Method for preparing mesoporous AgGaO2 photocatalytic material

A photocatalytic material and mesoporous technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc. Photocatalytic materials, limiting solar energy utilization and other issues, to achieve the effect of improving photocatalytic activity, good reproducibility, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

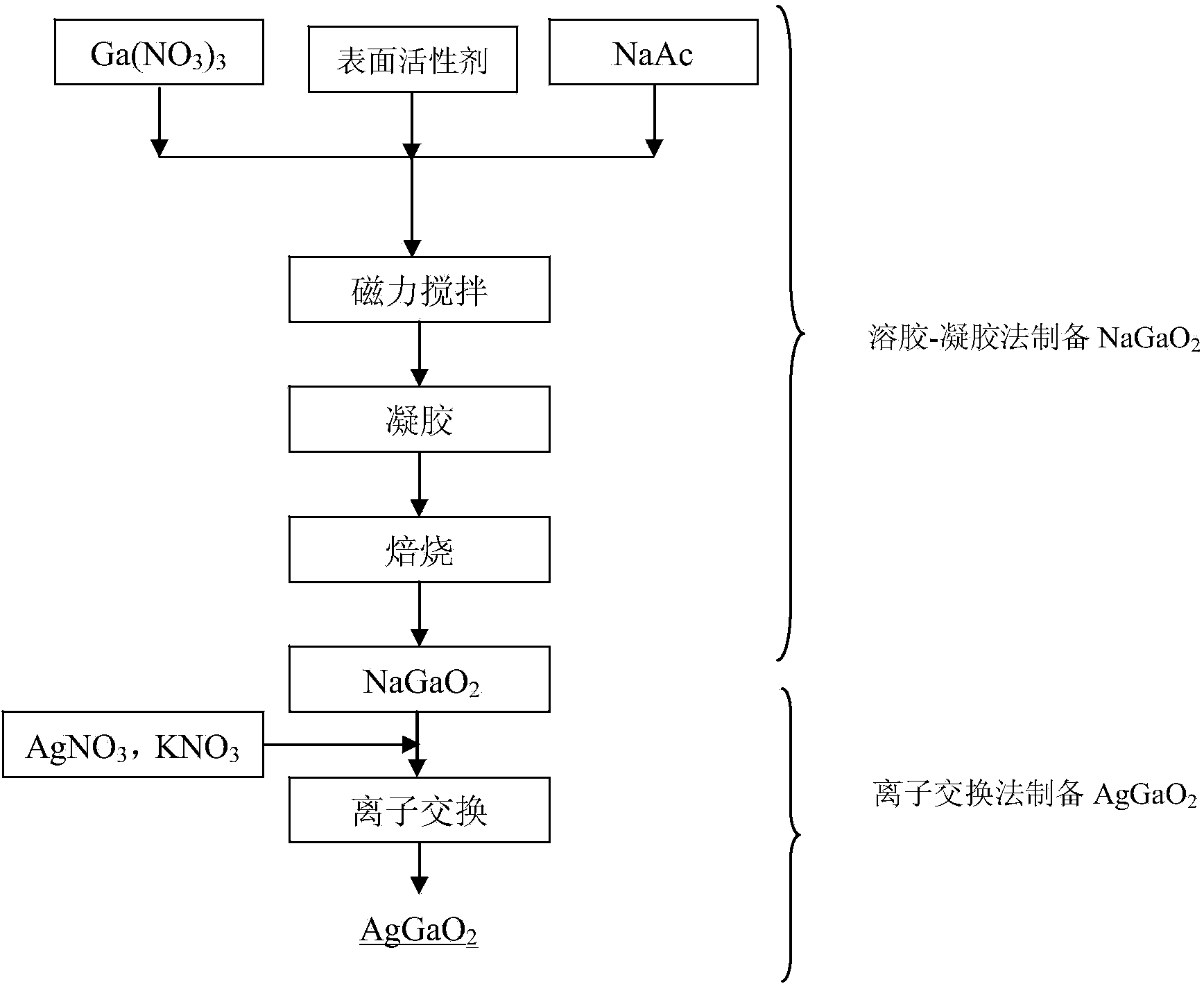

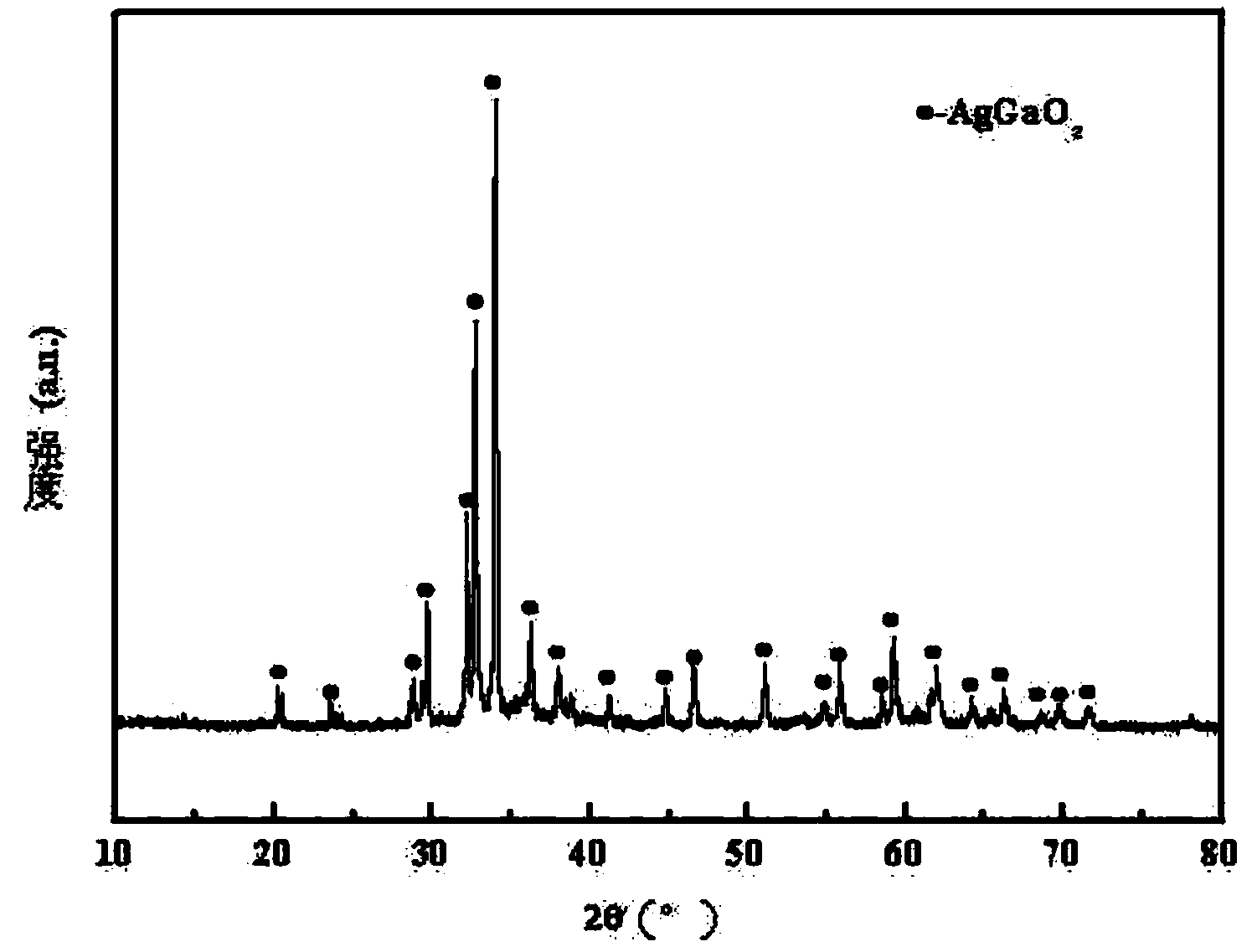

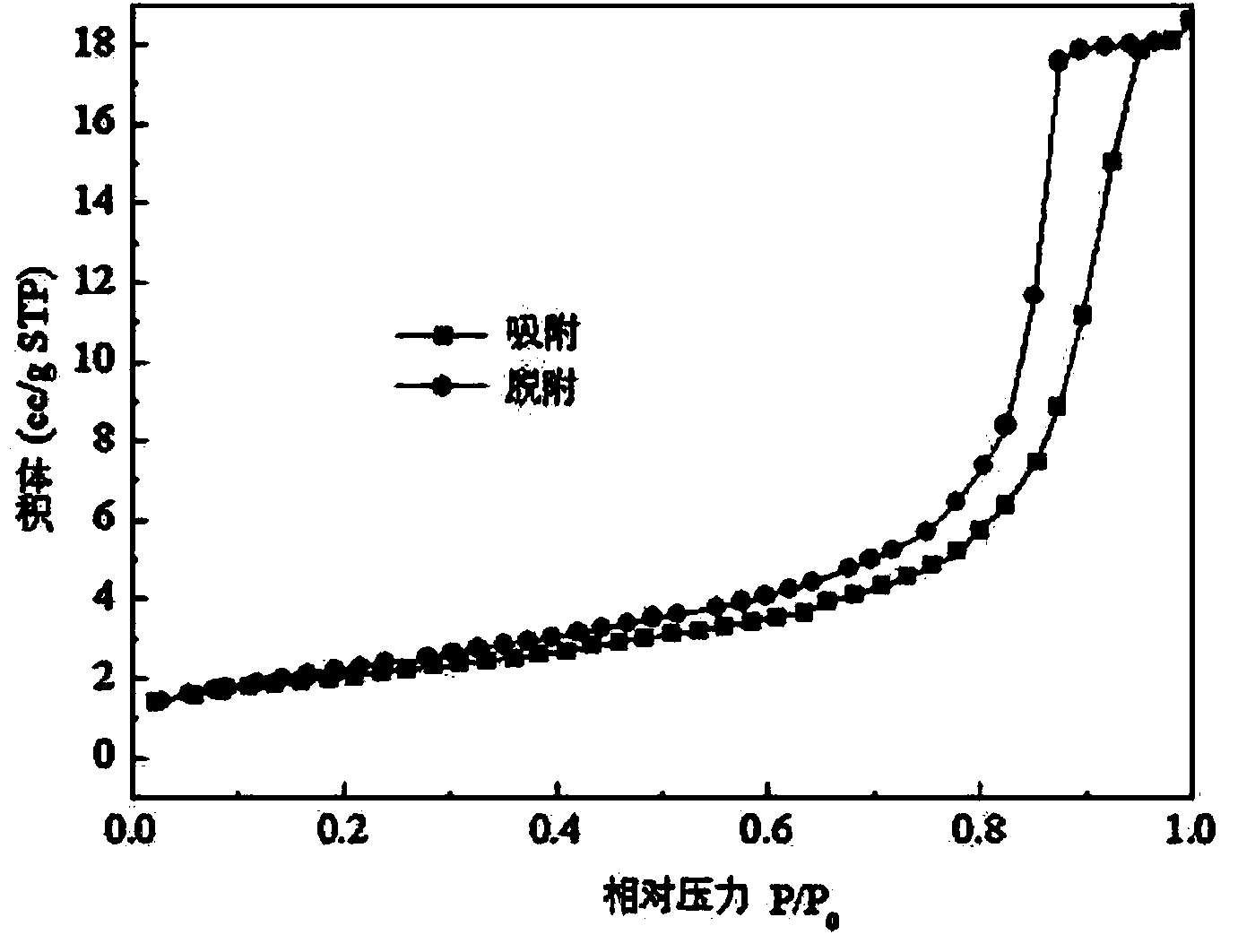

[0026] in CH 3 COONa·3H 2 O and Ga(NO 3 ) 3 ·8H 2 O as raw material, weigh 0.03mol CH 3 COONa·3H 2 O and 0.015mol Ga(NO 3 ) 3 ·8H 2O, dissolved in 60ml of ethylene glycol, added 1g of surfactant P123, stirred with a glass rod for 10min to fully dissolve, stirred in a water bath at 70°C for 5h, dried the obtained gel at 190°C for 12h, and finally at 850°C Calcined for 5h to obtain white mesoporous NaGaO 2 powder. The resulting mesoporous NaGaO 2 , AgNO 3 、KNO 3 According to the molar ratio of 1:1.5:1, mix and grind in an agate mortar for 10 minutes, transfer the mixture to a corundum crucible, and calcinate at 