Water-based ink printing plate material and preparation method for same

A water-based ink and plate material technology, applied in printing plate preparation, lithographic printing equipment, printing plates, etc., can solve the problems that the principle of mutual exclusion of water and oil cannot be realized, and the graphic area and the non-graphic area cannot be distinguished, etc., to achieve printing Good adaptability, enhanced hydrophobicity and oleophobicity, and high printing durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

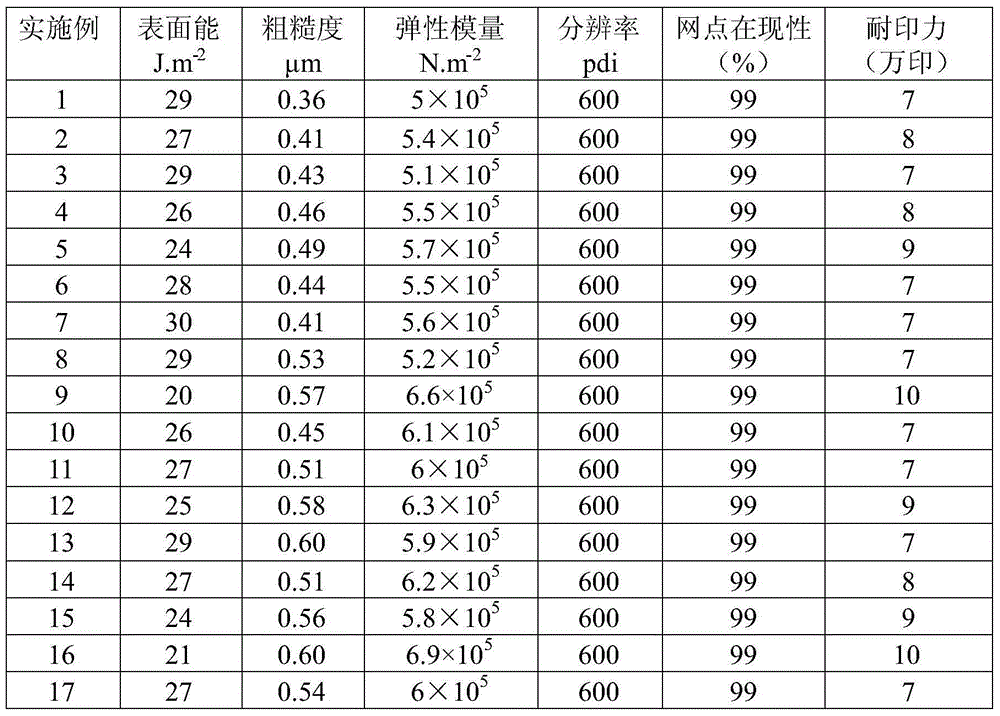

Examples

Embodiment 1

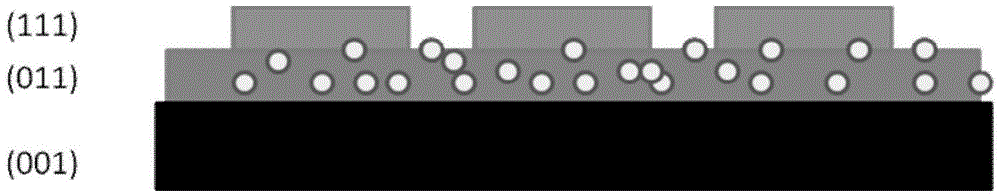

[0025] The plate material for water-based ink prepared in this example has the structure of a plate base, an ink repellent layer, and a graphic layer from bottom to top.

[0026] The material of the plate base is selected from aluminum.

[0027] The ink repellent layer is coated on the plate base by the fluorosilicon nanocomposite material with a spin coater at a speed of 4500rpm, and the coating amount is 2.5g.m -2 ; Then it is obtained after curing at 200°C for 20min, and the base is degreasing before coating. Finally, the contact angles were measured with water and diiodomethane.

[0028] The graphic layer is made by inkjet printing on the surface of the ink repellent layer, and the spraying amount is 1g.m -2 , and then obtained after curing at 150 °C for 20 min.

[0029] The preparation method of the fluorosilicon nanocomposite material: add 1 g of perfluoroalkyl ethyl acrylate and 0.2 g of propyl methacrylate into a three-necked flask, and then add 12 g of methyl ethyl...

Embodiment 2

[0032] The plate material for water-based ink prepared in this example has the structure of a plate base, an ink repellent layer, and a graphic layer from bottom to top.

[0033] The material of the plate base is selected from aluminum.

[0034] The ink repellent layer is coated on the plate base by the fluorosilicon nanocomposite material with a spin coater at a speed of 4500rpm, and the coating amount is 2.8g.m -2 ; Then it is obtained after curing at 200°C for 20min, and the base is degreasing before coating. Finally, the contact angles were measured with water and diiodomethane. The graphic layer is made by inkjet printing on the surface of the ink repellent layer, and the spraying amount is 1.3g.m -2 , and then obtained after curing at 150 °C for 20 min.

[0035]The preparation method of the fluorosilicon nanocomposite material: add 1 g of perfluoroalkyl ethyl acrylate and 0.2 g of propyl methacrylate into a three-necked flask, then add 12 g of methyl ethyl ketone solv...

Embodiment 3

[0038] The plate material for water-based ink prepared in this example has the structure of a plate base, an ink repellent layer, and a graphic layer from bottom to top.

[0039] The material of the plate base is selected from aluminum alloys.

[0040] The ink repellent layer is coated on the plate base by the fluorosilicon nanocomposite material with a spin coater at a speed of 4500rpm, and the coating amount is 2.6g.m -2 ; Then it is obtained after curing at 200°C for 20min, and the base is degreasing before coating. Finally, the contact angles were measured with water and diiodomethane.

[0041] The graphic layer is made by inkjet printing on the surface of the ink repellent layer, and the spraying amount is 1.5g.m -2 , and then obtained after curing at 150 °C for 20 min.

[0042] The preparation method of the fluorosilicon nanocomposite material: add 1 g of perfluoroalkyl ethyl acrylate and 0.2 g of propyl methacrylate into a three-necked flask, then add 12 g of methyl ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com