Multi-shaft common-rail pulse liquid micro-refinement apparatus

A miniaturization and pulse technology, applied in fluid mixers, transportation and packaging, chemical instruments and methods, etc., can solve the problem of backward micronization control technology of material particle size, poor performance of equipment and process technology, and unreachable product quality To solve the problems of users and other problems, achieve the effect of solving product agglomeration and interference of chemical agents, easy application, and improving production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

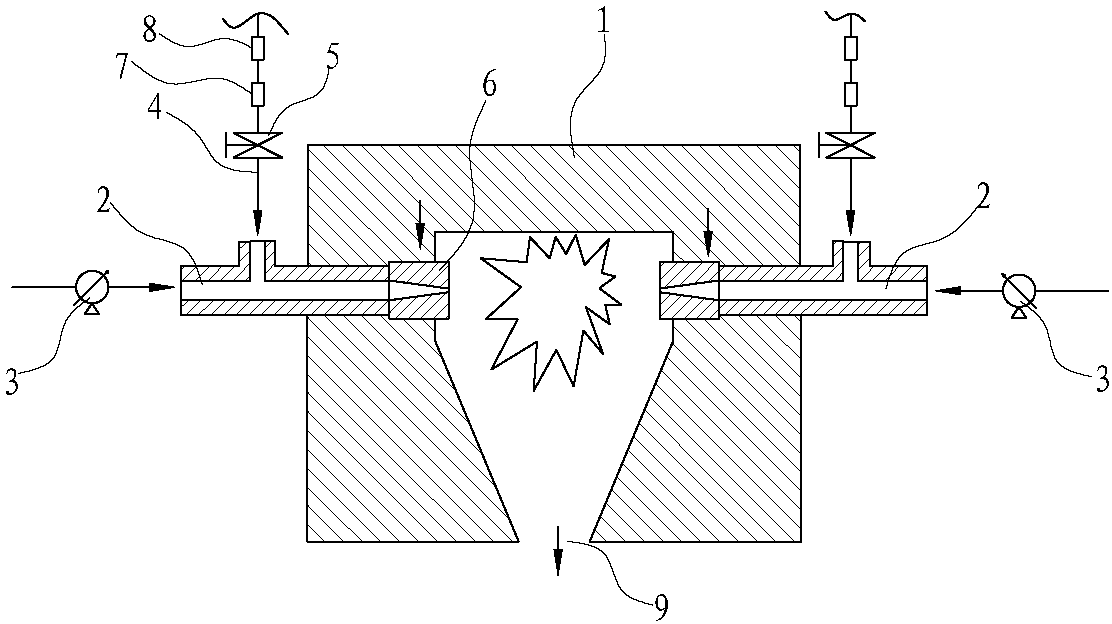

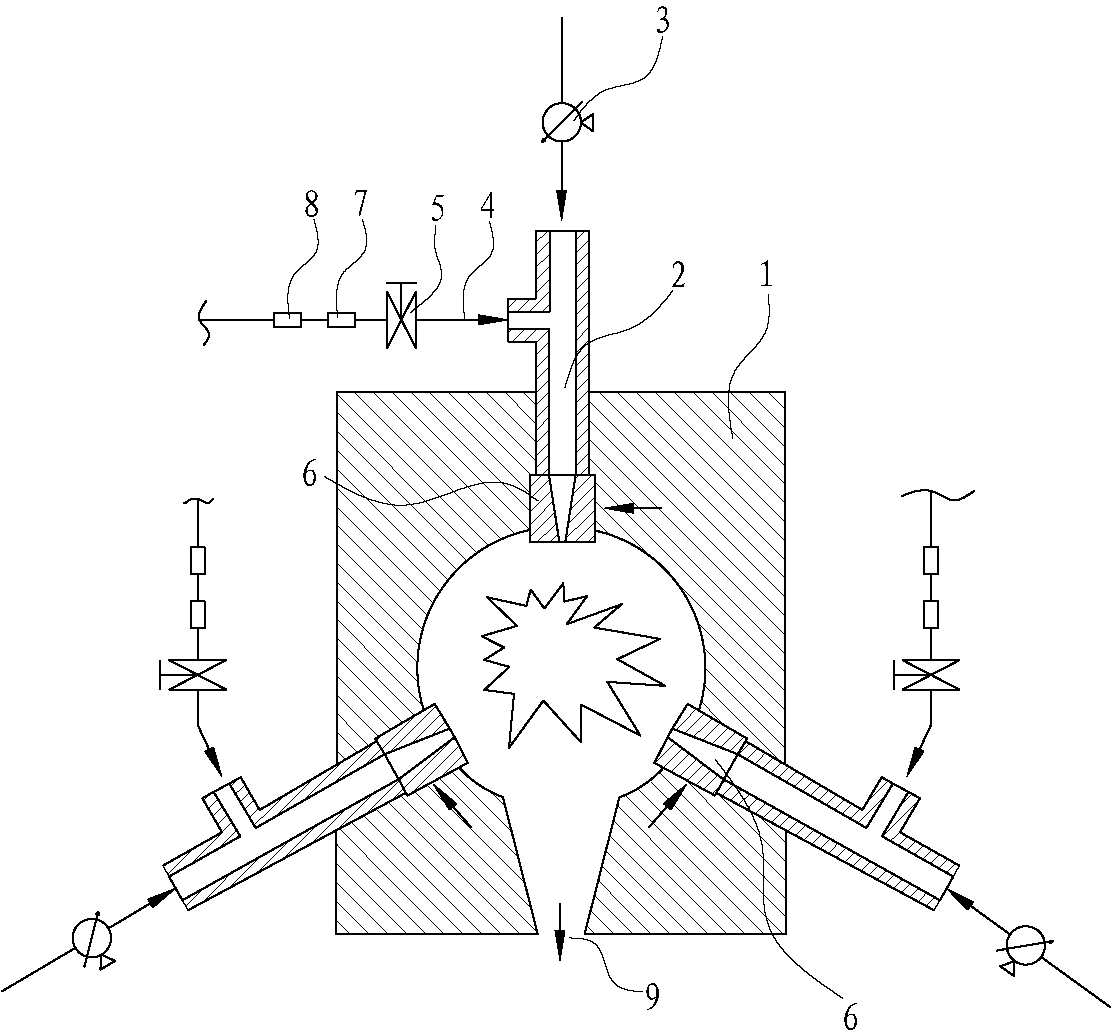

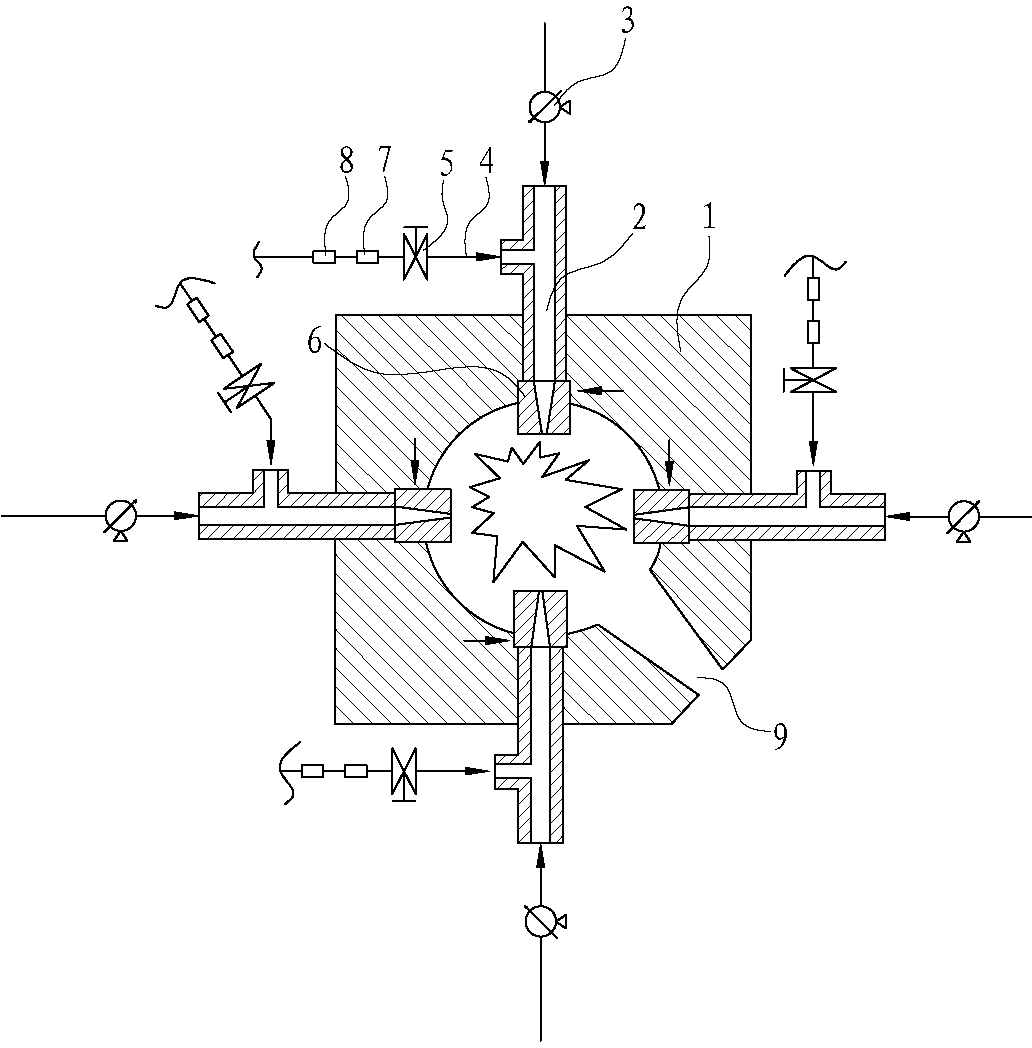

[0021] like Figure 1 to Figure 4 As shown, a multi-axis common rail pulse liquid miniaturization device disclosed by the present invention includes a miniaturization chamber 1 , more than two pipelines 2 and a high-pressure pump 3 . The refinement chamber 1 can be made of multi-component alloy steel, artificial diamond or other metals. The size and shape of the refinement chamber 1 are determined according to the design pressure and flow rate. Two or more pipelines 2 are installed on the refinement chamber 1. One end of 2 is located outside the refinement chamber 1 and has a three-way structure, and is respectively connected to the high-pressure pump 3 and the slurry raw material pipe 4. The valve 5 is installed on the slurry raw material pipe 4, and the other end of the pipeline 2 is located in the refinement chamber 1 and installed with a nozzle. 6. The key of the present invention is that the central axes of the nozzles 6 meet together in the refining chamber 1, and the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com