Composite tube alternatively using cold energy and heat energy

A combined tube, cold and heat technology, applied in the direction of tubular elements, heat exchange equipment, heat exchanger types, etc., can solve the problems of energy consumption, deterring, disinfection and sterilization requirements can not fully achieve the desired effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

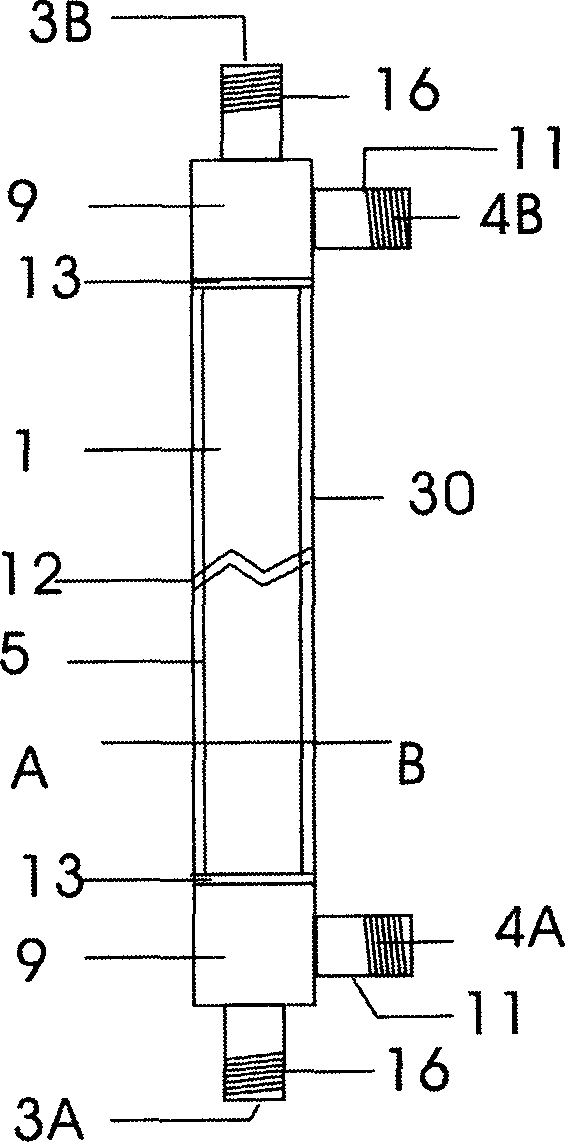

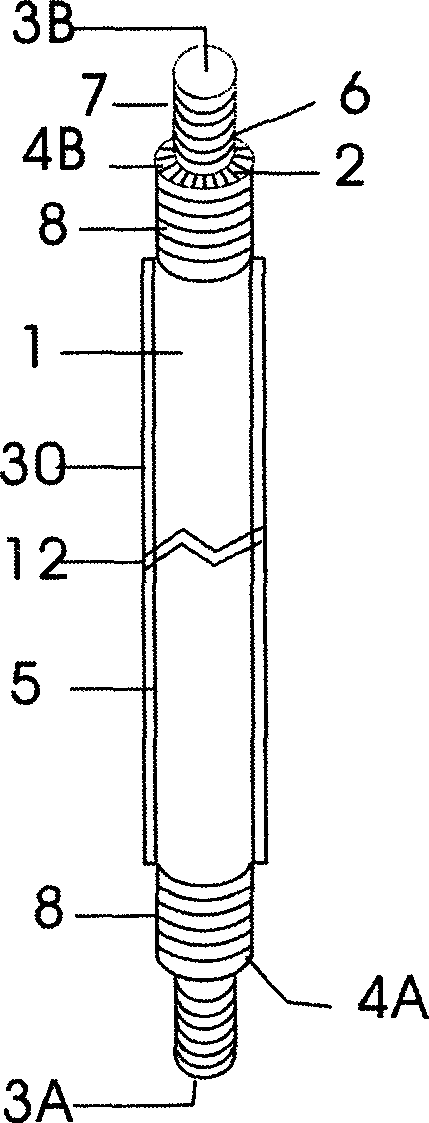

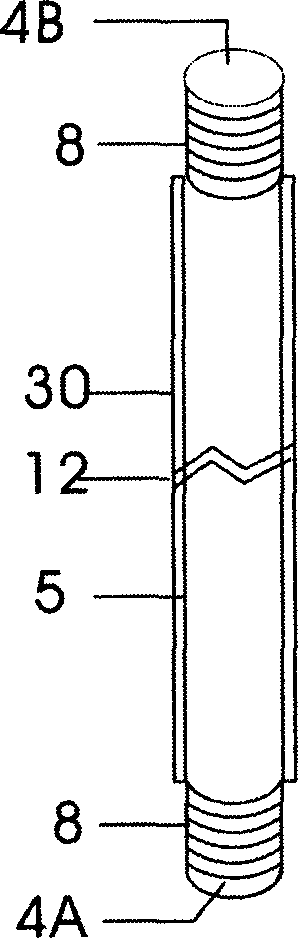

[0010] 1. Manufacturing method of composite tube

[0011] 1. Material and production method of inner tube

[0012] The production of the inner tube is very important in terms of materials. The material selection of the inner tube should be made of materials with good heat dissipation effect, good structural strength, no chemical reaction to water quality, suitable for casting processing and easy screw teeth after forming, such as copper, Aluminum, aluminum alloy and other materials. Since the tube wall of the inner tube and the heat-conducting sheet are integrally connected, casting is suitable for the production method. The inner tube is made of aluminum alloy as an example. This work can be done by an aluminum alloy casting company, using their advanced technology and equipment to complete the inner tube casting. The material produced by the aluminum alloy company also needs to remove the heat-conducting sheet at both ends for the installation of the water-dividing sleeve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com