposition, it can be blown with high-purity n...

Embodiment 2

[0038] (1), pretreatment of conductive substrate: same as embodiment 1

[0039] (2) Preparation of enzyme-free glucose sensor electrodes:

[0040] In 40mL electrolyte composed of 0.1mol / L sodium perchlorate and 0.0001mol / L chloroauric acid, ITO conductive glass is used as working electrode, platinum sheet is used as counter electrode, saturated calomel electrode is used as reference electrode, ITO electrode is The area is 0.4cm 2 . Before deposition, it can be blown with high-purity nitrogen for 30 minutes to remove dissolved oxygen in the electrolyte, and then use chronoamperometry to jump from the open circuit potential of 0.74V to -0.8V for 10s, and then use cyclic voltammetry at - Scan 500 cycles within the potential range of 0.04 to +0.3V, further electrodeposit the ITO electrode, wash the ITO electrode with deionized water, store it in deionized water, and store it at 4°C for later use.

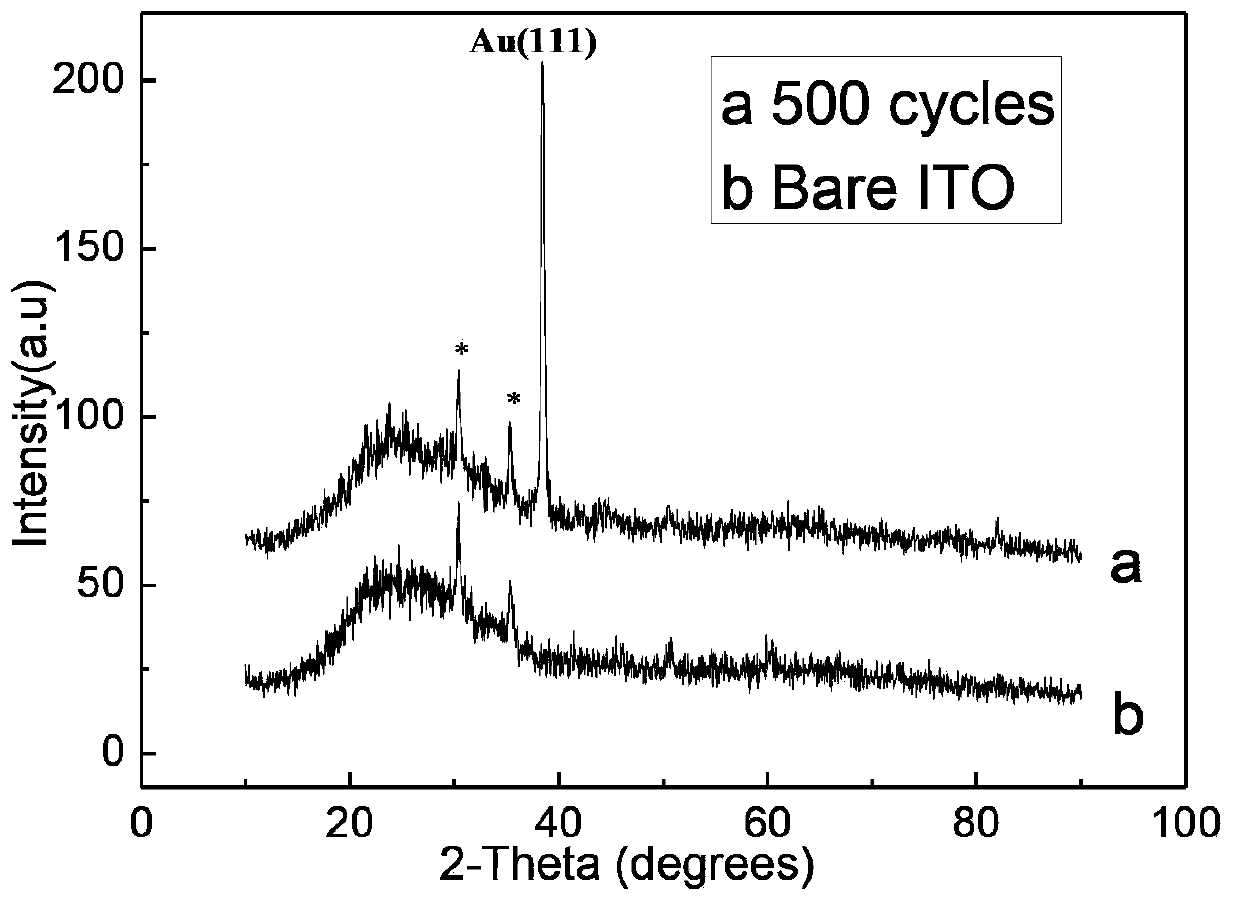

[0041] figure 1 It is a low-resolution field emission scanning electron microsc...

Embodiment 3

[0047] (1), pretreatment of conductive substrate: same as embodiment 1

[0048] (2) Preparation of enzyme-free glucose sensor electrodes:

[0049] In 40mL electrolyte composed of 0.1mol / L sodium perchlorate and 0.0001mol / L chloroauric acid, ITO conductive glass is used as working electrode, platinum sheet is used as counter electrode, saturated calomel electrode is used as reference electrode, ITO electrode is The area is 0.4cm 2 . Before deposition, it can be blown with high-purity nitrogen for 30 minutes to remove dissolved oxygen in the electrolyte, and then use chronoamperometry to jump from the open circuit potential of 0.74V to -0.8V for 10s, and then use cyclic voltammetry at - Scan 300 cycles within the potential range of 0.04 to +0.3V, further electrodeposit the ITO electrode, wash the ITO electrode with deionized water, store it in deionized water, and store it at 4°C for later use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com