A kind of anti-high temperature modified starch fluid loss reducer and preparation method thereof

A fluid loss reducer, high temperature resistance technology, applied in chemical instruments and methods, drilling composition, fermentation, etc., can solve the problem that the temperature resistance ability is difficult to exceed 140 ℃, the salt resistance and calcium resistance are poor, and the scope of use is limited. and other problems, to achieve the effect of simple and easy preparation method, improved temperature resistance, mild and controllable reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

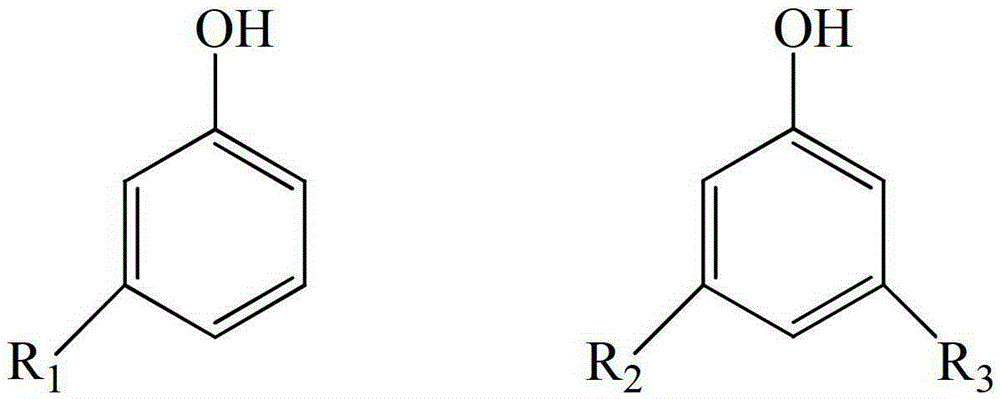

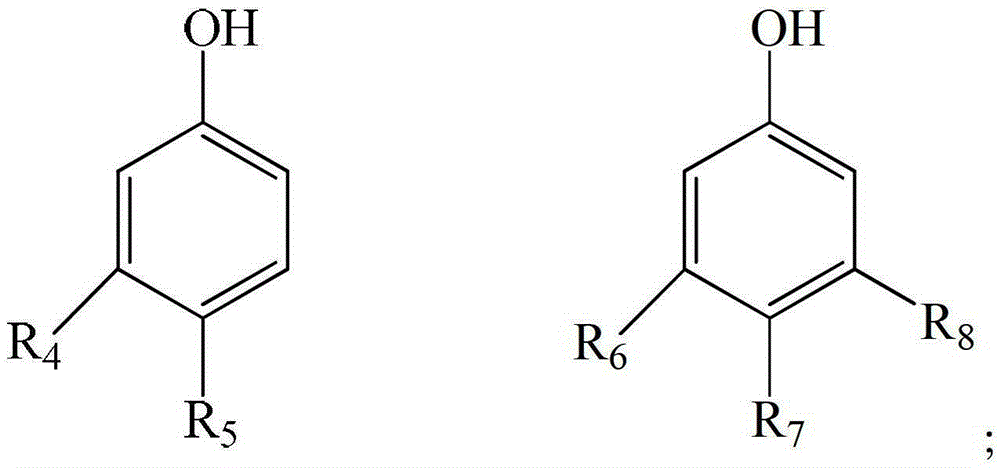

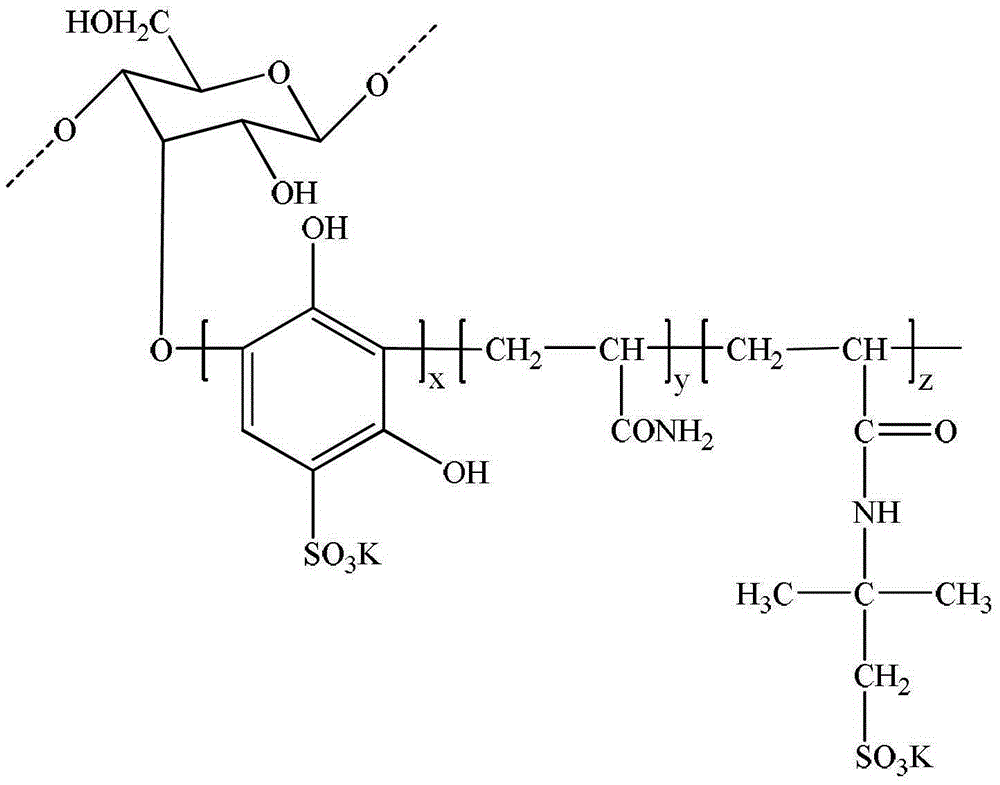

Method used

Image

Examples

preparation example Construction

[0031] A preparation method of high temperature resistant modified starch fluid loss reducer, comprising:

[0032] Dissolve alkenyl amide and alkenyl sulfonate in deionized water solvent, and adjust the pH of the solution to 6.0-8.0 with 2.0wt% NaOH or KOH aqueous solution to obtain a mixed monomer solution with a concentration of 20.0wt%-50.0wt% ;

[0033] Add the oil phase solution and the nonionic surfactant into the reactor, stir and mix to obtain an emulsion with a lipophilic and hydrophilic balance value HLB ranging from 7.0 to 9.0;

[0034] Add the enzyme-degraded starch emulsion into the emulsion, add phenolic compounds, biological enzymes and reducing substrates, and stir evenly to obtain a microemulsion with an oil / water volume ratio of 2 to 5:1;

[0035] Slowly raise the temperature of the microemulsion to 20-86°C within 0.5-3.0 hours, and mix the monomer solution with a concentration of 20.0wt%-50.0wt% and the hydrogen acceptor base whose molar weight is 0.2-1.0 t...

Embodiment 1

