Protective solution for CTP plate material in the baking process

A technology of protective liquid and plate material, applied in the field of printing plate material production, which can solve the problems of reduced printing suitability of plate material, limited protective effect of baked plate, large dot deformation rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

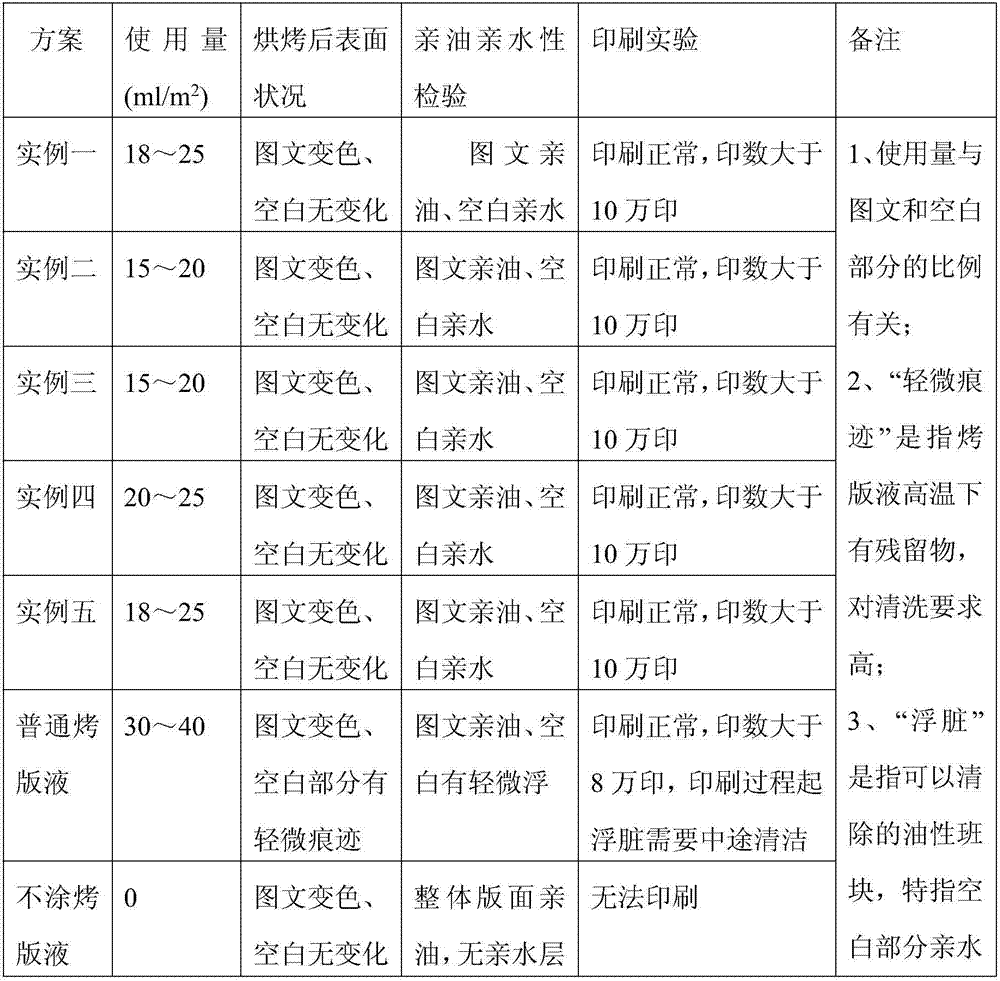

Examples

Embodiment 1

[0012] Example 1: A protective solution for CTP plate baking, including the following raw materials in mass fractions: ammonium pentaborate 1.0-5.0%, ammonium tetraborate 0.5-2.0%, TX-100.3-0.5%, NP-100.2-0.5% %, 0.5-1.2% of alkyl diphenyl ether disulfonate, and the balance is water; wherein, TX-10+NP-10: alkyl diphenyl ether disulfonate=1:1.0-1.2.

[0013] Its preparation method comprises the following steps:

[0014] (1) add borate, anionic surfactant and nonionic surfactant to water successively, all carry out stirring and dissolving after adding each time, make it mix evenly;

[0015] (2) Filter and remove slag from the above solution with a 10um filter element to obtain a colorless and transparent protective solution;

[0016] Its use method includes the following steps:

[0017] (1) Take the CTP plate after the development process (produced by Jinruitai Technology Co., Ltd., JRT200-8 positive thermal CTP plate), scrape off the excess water on the plate, and then evenly...

Embodiment 2

[0020] Embodiment 2: A protective solution for CTP plate baking, including the following raw materials in mass fractions: sodium tetraborate 1.0-3.0%, ammonium pentaborate 1.0-3.0%, NP-100.5-1.0%, fatty alcohol polyoxyethylene Ether sulfosuccinic acid half ester disodium salt 0.3-0.6%, alkyl ether sulfosuccinic acid sodium 0.3-0.6%, the balance is water; among them, NP-10: fatty alcohol polyoxyethylene ether sulfosuccinic acid half Ester disodium salt + sodium alkyl ether sulfosuccinate = 1: 1.0 ~ 1.2.

Embodiment 3

[0021] Embodiment 3: a kind of protective solution for baking CTP plates, including the following raw materials in mass fraction: ammonium tetraborate 2.0~5.0%, ammonium fluoroborate 1.0~2.0%, NP-100.3~0.5%, AEO-9 0.2~ 0.5%, alkyl diphenyl ether disulfonate 0.3-0.6%, sodium dodecylbenzene sulfonate 0.3-0.6%, the balance is water; among them, NP-10+AEO-9: alkyl diphenyl ether Disulfonate+sodium dodecylbenzenesulfonate=1:1.0~1.2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com