Surface graphene-coated high-capacity spherical hard carbon negative electrode material

A technology of graphene coating and negative electrode materials, which is applied in the direction of graphene, battery electrodes, electrical components, etc., can solve the problems of low initial efficiency, large irreversible capacity of hard carbon, and restrictions on the wide application of hard carbon, so as to achieve stable product properties, Excellent electrochemical performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

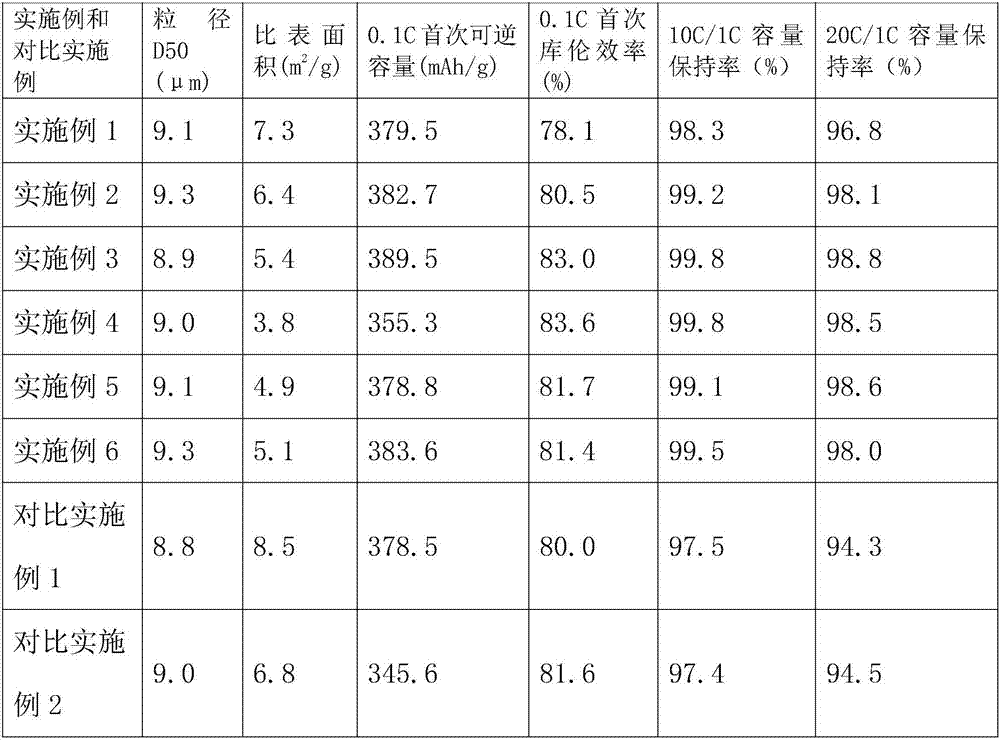

Examples

Embodiment 1

[0025] (1) Under stirring, add coumarone resin, paraformaldehyde and p-toluenesulfonic acid into the reaction kettle with a mass ratio of 20:12:1, mix evenly, and heat up to 180°C under nitrogen atmosphere and stirring conditions for exchange Copolymerize for 4 hours, cool down to room temperature and discharge to obtain a polymerized reactant, and ball mill and sieve the polymerized reactant to obtain a hard carbon precursor with a D50 particle size of 10-15 μm;

[0026] (2) The hard carbon precursor was treated with dimethyl silicone oil at 250°C to prepare the crude polymer microspheres, cooled to room temperature and discharged, washed with ethanol to remove the silicone oil on the surface of the crude polymer microspheres, and then dried to obtain polymer microspheres;

[0027] (3) Polymer microspheres were oxidized at 260° C. for 1 h in an air atmosphere, cooled to room temperature, and discharged to obtain infusible microspheres; then they were loaded into a well-type f...

Embodiment 2

[0031] (1) Add coumarone resin, paraformaldehyde and p-toluenesulfonic acid to the reaction kettle with a mass ratio of 20:12:1 under stirring, mix well, and heat up to 180°C under nitrogen atmosphere and stirring conditions for crosslinking Polymerize for 4 hours, cool down to room temperature and discharge to obtain a polymerized reactant, and ball mill and sieve the polymerized reactant to obtain a hard carbon precursor with a D50 particle size of 10-15 μm;

[0032] (2) The hard carbon precursor was treated with dimethyl silicone oil at 250°C to obtain the crude polymer microspheres, cooled to room temperature and discharged, washed with ethanol to remove the silicone oil on the surface of the crude polymer microspheres, and then dried to obtain polymer microspheres;

[0033] (3) The polymer microspheres were oxidized at 260°C for 1 hour in an air atmosphere, cooled to room temperature, and discharged to obtain infusible microspheres; they were then put into a well-type fur...

Embodiment 3

[0037](1) Add coumarone resin, paraformaldehyde and p-toluenesulfonic acid to the reaction kettle with a mass ratio of 20:12:1 under stirring, mix well, and heat up to 180°C under nitrogen atmosphere and stirring conditions for crosslinking Polymerize for 4 hours, cool down to room temperature and discharge to obtain a polymerized reactant, and ball mill and sieve the polymerized reactant to obtain a hard carbon precursor with a D50 particle size of 10-15 μm;

[0038] (2) The hard carbon precursor was treated with dimethyl silicone oil at 250°C to obtain the crude polymer microspheres, cooled to room temperature and discharged, and the silicone oil on the surface of the crude polymer microspheres was washed with ethanol and dried to obtain polymer microspheres;

[0039] (3) Polymer microspheres were oxidized at 260°C for 1 hour in an air atmosphere, cooled to room temperature, and discharged to obtain infusible microspheres; they were then put into a well-type furnace and heat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com