[0038] Add 40 g of cornstarch into a beaker filled with 100 mL of distilled water, stir well to form a paste, pour it into a reactor, and heat it in a water bath at 65°C. Under the condition of stirring, add 0.04g α-amylase, keep at constant temperature for 120min, raise the temperature of oil bath to 110°C, keep at constant temperature for 60min, and obtain the enzyme-degraded starch emulsion.

[0039] Make a 15.0wt% solution of 2-acrylamido-2-methylpropanesulfonic acid in water, neutralize it with 50.0wt% KOH solution to pH=6.0, and dry it in a vacuum oven at 20°C until constant Heavy.

[0040] 5.61 g of acrylamide and 19.34 g of potassium 2-acrylamido-2-methylpropanesulfonate were dissolved in 60 mL of water, and the pH was adjusted to 7.5 with 2.0 wt % KOH aqueous solution to obtain a mixed monomer solution.

[0041]In a reactor equipped with a temperature control device, a reflux condensing device and a constant pressure feeding device, add 400 mL of cyclohexane, then ad...

Embodiment 2

[0045] Add 40g of tapioca starch into a beaker with 40mL of distilled water, stir it into a paste, pour it into the reactor, heat it in a water bath at 96°C, add 0.008g of α-amylase under stirring, keep it at constant temperature for 120min, heat up the oil The temperature of the bath was raised to 118° C., and kept at a constant temperature for 60 minutes to obtain an enzyme-degraded starch emulsion.

[0046] Prepare a 15.0wt% solution of styrene sulfonic acid in water, neutralize it with 50.0wt% NaOH solution to pH=6.0, and dry it in a vacuum oven at 20°C to constant weight.

[0047] Dissolve 6.61 g of N,N-dimethylacrylamide and 20.62 g of sodium p-styrenesulfonate in 100 mL of water, and adjust the pH to 7.0 with 2.0 wt % NaOH aqueous solution to obtain a mixed monomer solution.

[0048] In a reactor equipped with a temperature control device, a reflux condensing device and a constant pressure feeding device, add 480 mL of toluene, then add 26.91 g of Span60 and 21.03 g of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com