A method for circular seam laser-gma composite welding

A -GMA, composite welding technology, applied in the direction of laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of discontinuous formation of the back of the weld, incomplete penetration, and the next trip of liquid metal, so as to shorten the working cycle, The effect of sufficient flow and continuous forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

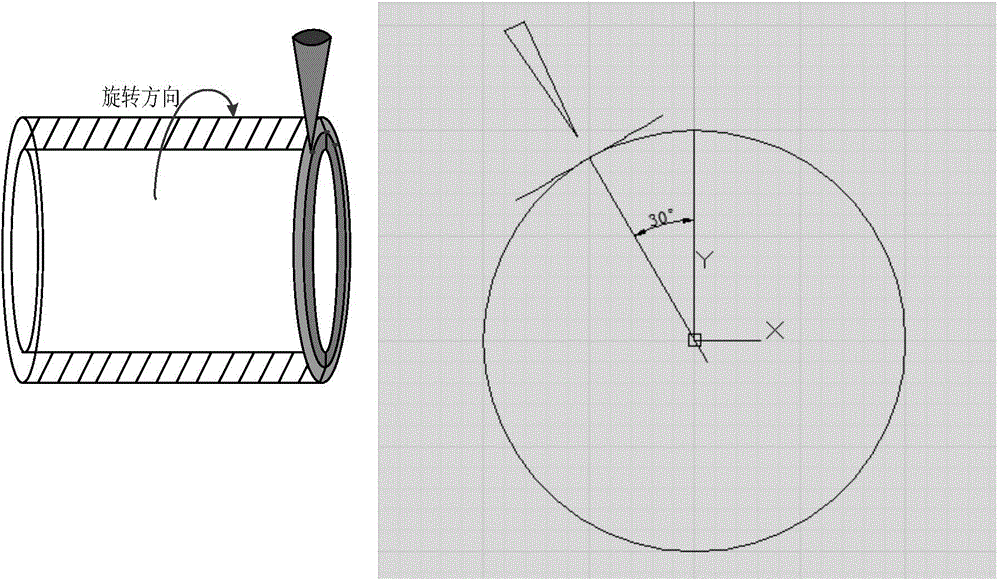

[0021] Specific implementation mode 1: The method for circular seam laser-GMA composite welding in this implementation mode is realized according to the following steps:

[0022] 1. Groove processing: machine the butt joint of the parts to be welded to produce a Y-shaped groove with a groove angle of 30-70° and a blunt edge size of 3-8mm, and then use mechanical grinding to remove the groove surface Oxide layer, and then use acetone to clean the oil on the groove surface;

[0023] 2. Spot solidification: Use a single laser to spot solidify the blunt edge of the weld groove at two positions 180° apart from each other on the girth weld. The spot solid laser power is 500-2000W, and the light emission time is 1-2s;

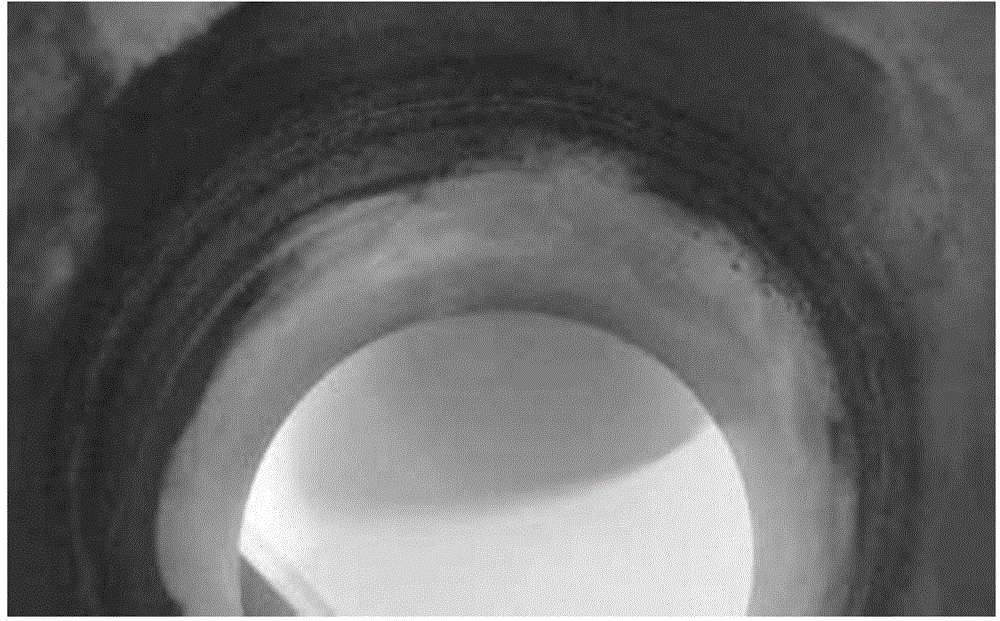

[0024] 3. Welding: Set the process parameters, the laser beam and the GMA welding torch form an angle of 45°, the incident point of the laser beam is positioned at the 11 o'clock position of the circular seam, and the distance between the laser beam and the arc heat s...

specific Embodiment approach 2

[0029] Embodiment 2: The difference between this embodiment and Embodiment 1 is that in Step 1, the bevel angle is 45°, and the size of the blunt edge is 4mm. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0030] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the power of the spot-fixed laser in step 2 is 1000W, and the light emitting time is 1.5s. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com