Cationic polymerization imaging composition for high-sensitive photopolymerization plate

An imaging composition and a technology of cationic polymerization, which are applied in the field of cationic polymerization imaging photosensitive compositions, can solve the problems of increasing operation steps and increasing costs, and achieve the effects of high sensitivity, high printing durability and good resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

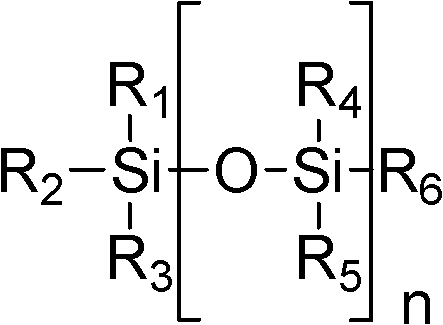

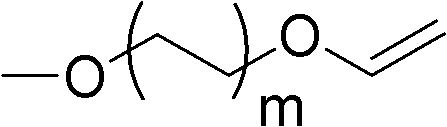

Method used

Image

Examples

preparation Embodiment 1

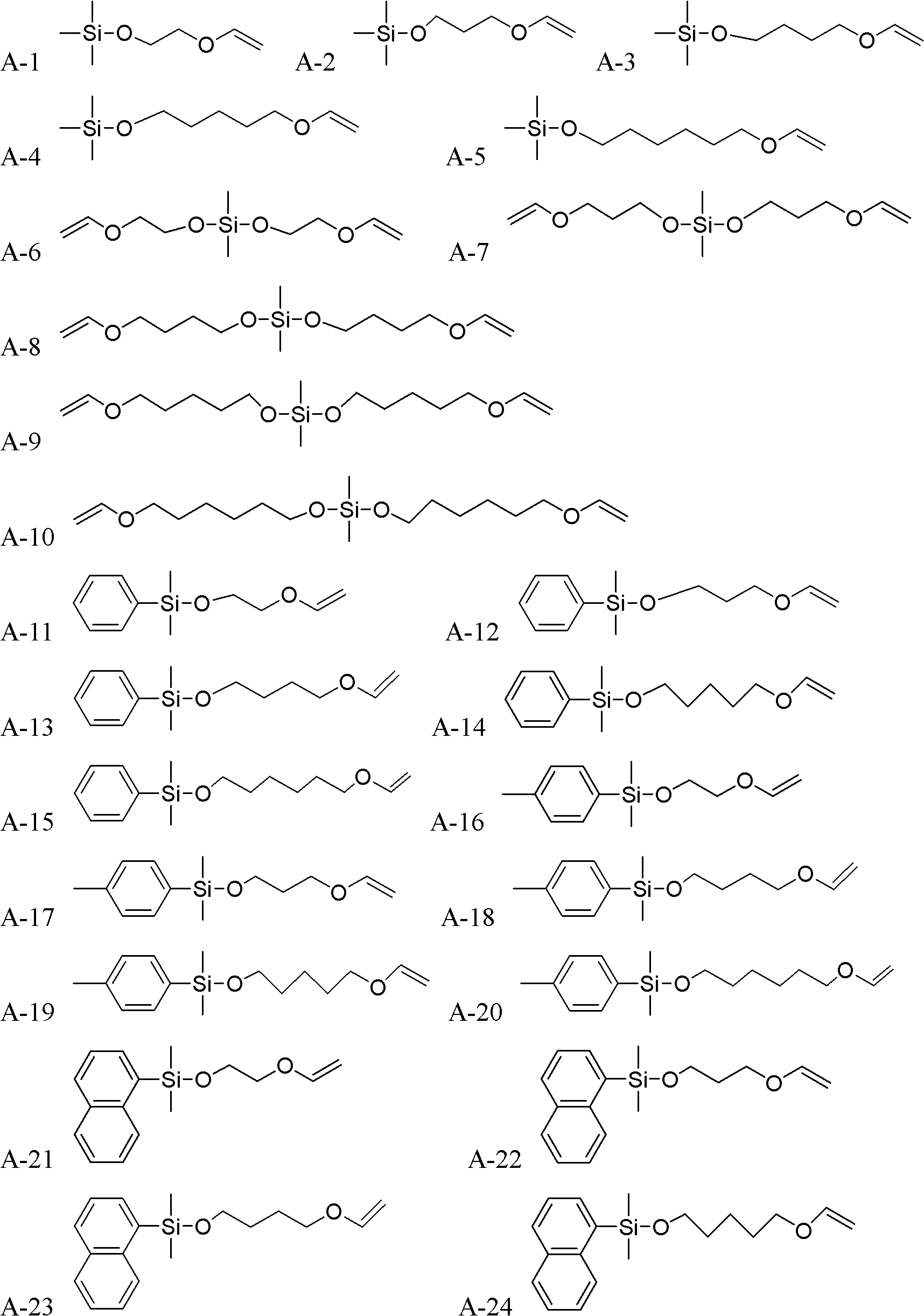

[0039] Monomer A-13, That is, the synthetic method of 1-phenyl-1-vinyloxybutoxydimethylsilane:

[0040] Take a three-necked flask, add 8.5mL (0.0522mol) of 1-phenyldimethylchlorosilane to 200mL of tetrahydrofuran under nitrogen atmosphere, 16mL (0.1148mol) of triethylamine, magnetically stir, ice-water bath, and then add 4-hydroxybutyl Dissolve 13.5mL (0.1096mol) of vinyl ether in 80mL tetrahydrofuran, and add slowly dropwise; after the dropwise addition, remove the ice-water bath, return to room temperature and stir for 2 hours; filter, spin evaporate the solvent, and use 50mL n-hexane After extraction and filtration, the filtrate was concentrated at 70°C, and the concentrated product was decompressed with an oil pump to remove low-boiling impurities to obtain a colorless transparent liquid as a pure product with a yield of 79%.

preparation Embodiment 2

[0042] monomer That is, the synthesis of 1,1-diphenyl-7-vinyloxyethoxyheptamethyltetrasiloxane):

Embodiment 1

[0045] Get the BTB-26 m-cresol-formaldehyde resin (M W =4000, M n =1500)35g, add self-synthesized Photosensitive monomer 15g, mixed triaryl hexafluoroantimonate sulfonium salt PAG201 (provided by Changzhou Qiangli Electronic New Material Co., Ltd.) 0.5g, basic brilliant blue 0.1g, acetone 300g; first the resin was dissolved in acetone, stirred to make After it is completely dissolved, other components are added, and then filtered through filter cores with pore sizes of 10 μm, 5 μm, and 0.5 μm in sequence to obtain the cationic polymerization imaging composition PCL-1 for high-sensitivity photopolymerization plates.

[0046] A 1% NaOH aqueous solution was used as a developer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com