210°C for 20 hours. The obtained product is washed with deionized water, centrifuged, and placed in an oven. Dry at 80°C and grind to obtain mesoporous AgGaO 2 photocatalytic material. figure 2 For the prepared AgGaO 2 XRD pattern, all the diffraction characteristic peaks in the figure are consistent with AgGaO 2 (JCPDS, No.21-1076) is consistent with th...

Embodiment 2

[0028] in CH 3 COONa·3H 2 O and Ga(NO 3 ) 3 ·8H 2 O as raw material, weigh 0.03mol CH 3 COONa·3H 2 O and 0.015mol Ga(NO 3 ) 3 ·8H 2 O, dissolve in 60ml of ethylene glycol, add 1g of surfactant CTAB, stir with a glass rod for 10min to fully dissolve, stir in a water bath at 70°C for 5h, dry the obtained gel at 190°C for 12h, and finally at 850°C Calcined for 5h to obtain white mesoporous NaGaO 2 powder. The resulting mesoporous NaGaO 2 , AgNO 3 、KNO 3 Mix and grind in an agate mortar for 10 minutes according to a molar ratio of 1:1:1, transfer the mixture to a corundum crucible, and calcinate at 210°C for 20 hours. The obtained product is washed with deionized water, centrifuged, and placed in an oven Dry at 80°C and grind to obtain mesoporous AgGaO 2 photocatalytic material. Figure 4 Embodiment 1 of the present invention, product obtained in 2 and P25 (commercial TiO 2 , generally used to compare the photocatalytic effect of synthetic photocatalytic materials)...

Embodiment 3

[0030] in CH 3 COONa·3H 2 O and Ga(NO 3 ) 3 ·8H 2 O as raw material, weigh 0.03mol CH 3 COONa·3H 2 O and 0.015mol Ga(NO 3 ) 3 ·8H 2 O, dissolved in 60ml of ethylene glycol, added 1g of surfactant F127, stirred with a glass rod for 10min to fully dissolve, stirred in a water bath at 70°C for 5h, and a gel was obtained. The resulting gel was dried at 190 °C for 12 h, and finally calcined at 850 °C for 5 h to obtain white mesoporous NaGaO 2 powder. The resulting mesoporous NaGaO 2 , AgNO 3 、KNO 3 According to the molar ratio of 1:1:2, mix and grind in an agate mortar for 10 minutes, transfer the mixture to a corundum crucible, and calcinate at 210°C for 20h. The obtained product is washed with deionized water, centrifuged, and placed in an oven at 80°C Dry and grind to obtain mesoporous AgGaO 2 photocatalytic material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com