Silicon dioxide aerogel compound fabric, preparation method and military tent cloth

A technology of silica and composite fabrics, applied in textiles and papermaking, fiber types, fiber treatment, etc., can solve the problems of inconvenient use and increased tent weight, and achieve the effects of non-combustibility, good explosion-proof performance, and good thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

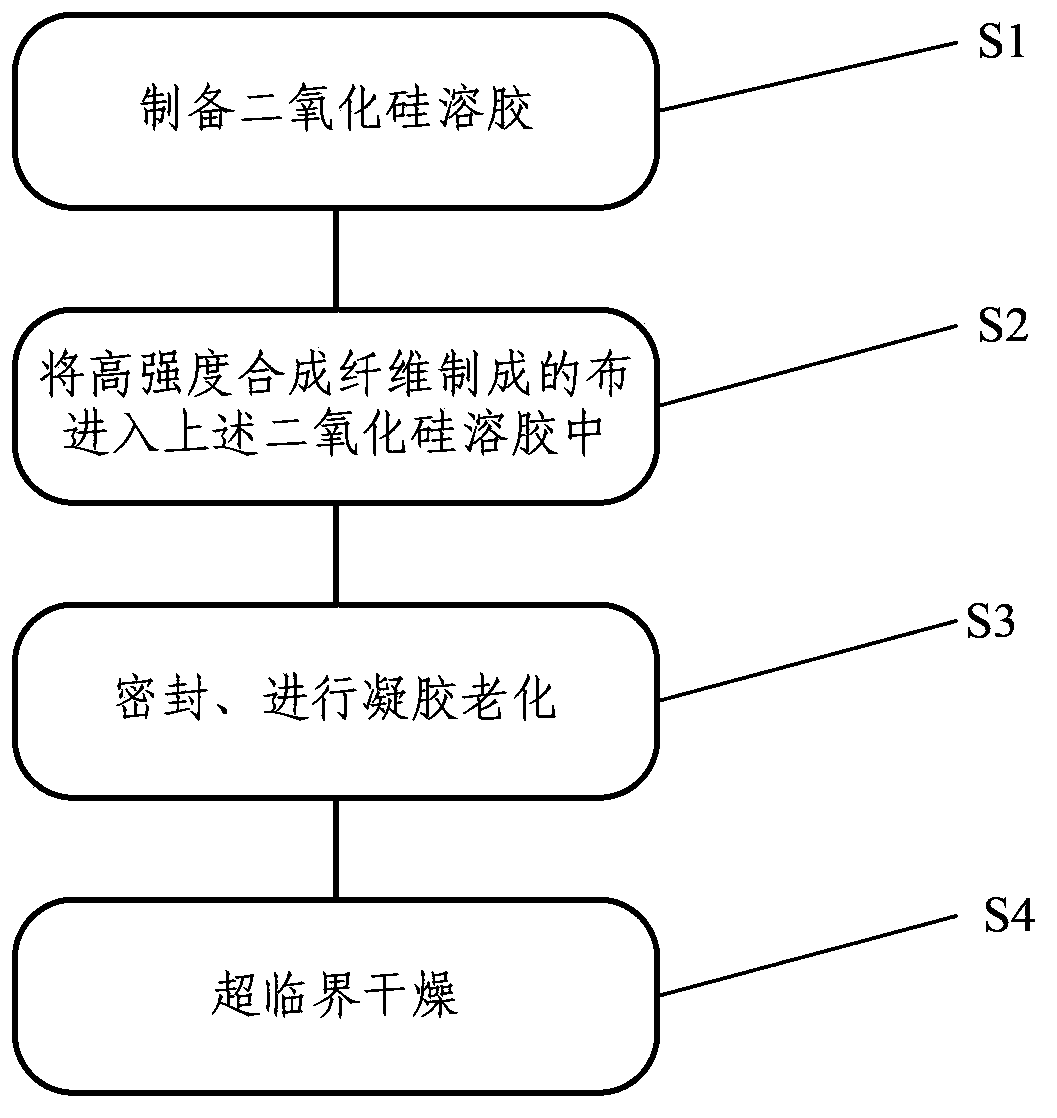

[0031] Such as figure 1 Shown, the silica airgel composite fabric preparation method provided by the invention comprises the following steps:

[0032] S1: Mix ethanol, tetraethyl orthosilicate, deionized water, ammonia water and polydimethylcyclosiloxane, and stir evenly to form a silica sol;

[0033] S2: Immerse a cloth made of high-strength synthetic fibers into the silica sol described in step S1; the high-strength synthetic fibers here can be one of aramid fibers, carbon fibers, and high-strength polyethylene fibers.

[0034] S3: After the cloth surface is completely impregnated, seal the cloth made of high-strength synthetic fibers impregnated with silica sol, and perform gel aging to obtain a silica gel molded body;

[0035] S4: Place the silica gel shaped body described in step S3 in a drying device for supercritical drying to obtain a silica airgel composite fabric.

Embodiment 1

[0038] First, 100 parts of ethanol with a concentration of 95%, 20 parts of ethyl orthosilicate (28% silicon dioxide content), 5 parts of deionized water, 3 parts of ammonia water (the content of ammonia gas is 30%), and 9 parts of polymer Dimethylcyclosiloxane (DMC) is mixed and stirred evenly to form a silica sol. Then immerse the cloth made of aramid fiber into the pre-prepared silica sol. After the cloth surface is completely soaked, it is sealed and subjected to gel aging to obtain a silica gel molded body. The aging time is 5 hours. Finally, the silica gel shaped body was placed in a drying kettle, and compressed carbon dioxide was introduced, and the temperature was adjusted to 55° C., and the pressure was adjusted to 22 MPa before drying. After the equipment drops to normal pressure, open the kettle and take out the product, and measure its relevant data: density 150kg / m 3 , Thermal conductivity at room temperature is 0.012w / (m.k). From the above data analysis, the s...

Embodiment 2

[0040] First, 100 parts of ethanol with a concentration of 99%, 10 parts of tetraethyl orthosilicate (silica content 28%), 5 parts of deionized water, 3 parts of ammonia water (the content of ammonia gas is 25%), and 3 parts of polymer Dimethylcyclosiloxane (DMC) is mixed and stirred evenly to form a silica sol. Then immerse the cloth made of carbon fiber into the pre-prepared silica sol. After the cloth surface is completely soaked, it is sealed and subjected to gel aging to obtain a silica gel molded body. The aging time is 2 hours. Finally, the silica gel shaped body was placed in a drying kettle, and compressed carbon dioxide was passed through, and the temperature was adjusted to 75° C., and the pressure was adjusted to 35 MPa, and then dried. After the equipment drops to normal temperature and pressure, open the kettle and take out the product, and measure its relevant data: the density is 120kg / m 3 , The thermal conductivity at room temperature is 0.010w / (m.k). Accord...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com