A filter extrusion cutting system for rubber compound

A rubber compounding, extrusion and conveying technology, applied in recycling technology, metal processing, plastic recycling, etc., can solve the problems of small output, limited internal space, large volume, etc., to improve elasticity and toughness, and facilitate cleaning and maintenance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below with reference to the examples. The following examples are illustrative, not restrictive, and the protection scope of the present invention cannot be limited by the following examples.

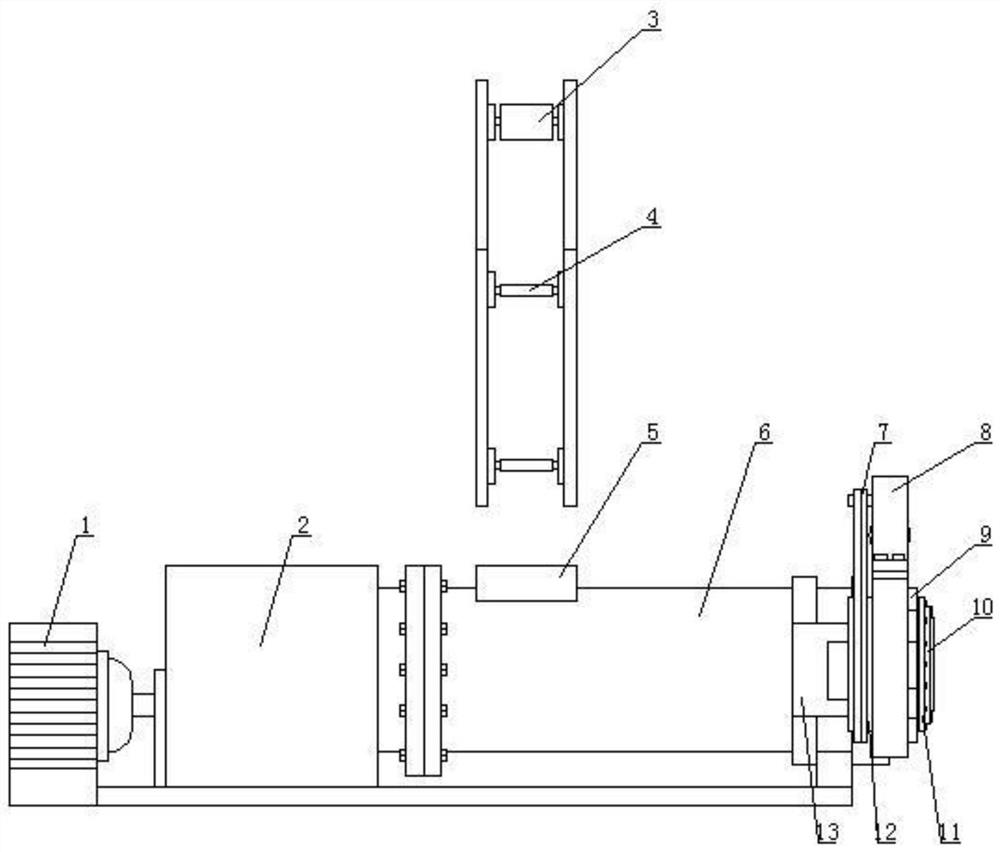

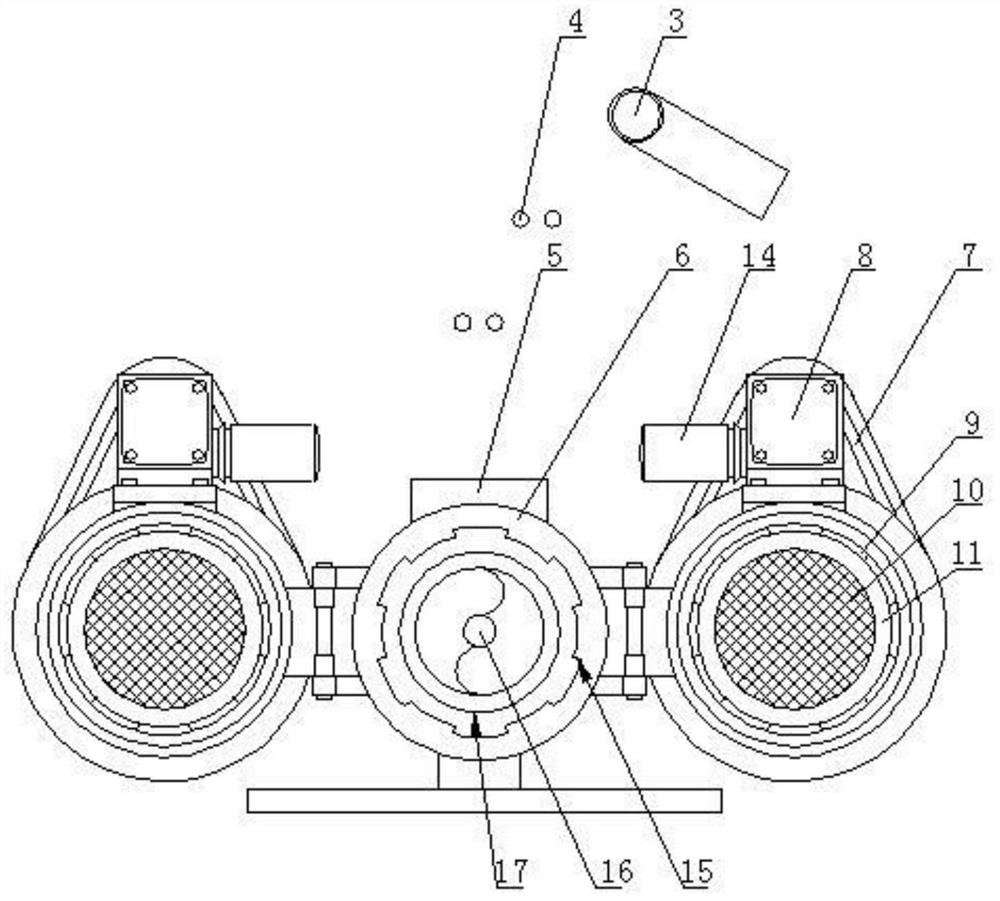

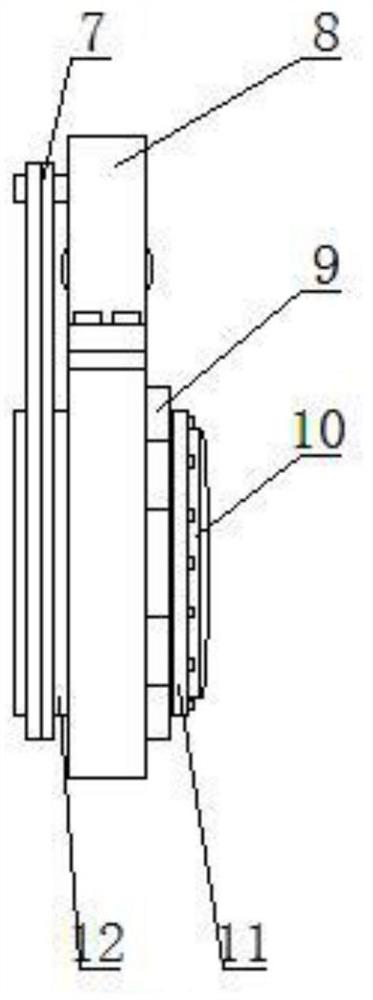

[0024] A filter extrusion cutting system for rubber compounding, the innovation of the present utility is that it includes a lifting device, a tablet pressing device, an extrusion conveying device and a filtering and cutting device, the lifting device includes a lifting roller 3, and the discharge of the lifting roller is The side is located above the filtering device, the tablet pressing device is installed between the lifting roller and the feed port 5 of the extrusion conveying device, the filtering and cutting device is installed at the outlet of the extrusion conveying device, and the lifting roller It is used to lift the belt-shaped rubber compound to be filtered to the top of the extrusion conveyor, and the tableting device is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com