A kind of processing method of printing plate with high printing force

A processing method and printing plate technology, applied in printing process, printing, printing plate and other directions, can solve the problems of poor wear resistance and low printing endurance of offset lithography, and achieve improved wear resistance, improved printing endurance and stable quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

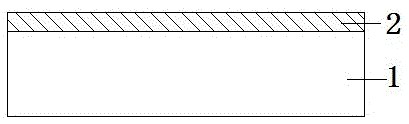

Image

Examples

Embodiment 1

[0037] (1) The 0.25mm thick cold-rolled and calendered brass layer is subjected to single-side grinding treatment to form a grain structure on the surface, and then the impurities and oil stains on the surface of the above-mentioned brass layer are removed; Roller coating coats a photosensitive layer with a thickness of 3 μm, and obtains a printing plate after drying;

[0038] (2) Use a resolution of 2400dpi and an intensity of 120mJ / cm 2 The 405nm ultraviolet laser irradiates the photosensitive layer of the above-mentioned printing plate, and after development, the brass layer is exposed at the part irradiated by the above-mentioned laser;

[0039] (3) Electroplate a layer of 0.003mm thick chromium layer on the exposed brass layer, then react with 5wt% NaOH solution to dissolve the remaining photosensitive adhesive, and obtain printing plate A after repairing and cutting.

Embodiment 2

[0041](1) The 0.4mm thick cold-rolled and calendered brass layer is subjected to single-sided grinding to form a grain structure on the surface, and then the impurities and oil stains on the surface of the above-mentioned brass layer are removed; Centrifugally coat a photosensitive layer with a thickness of 4 μm, and obtain a printing plate after drying;

[0042] (2) Use a resolution of 2500dpi and an intensity of 180mJ / cm 2 The 830nm heat-sensitive laser irradiates the photosensitive layer of the above-mentioned printing plate, and after development, the brass layer is exposed at the part irradiated by the above-mentioned laser;

[0043] (3) Electroplate a layer of 0.004mm thick chromium layer on the exposed brass layer above, then react with 8wt% NaOH solution to dissolve the remaining photosensitive adhesive, and obtain printing plate B after repairing and cutting.

Embodiment 3

[0045] (1) The 0.5mm thick cold-rolled calendered copper layer is subjected to single-side grinding treatment to form a grain structure on the surface, and then the impurities and oil stains on the surface of the above-mentioned copper layer are removed; then glue is applied on the ground-treated side Coating a photosensitive layer with a thickness of 5 μm, and drying to obtain a printing plate;

[0046] (2) Use a resolution of 2500dpi and an intensity of 240mJ / cm 2 The 830nm thermal laser irradiates the photosensitive layer of the above-mentioned printing plate, and after development, the copper layer is exposed at the part irradiated by the above-mentioned laser;

[0047] (3) Electroplate a layer of 0.005mm thick chromium layer on the above exposed part of the copper layer, then react with 10wt% NaOH solution to dissolve the remaining photosensitive adhesive, and obtain the printing plate C after repairing and cutting.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com