Method for processing PCB with step groove

A PCB board and processing method technology, applied in the field of PCB board manufacturing, can solve problems such as retention in holes, PCB board damage, delamination explosion, etc., to achieve the effect of ensuring flatness and avoiding circuit short circuit or open circuit of PCB board

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

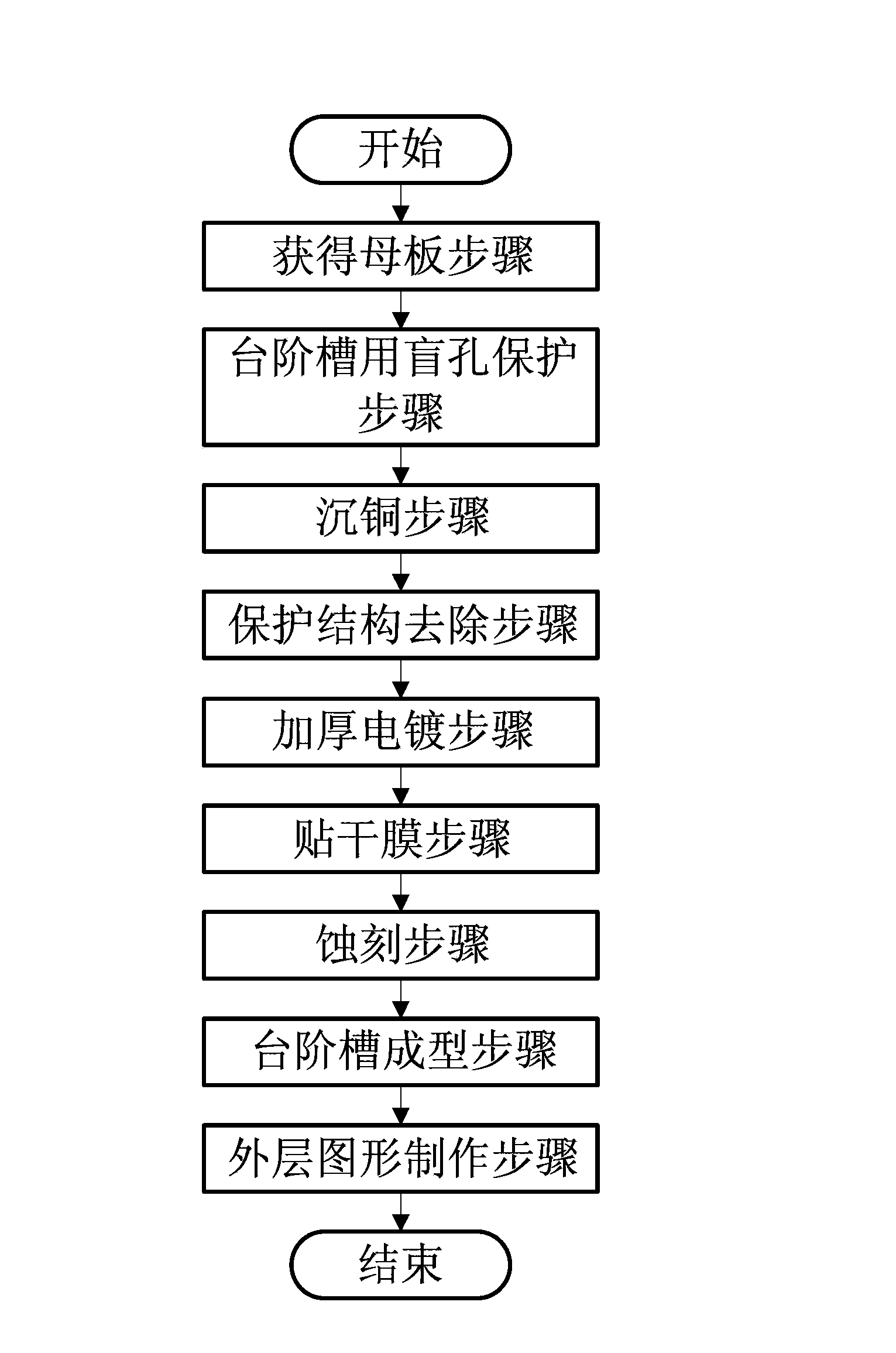

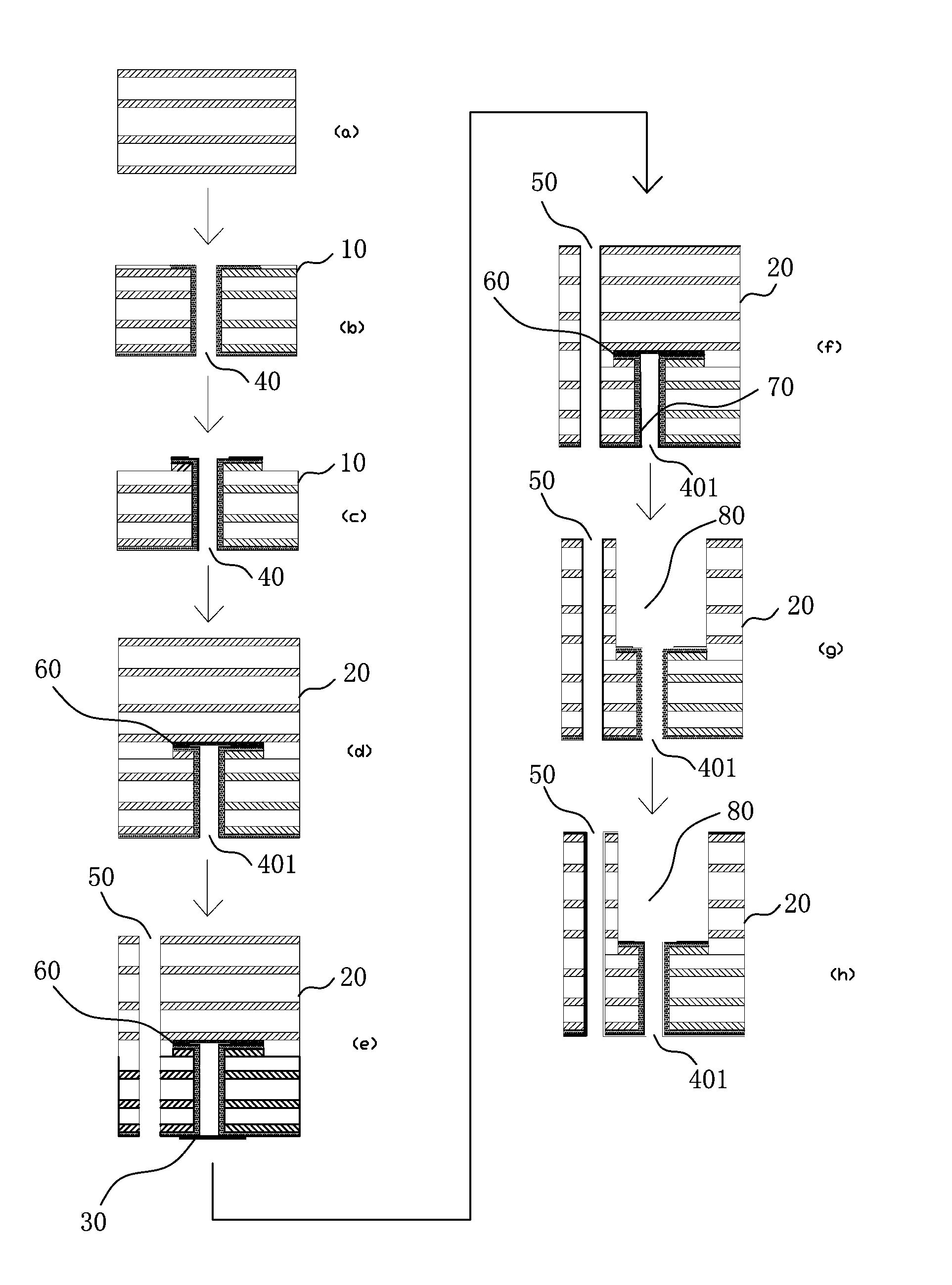

[0016] The processing method of the PCB board with stepped grooves in the embodiment of the present invention is mainly to pre-coat the bottom edge and hole wall of the blind hole with the stepped groove with a resist layer, and set the protective structure on the stepped groove before the mother board sinks copper. Use the hole of the blind hole, remove the copper after sinking, effectively prevent the highly corrosive copper sinking solution from penetrating into the blind hole for the step groove and the graphic area at the bottom of the step groove and ensure the surface of the circuit board in the subsequent electroplating process Uniformity of copper thickness (the step of sinking copper usually only forms a copper layer with a thickness of a few microns, which does not affect the consistency of the thickness of the copper layer after subsequent electroplating, so it does not affect the transmission of signals after the formation of subsequent lines), and at the same time,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com